Wholesale price edge banding Factory

Premium 3D Acrylic Edge Banding Strips

Shanghai Luyao Industries: Your trusted manufacturer of high-gloss, durable, and eco-friendly edge solutions. Customized Sizes • Global Standard Request

Why choose 3D acrylic edge banding?

Advantages of acrylic edge banding

- Ultra-realistic 3D visual effect: The high-transmittance acrylic layer simulates the three-dimensional texture of natural stone/wood grain to enhance the high-end texture of furniture

- Excellent durability: scratch-resistant, anti-yellowing, solvent-resistant, suitable for high-frequency use scenarios such as kitchens and bathrooms

- Environmental compliance: REACH, OEKO-TEX® certification, no heavy metal/formaldehyde release

- Hot bending adaptability: The flexible substrate supports curved edge banding and fits seamlessly to the edges of special-shaped furniture

- Easy to clean and maintain: The high-density surface is stain-resistant, and it can be wiped clean

Technical Specifications & Visual Showcase

| Series | Thickness | Width Range | Surface Finish | Compatible Substrates |

|---|---|---|---|---|

| Gloss Pro | 0.8–1.2 mm | 18–45 mm | Mirror High-Gloss | MDF, Particleboard |

| Matte Luxe | 1.0–1.5 mm | 22–50 mm | Soft-Touch Satin | Solid Wood, Plywood |

| 3D Vein | 1.2 mm | 15–60 mm | Embossed Marble/Wood | Premium Custom Furniture |

sHANGAH lUYAO INDUSTRY CO.LTD

20 years of experience in edge banding · The monthly production capacity is 2 million meters

Detailed explanation of the edge banding

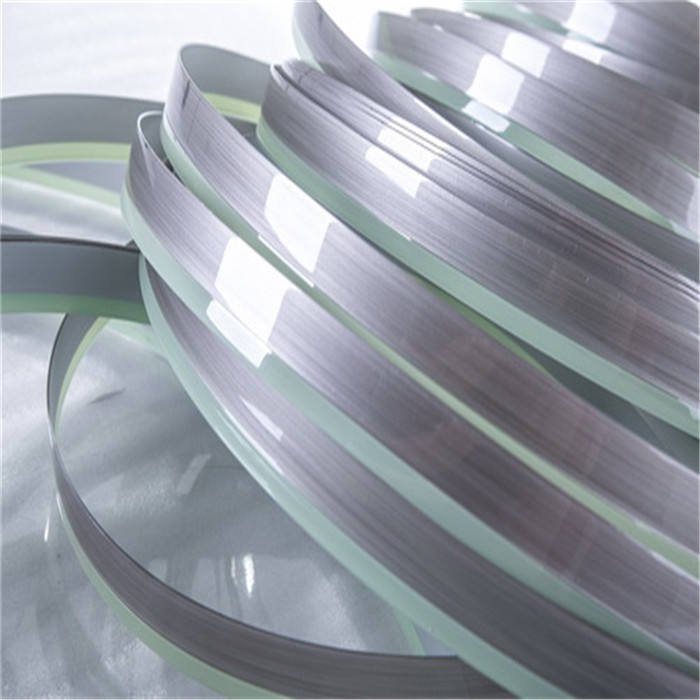

The surface of Lu Yao’s 3D acrylic edging provides a mirror-grade high-gloss effect and has anti-fingerprint properties to keep the surface clean for a long time. The middle layer accurately reproduces the 3D three-dimensional texture of natural stone/wood grain through digital printing technology to achieve a millimeter-level depth of field effect; The base material is made of modified PMMA plastic.

The adhesive layer is pre-coated with a high-performance EVA hot melt adhesive (adhesive strength ≥ 3.5N/mm²) and permanently bonds to the substrate in just 3 seconds at 130°C. This technological breakthrough significantly improves the efficiency of the furniture production line, reduces the processing time by 60% compared to traditional edging, and passes 10,000 hot and cold cycles without degumming.

The edge banding solution is designed for harsh environments: medical furniture is chemically resistant to EN ISO 10993, has been tested for 72 hours in salt spray, and has been able to withstand 200,000 frictions on the surface of a retail display. It has become the preferred edge banding solution for high-end cabinets, luxury yacht cabins and display systems in brand flagship stores.

