Shanghai Luyao Industry Co., Ltd

Professional Melamine Edge Banding Supplier

For B2B buyers, partnering with Luyao means stable supply, cost competitiveness, and one-stop service that solves core procurement pain points.

Melamine Edge Banding Supplier

Shanghai Luyao Industry Co.Ltd was established in 2002 and is situated in Shanghai with its production factory located in Taizhou Jiangsu Province. Operating under the brand “Luyao” has been deeply rooted in the furniture and building materials industry for more than 20 years covering edge banding PVC film hot melt glue PVC screw cover sticker and one-stop whole-house customization services. It is a comprehensive group company integrating R&D design production sales and full-chain services. In addition Luyao has obtained a series of authoritative certifications including CE FSC CARB EPA and ISO 9001 ensuring product quality and compliance.

The “Luyao” group owns 35 direct branches and over 1300 warehouse distribution outlets across more than 20 provinces in China with products exported to clients in North America Europe Asia and other major global regions. At present the company has invested in Zhejiang Jiangsu and Shandong provinces to build large-scale production bases including an edge banding production base with an annual output of 1.5 million square meters an EVA and PUR hot melt glue production base with an annual output of 6 hundred thousand square meters a PVC film production base with an annual output of 7 hundred thousand square meters and a screw cover sticker workshop with a comprehensive area exceeding 7 hundred thousand square meters.

Luyao has always adhered to the concepts of “environmental friendly” “Integrity First” and the strategy of sustainable development. It sincerely looks forward to providing the most comprehensive professional services and high-quality products for business customers around the world.We are glad to work together with you and finally bring you the satisfied products.

