Understanding Industrial Hot Glue

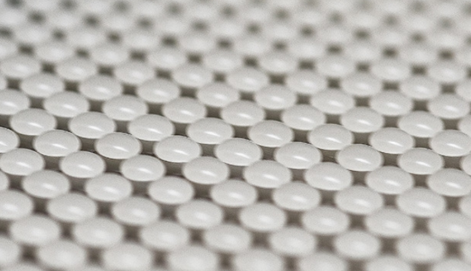

Industrial hot glue, also known as hot melt adhesives, are a versatile and highly effective bonding solution used in a variety of applications including packaging, labeling, construction, woodworking and non-woven hygiene products. Shanghai Luyao Industrial Co., Ltd. specializes in providing high-quality hot melt adhesives to meet the specific needs of our customers.

What is hot melt adhesive made of?

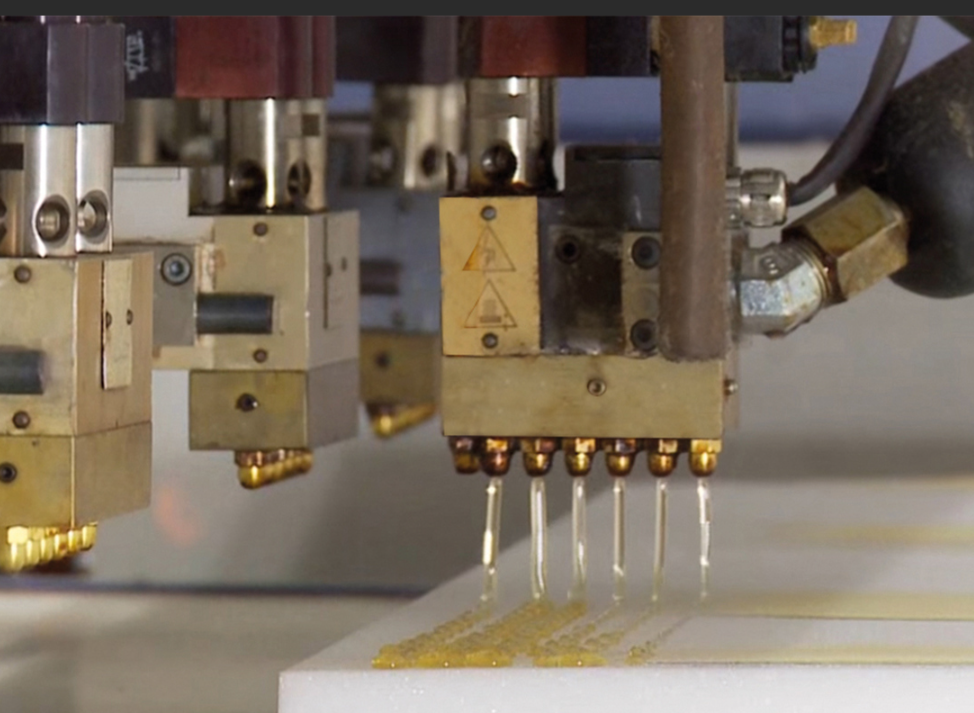

When choosing an adhesive technology, it is critical to understand the ingredients of hot melt adhesives. Hot melt adhesives are popular for their advanced polymer formulations that can be customized for different applications. They are 100% solid thermoplastics that are applied in a molten state and form a strong bond after cooling. This rapid curing process distinguishes hot melt adhesives from solvent-based adhesives, which require drying time and are cumbersome to manage in a production environment.

Ingredients of Hot Melt Adhesives

Hot melt adhesives typically contain five main ingredients: polymers, plasticizers, resins, waxes/oils, and antioxidants. Each ingredient plays a critical role in the performance of the adhesive and must be compatible for optimal results.