Shanghai Luyao Industry co.ltd

edge banding Manufacturer

Shanghai Luyao Industry Co., Ltd. has pioneered advanced surface solutions since 2002, evolving into a globally trusted manufacturer of precision-engineered edge banding, PVC films, kitchen skirting boards, and specialty hot melt adhesives. Our cross-continental impact spans 100+ nations—from Canada’s architectural woodworking sector to Australia’s custom cabinetry market, Russia’s commercial furniture hubs, Spain’s luxury interiors, and the UAE’s high-rise developments. Dual ISO-certified manufacturing hubs in strategic industrial zones demonstrate our commitment to supply chain resilience and technological agility, enabling tailored responses to regional material specifications and sustainability mandates.

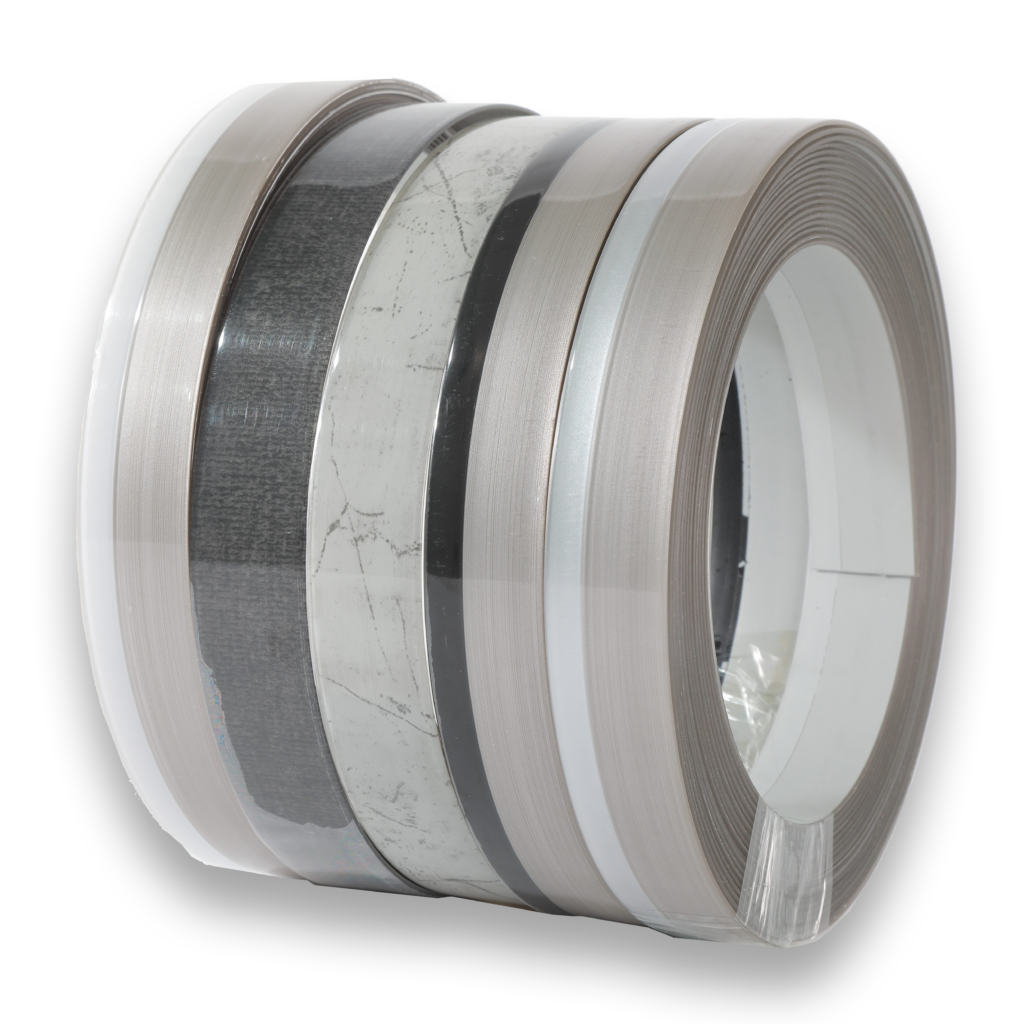

3d acrylic edge banding strips

Production process