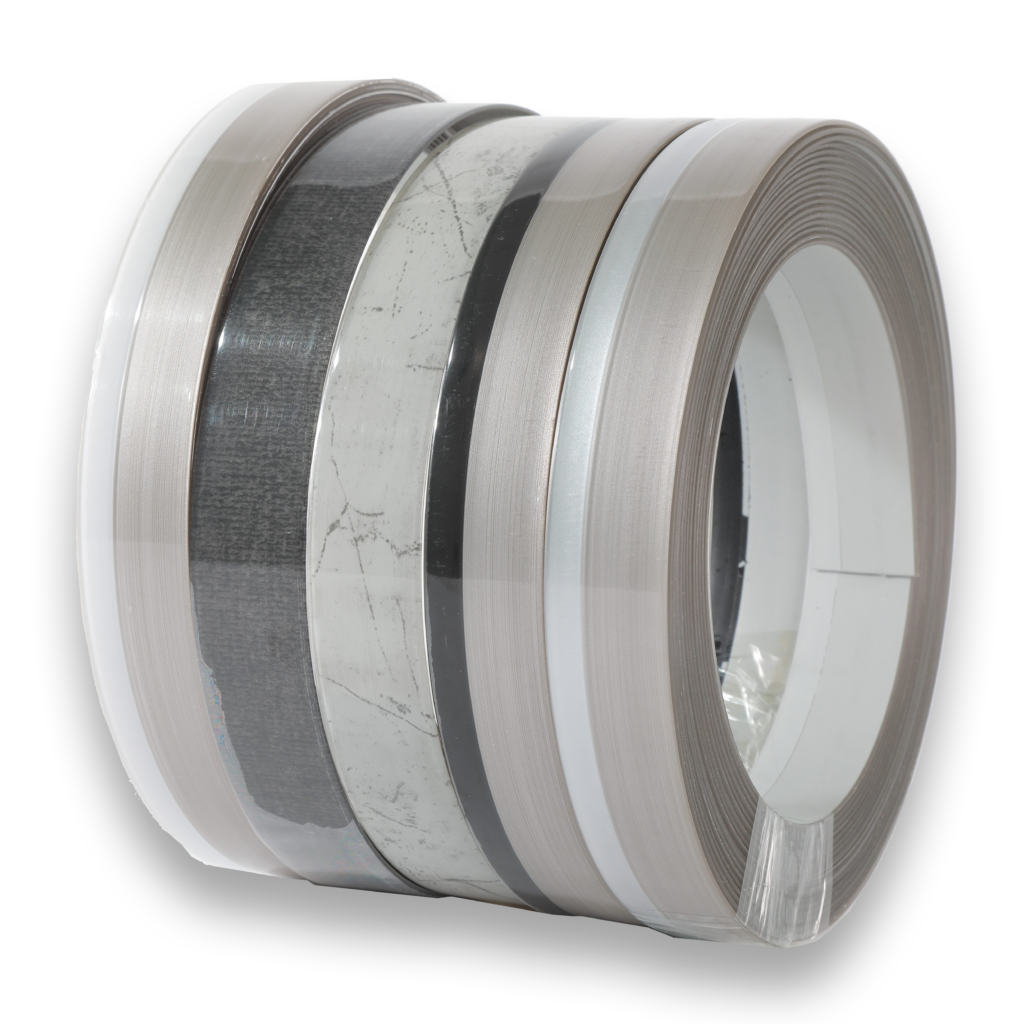

Melamine Edge Banding for Diverse Needs

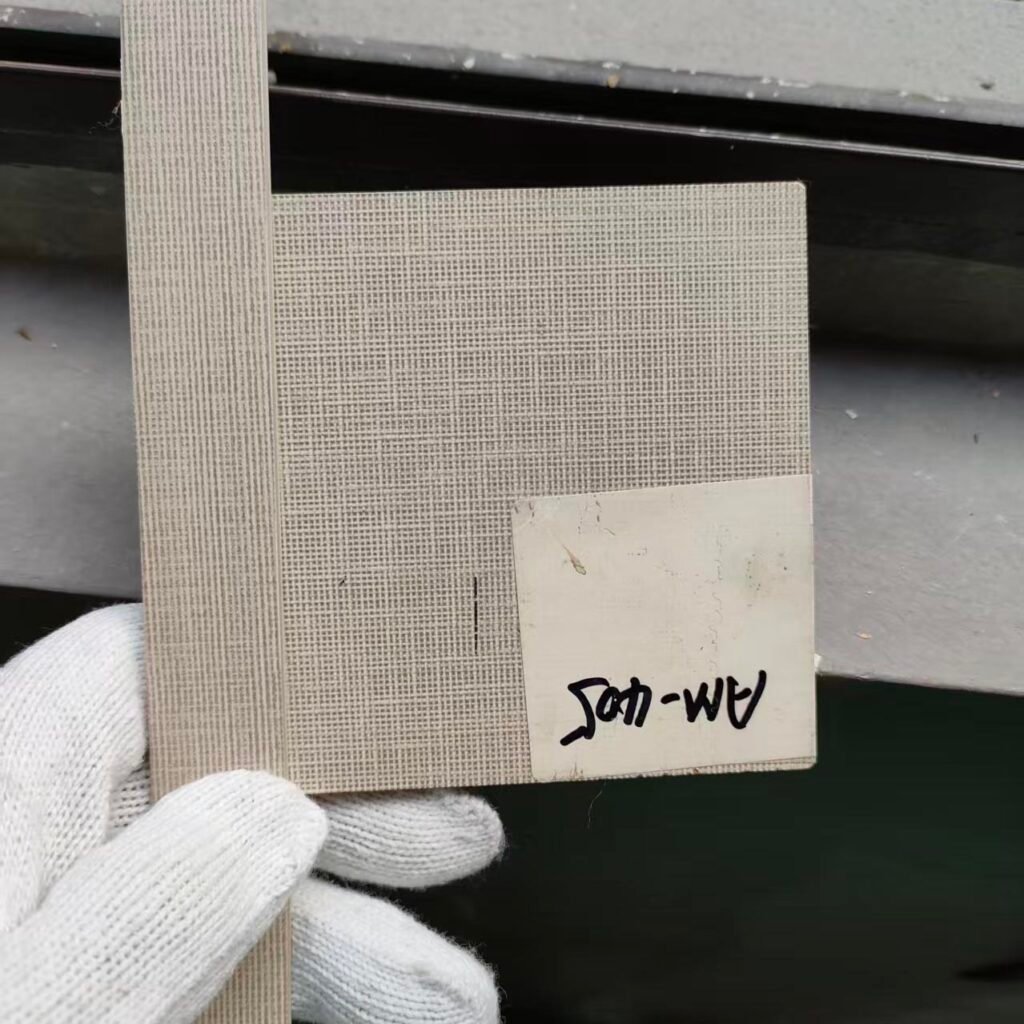

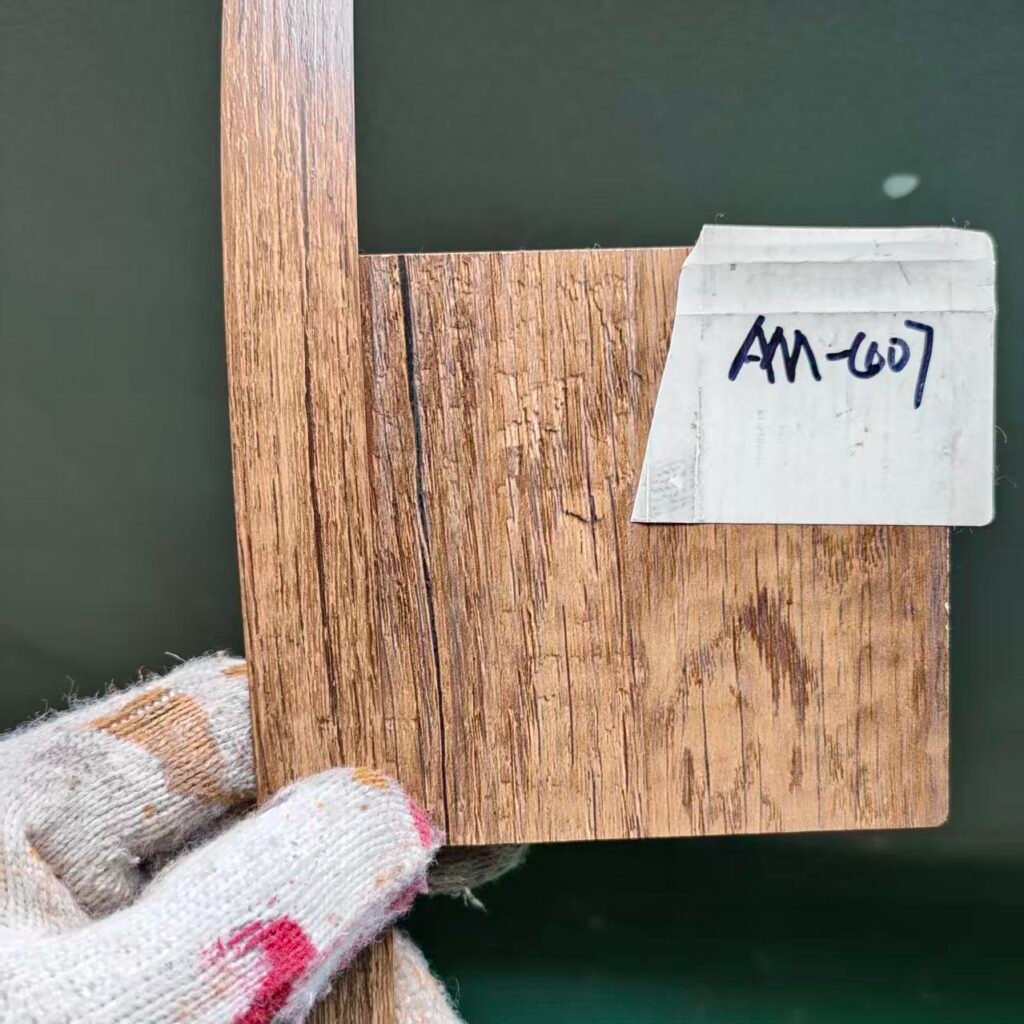

Our standard melamine edge banding is designed for mass production needs, with stable specifications and consistent quality to meet the basic requirements of mainstream furniture and cabinetry production. Available in thicknesses from 0.4mm to 3.0mm, widths from 10mm to 60mm, and roll lengths of 100m, 500m or 1000m, it perfectly fits different panel sizes and processing scenarios.

The surface offers three finish options: matte, glossy, and textured (wood grain/stone grain). The 1000+ standard color shades are carefully calibrated to match mainstream melamine panels, ensuring color consistency between edge banding and panels, and reducing post-processing adjustments for customers.

Customized Melamine Edge Banding Solutions

For regional market differences, we offer special specification models: curved application versions for curved furniture processing, fire-retardant models for commercial space projects, and anti-yellowing models for high-light environment applications. In addition, we provide EVA, PUR, and hot-melt adhesive matching options, tailoring the adhesive type to customers’ production processes and usage environments to ensure firm bonding.

Other edgebanding tape

Factory Capacity That Supports Stable Cooperation