1.Polymers

Polymers are the backbone of hot melt adhesive formulations, providing the necessary strength and flexibility. Commonly used polymers include:

- Ethylene vinyl acetate (EVA): EVA is known for its versatility and compatibility with a wide range of waxes and oils, making it a popular choice for many applications.

- Thermoplastic rubber (TPR): It has excellent elasticity and is ideal for applications that require flexibility.

- Metallocene polyolefin (MPO): This polymer is designed for advanced bonding applications and provides improved precision, mileage, and temperature performance.

- Amorphous polyalphaolefin (APAO): APAO is known for its high clarity and low odor and is often used in sensitive applications.

Increasing the strength of the polymer in a formulation enhances its viscosity and flexibility while also improving heat and chemical resistance.

2.Resins

Resins give hot melt adhesives their tack, allowing them to form an initial bond between substrates. Key properties affected by resins include:

- Softening point: Resins have a softening point above room temperature, allowing for a strong bond even under varying conditions.

- Stability: The type and amount of resin used can affect the glue’s stability, color, odor, and heat resistance.

Tackifying resins are critical to ensuring that the glue maintains its properties over long periods of time, especially when subjected to pressure or temperature fluctuations.

3.Plasticizers

Plasticizers are added to enhance the flexibility and processability of hot melt adhesives. They act as a second base polymer, compensating for resins that may be too rigid. Benefits of plasticizers include:

- Improved wetting: This enhances the ability of the glue to spread and effectively bond to substrates.

- Reduced melt viscosity: Lower viscosity makes application easier, especially in high-speed production environments.

4.Waxes/Oils

Various types of waxes and oils, including paraffin and synthetic options, enhance hot melt formulations by controlling specific properties:

- Open time: The time it takes for the glue to form a bond after application.

- Cure speed: The speed at which a bond of acceptable strength is achieved.

Waxes and oils also affect the heat resistance and viscosity of the adhesive, allowing manufacturers to tailor the glue to specific production requirements.

5.Antioxidants

Antioxidants prevent hot melt adhesives from degrading during storage and application, especially at elevated temperatures. While they do not directly affect the performance of the adhesive, they are essential to maintaining the long-term effectiveness of the glue.

Other additives

Other additives, such as fillers, UV stabilizers, pigments, dyes, and stabilizers, enhance hot melt formulations by fine-tuning specific properties. For example:

- Fillers: change viscosity and enhance certain physical properties.

- UV stabilizers: prevent degradation from light.

- Pigments and dyes: allow for color customization, making the adhesive suitable for a variety of aesthetic requirements.

Advantages of Industrial Hot Melt Adhesives

Hot melt adhesives offer several advantages over traditional adhesive technologies:

- Fast cure: Hot melt adhesives cure quickly upon cooling, significantly reducing production time.

- No drying area required: Unlike solvent-based adhesives, hot melt adhesives do not require drying space, saving valuable floor space in production facilities.

- Environmentally friendly: Hot melt adhesives typically contain fewer volatile organic compounds (VOCs), making them a safer choice for workers and the environment.

- Versatile: The ability to customize formulations means hot melt adhesives can be used for a variety of applications, from packaging to woodworking.

Applications of Hot Melt Adhesives

Industrial hot melt adhesives are versatile and suitable for a variety of applications:

- Packaging: Ideal for creating durable seals and bonds in packaging materials.

- Woodworking: Used for edgebanding, laminating, and assembling furniture components.

- Labels: Provide strong adhesion for labels on a variety of surfaces.

- Construction: Effectively bond materials in building projects to ensure structural integrity.

Conclusion

At Shanghai Luyao Industrial Co., Ltd., we are committed to providing high-quality industrial hot glue solutions to meet the diverse needs of our customers. Understanding the composition and benefits of hot melt adhesives allows businesses to make informed decisions for their specific applications. For more information or to inquire about our products, please contact us at emily.gu@asiaedgebanding.com or call +86-15618525178. Let us help you achieve the best results for your project with our superior hot melt adhesive solutions!

Leave a Reply