Elevate Your Furniture with Luyao Precision

PVC Edge Banding Glue supplier

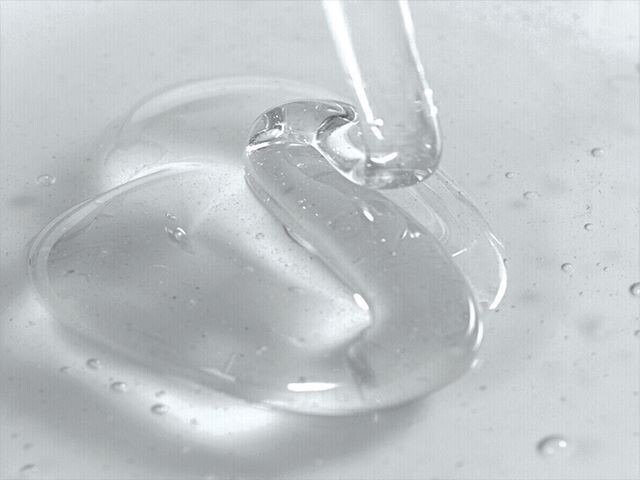

For furniture manufacturers, the difference between a product that impresses and one that disappoints often lies hidden in the details – specifically, the edge banding. And the unsung hero ensuring that seamless, durable, and beautiful edge finish is the PVC edge banding glue. At Shanghai Luyao Industry Co., Ltd., we don’t just supply glue; we engineer the foundation of exceptional furniture edges. For over 20 years, we’ve been empowering factories worldwide with high-performance adhesives designed for modern edge banding machines.

Luyao Industrial Strength

Walk through our 25,000 sq. meter state-of-the-art facility in Shanghai, and you witness the engine of our reliability:

- Advanced Polymer Labs

- Dedicated Production Lines

- Rigorous QC Protocol

- Automated Packaging

- Global Logistics Hub

Choosing with Confidence

Navigating the Glue Landscape: EVA vs. PUR

EVA Hot melt adhesive

Thermoplastic – melts when heated, solidifies on cooling. Can be remelted.

- Cost-Effectiveness: Lower material cost per meter bonded. Ideal for high-volume, standard furniture.

- Ease of Use: Simple application and cleanup on edge banding machines with standard glue pots. Minimal sensitivity to ambient moisture.

- Fast Processing: Excellent for high-speed production lines.

- Versatility: Wide range of formulations (filled/unfilled, colors).

PUR Hot melt adhesive

Thermoplastic initially, then reacts irreversibly with atmospheric moisture to form thermosetting cross-links. Cannot be remelted.

- Exceptional Water & Moisture Resistance: Passes stringent 72-hour+ water immersion tests (EN 205 / ASTM D1183). Essential for kitchens, bathrooms, outdoor applications.

- Superior Heat Resistance: Withstands temperatures exceeding 120°C (248°F) after full cure (7 days), resisting boiling water spills and dishwasher steam.

- Unrivaled Chemical Resistance: Holds strong against common household cleaners, oils, and mild solvents.

- Enhanced Bond Strength & Flexibility: Creates a tougher, more flexible bond resistant to impact and substrate movement (wood expansion/contraction). Reduces delamination risk significantly.

- Gap-Filling Superiority: Excellent performance on slightly uneven surfaces.

Glue Temperature Classification Matters

Applying PVC edge banding glue at the correct temperature is paramount for optimal bond strength and machine performance.

Low-Temperature Adhesives

Reduced energy consumption, less thermal stress on heat-sensitive substrates (thin MDF, certain plastics), potentially longer glue pot life, reduced smoke/odor.

Medium-Temperature Adhesives

The “sweet spot” for most standard applications. Excellent balance of viscosity, open time, and bond strength for common PVC edge banding and substrates (MDF, particleboard).

High-Temperature Adhesives

Highest bond strength potential, faster setting times for ultra-high-speed lines, excellent gap-filling on uneven surfaces.

Matching temperature to your specific machine model, tape, and substrate is crucial. Our technical datasheets provide precise recommendations.

We believe in face-to-face interaction

From high-end kitchen manufacturers in Germany to mass office furniture producers in the United States, to emerging factories in Southeast Asia, Luyao Glue is the trusted adhesive behind high-quality furniture around the world. We proudly display our customers.

Ready for a Superior Bond?

Get Your Tailored Luyao Quote

Optimizing your PVC edge banding glue is a direct path to higher quality and efficiency. Provide the details below, and our team will deliver a competitive quote promptly:

- Glue Type Required: EVA (Filled/Unfilled) / PUR / Specific Luyao Product Code?

- Color: Natural/Clear, Brown, Black, White, Grey?

- Required Quantity: Estimated monthly/annual usage (kg or tons)?

- Packaging Preference: 25kg Bags, 750kg Pallets, Cartridges (Specify Machine Brand/Model: e.g., Homag, IMA, SCM, Brandt, Biesse)?

- Destination Country/Port: For accurate shipping costs.

- Your Edge Banding Machine Brand/Model: Essential for compatibility and performance advice.

- Primary Tape Material: PVC, ABS, Melamine, Acrylic, Wood Veneer? (Specific type if known)

- Primary Substrate: MDF, Particleboard, Plywood, Solid Wood?

- Key Application Requirements: Speed, moisture/heat resistance needs, special challenges?

Shanghai Luyao Industry Co.ltd

Why Shanghai Luyao is Your Strategic Glue Partner

- Consistency You Can Build On: Rigorous QC and advanced manufacturing ensure batch-to-batch uniformity. Your edge banding machine settings stay constant, minimizing rejects and maximizing uptime. Our tolerance levels are 30% tighter than industry averages.

- Solutions, Not Just Product: We offer comprehensive technical support. From machine compatibility checks to troubleshooting bond issues or optimizing settings for new materials, our engineers are your partners. Average problem resolution time: < 24 hours.

- Global Reach, Local Responsiveness: Serving clients across Europe, North America, Southeast Asia, and the Middle East. Dedicated multilingual account managers ensure clear communication and timely support, regardless of your timezone.

- Responsive & Scalable Supply Chain: Robust raw material sourcing and significant production capacity mean reliable supply, even during peak demand. Flexible packaging (25kg bags, 750kg pallets, cartridges for Holz-Her, Brandt, etc.).

- Commitment to Innovation: 8% of revenue reinvested annually in R&D. We pioneer developments in bio-based polymers, low-temp performance, and enhanced sustainability profiles.

- Proven Performance: Trusted by over 500 furniture manufacturers globally, contributing to the production of millions of pieces annually. Our glues are field-tested in diverse climates and demanding applications.

Contact us today

Partner with Shanghai Luyao Industry Co., Ltd. Transform your edge banding from a necessary step to a strategic advantage. Experience the precision, performance, and partnership that only a dedicated adhesive expert can provide. Contact us today and bond with confidence.