Luyao owns a 100,000㎡+ production base, equipped with advanced melamine lamination and extrusion lines. The automated production equipment not only improves production efficiency but also ensures consistent product quality across batches. With a monthly output of over 300,000 meters, we can flexibly respond to different order volumes—whether it’s small-batch trial orders (starting from 5000 meters per color) or large-batch bulk orders, we can guarantee on-time delivery.

Our R&D team has over 15 years of industry experience, and the in-house lab is committed to product optimization and new formula development. We establish a strict 5-step inspection process: raw material screening (selecting high-quality base paper and melamine resin), lamination quality check (ensuring uniform film adhesion), adhesive strength test (testing bonding firmness), surface finish inspection (controlling color difference and flatness), and final packaging verification (preventing damage during transportation)

We hold REACH, RoHS, and ISO 9001 certifications, and provide a 1-year warranty for non-human damage. To solve the industry-wide color difference problem, we adopt professional spectrophotometers (ΔE precision ≤0.02) and establish a three-level color board system (master color board, production color board, batch retention sample), realizing controllable, replicable, and traceable color management.

Your Trusted Long-Term Partner for Melamine Edge Banding

Whether you need standard products, customized solutions, or have special requirements for delivery and after-sales service, Luyao is ready to serve you. Contact us now to get customized quotes, free samples, and professional technical consultation, and start a win-win cooperation journey!