EVA and PUR Hot Melt Adhesive Solutions from Shanghai Luyao Industrial Co., Ltd

Edge banding adhesive

In the furniture manufacturing and interior decoration industries, edge banding is far more than just aesthetic decoration; it directly determines the product’s durability, moisture resistance, environmental performance, and overall quality. A perfect, strong edge banding effectively isolates moisture, strengthens the board structure, and enhances the furniture’s texture. The key to achieving this lies in the superior performance of the edge banding adhesive.

Edge Banding Adhesive

As a leading enterprise in the edge banding materials field, Shanghai Luyao Industrial Co., Ltd., with 18 years of professional experience, deeply understands the diverse needs for edge banding adhesives in different production environments. This article will comprehensively analyze the technical characteristics, advantages, and practical applications of two mainstream hot melt adhesives: EVA and PUR, providing industry professionals with scientific selection criteria and process optimization solutions.

Hot Melt Adhesive Classification

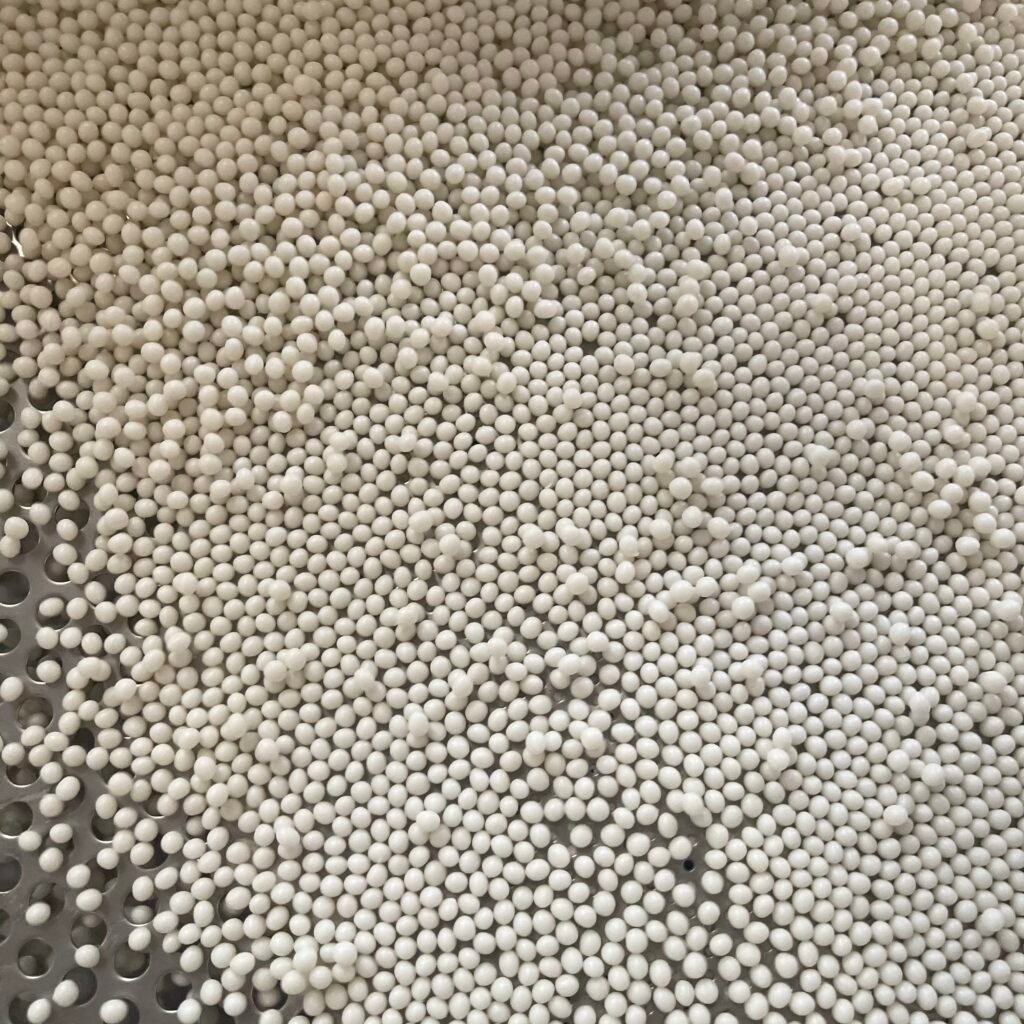

EVA hot melt glue

PUR hot melt glue

EVA Hot Melt Adhesive

Since its introduction, EVA (ethylene-vinyl acetate copolymer) hot melt adhesive has become the most widely used adhesive type in the furniture edge banding industry due to its balanced performance and ease of use. EVA hot melt adhesive is essentially a thermoplastic polymer, solid at room temperature, turning into a liquid upon heating to a molten state, and solidifying upon cooling to form a bond.