Our production begins with a rigorous inspection of PMMA pellets, followed by automated co-extrusion, fusing a three-layer structure under precisely controlled heat and pressure. Then, advanced laser engraving embossing technology imparts a realistic 3D texture to enhance scratch resistance before the material undergoes 10 stages of UV curing and polishing. A computer-guided optical measuring system ensures dimensional accuracy (± 0.05 mm thickness tolerance) during the slitting process, and each production batch is verified by a 48-hour accelerated weathering test that simulates extreme temperature, humidity and UV exposure – all documented in our ISO 9001:2015 certified quality management system

Fast track for inquiry

Frequently Asked Questions about Purchases

Related Products

Customized service

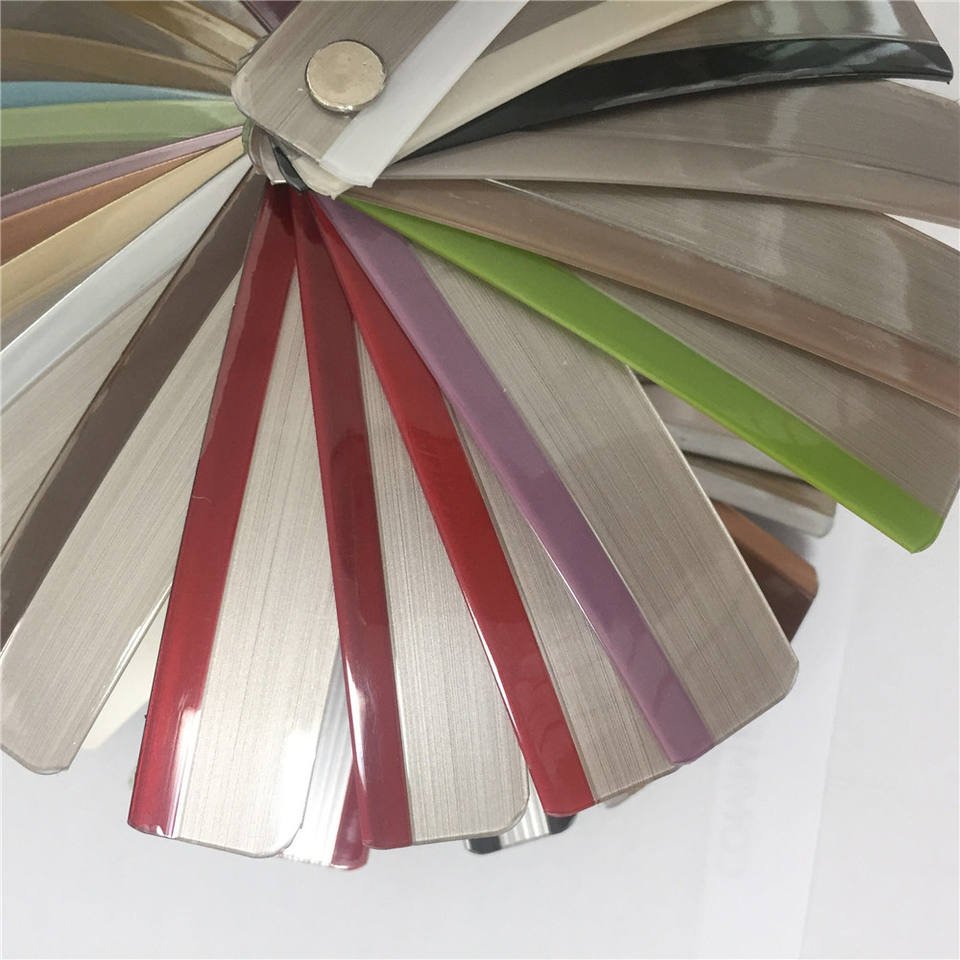

Color: Colour chart match | Textures: Provides an as-is replica

Size: width 15-90mm | Thickness 0.3-4.0mm

Packing: Single roll length/anti-static film/carton/logo

Adhesive backing: Adjust melt flow index (suitable for high/low temperature environments)

Proofing 7 days · 15-25 days for mass production