Physical State Change:

The bonding process of EVA hot melt adhesive relies entirely on physical state changes and does not involve chemical reactions. This means it is reversible, meaning the adhesive layer can be reheated and melted. This characteristic brings ease of operation but also limits its final performance.

Wide Operating Window:

The typical operating temperature range of EVA hot melt adhesive is 160-210°C, making it suitable for equipment with varying levels of automation, from fully automatic high-speed edge banding machines to manual equipment.

Wide Material Compatibility:

It exhibits good adhesion to various edge banding materials such as PVC, ABS, acrylic, wood veneer, and decorative paper, as well as substrates such as particleboard and medium-density fiberboard.

Technical Advantages

Raw Material Selection and Batch Stability: We insist on using imported high-quality EVA resin as the base material, ensuring consistent melting point, viscosity, and open time across different batches, providing a stable and reliable process foundation for our customers’ production lines.

Optimized Bond Strength:

Through molecular structure design and optimized additive ratios, our EVA hot melt adhesive forms strong cohesion and adhesion after curing, achieving a bond strength of ≥12MPa, meeting the needs of most furniture manufacturing.

Excellent Environmental Performance:

Our products are free of solvents, formaldehyde, and other harmful substances, complying with environmental standards such as GB/T 18583-2008, RoHS, and REACH, ensuring the creation of green furniture products for our customers.

Significant Cost-Effectiveness:

While maintaining performance, rheological optimization achieves a lower application rate (150-220g/m²), effectively controlling production costs for our customers.

PUR Hot Melt Adhesive

PUR (Reactive Polyurethane) hot melt adhesive represents the latest advancement in edge sealing technology. Its core advantage stems from its unique chemical curing mechanism. Unlike the physical curing of EVA, PUR adhesive, after being heated and melted for application, undergoes an irreversible chemical reaction with moisture in the air, forming a cross-linked three-dimensional network structure.

Performance Breakthrough:

Double Bond Strength:

The final bond strength of PUR hot melt adhesive can reach more than 3.2 times that of EVA products, forming a near-permanent bonding effect.

Excellent Environmental Resistance:

The cured PUR adhesive layer can withstand a temperature range of -40°C to 150°C and is completely unaffected by humidity.

Creep Resistance:

It can withstand a load of 18 kg/cm² without creep failure, far superior to the 6-hour failure point of EVA adhesive.

Technological Innovation

Formula Serialization: Dedicated formulas have been developed for different application scenarios. For example, the LX-7F high-flexibility formula is suitable for marine environments, the PH-88 chemical-resistant formula is suitable for medical facilities, and the T-200 impact-resistant formula meets the high-strength requirements of office furniture.

Process Parameter Optimization:

Through the transformation and practice of 47 production lines, the optimal process window has been summarized: melt temperature 115-130°C, application pressure 0.15-0.3 MPa, and nozzle gap 0.2mm±0.05mm.

Curing Environment Control:

An accelerated curing environment with a relative humidity of 40-70% has been established, combined with a post-pressure time of at least 90 seconds to ensure sufficient reaction.

Full-Process Testing:

A peel strength testing system of 2 hours/24 hours/72 hours has been established, combined with thermal shock testing (-30°C to 80°C cycle) to verify product reliability.

Contact Shanghai Luyao Industrial Co., Ltd.

Welcome to contact Shanghai Luyao Industrial Co., Ltd. for customized edge banding solutions!

aBOUT LUYAO

Shanghai luyao industry co.ltd’s main products, PVC edge banding tape and hot melt adhesive, are key materials used in furniture manufacturing for sealing the edges of panels.

Superior Physical Properties: Its edge banding tape products feature high hardness (Shore hardness D 79±4), good abrasion resistance and fracture resistance, ensuring durability.

Excellent Colorfastness: The edge banding tape is manufactured according to EN ISO 4892-2 lightfastness standards, resisting fading even with methyl ethyl ketone (MEK) wiping, maintaining a vibrant appearance for a long time.

Superior Manufacturing Process: Utilizing a homogeneous inner and outer layer structure ensures no unsightly white edges after trimming, while the clear adhesive lines allow for a strong bond with the panel using hot melt adhesive.

Shanghai Luyao Industrial Co., Ltd. is a highly internationalized enterprise with an annual inventory exceeding 25 million meters. Its products cover global markets, including Canada, Australia, Russia, Spain, and the UAE.

Factory production demonstration