furniture edge banding tape

The smooth edges of a kitchen cabinet, the seamless grain match on a walnut bookcase, the scratch-resistant finish on a child’s desk—these small elements combine to create a look of craftsmanship and longevity. But all too often, furniture falls short of this standard because of one overlooked component: edge banding tape. Peeling edges, faded colors, and weak adhesion can turn a beautiful piece into an eyesore in months. That’s where our premium furniture edge banding tape comes in. Engineered for the demands of daily use and designed to complement any furniture style, it’s the secret to furniture that looks better and lasts longer.

Why Settle for Inferior Edge Banding?

The Cost of Cutting Corners

Most low-quality options use weak adhesives that melt or degrade under heat, moisture, or even light use. They’re made from thin, toxic materials that scratch easily, stain permanently, and fade within months. For furniture manufacturers, this means high return rates, angry customers, and a damaged reputation.

Luyao products are designed to solve every common pain point associated with cheap alternatives. Whether you need something that can handle the steam of a kitchen, the wear of an office desk, or the mess of a child’s room, we have a solution that doesn’t just perform— it enhances the look of your furniture.

Why Choose Our Furniture Edge Banding Tape?

4 Unbeatable Advantages

1. Superior Adhesion: Zero Peeling, Even in the Toughest Environments

Adhesion is the backbone of any good edge banding tape. If the tape doesn’t stick—and stay stuck—nothing else matters. That’s why we’ve invested heavily in developing a high-temperature resistant hot-melt glue that’s engineered for maximum bond strength. Unlike cheap adhesives that fail at the first sign of heat or moisture, our glue can withstand 180℃ continuous heating—far more than the average kitchen or office environment will ever throw at it.

But don’t just take our word for it. Our edge banding tape has passed rigorous industrial peeling tests, achieving a bonding strength of ≥3.5N/mm. To put that in perspective, that’s strong enough to resist the constant opening and closing of cabinet doors, the weight of heavy objects on desk edges, and even the humidity of a bathroom or laundry room. We’ve tested it in real-world scenarios too: in high-humidity kitchen environments, our tape maintains a tight bond for 5+ years with zero peeling. For furniture manufacturers, that translates to fewer returns and happier customers. For homeowners, it means furniture that looks new for years.

Our adhesive works seamlessly with all common furniture materials, including solid wood, MDF, particleboard, and plywood. No more worrying about compatibility—our tape sticks to whatever surface you’re working with, creating a seamless bond that’s almost impossible to distinguish from the furniture itself.

2. Durable & Wear-Resistant: Scratch-Proof, Stain-Proof, and Built to Last

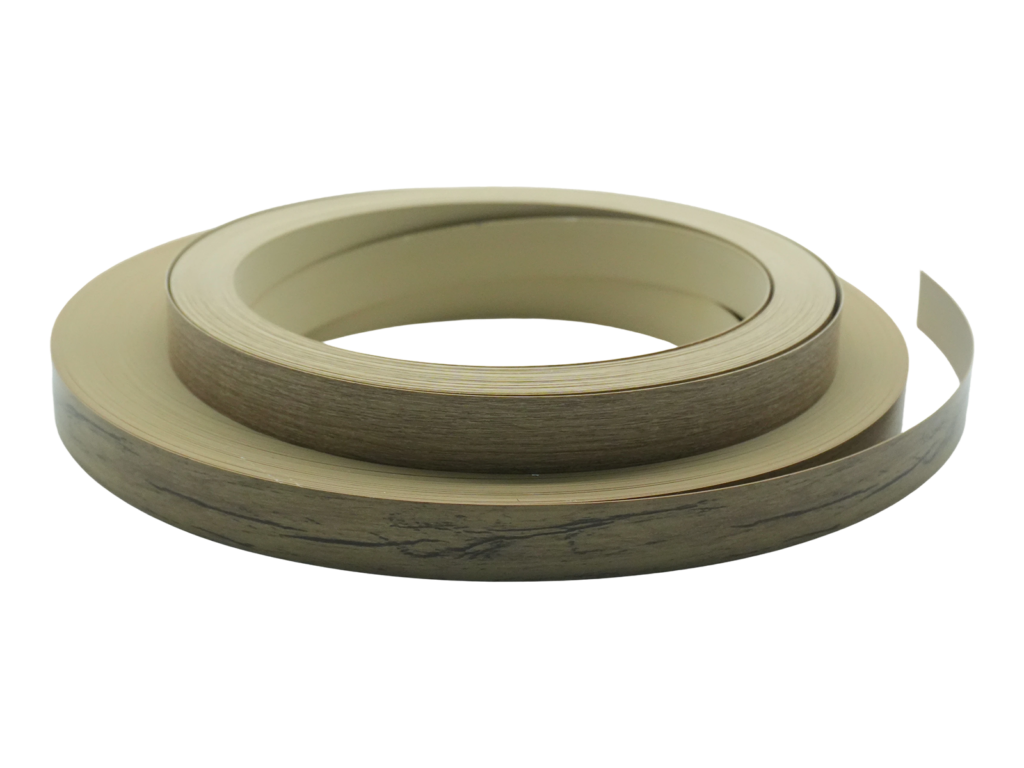

Furniture edges take a beating. They get scraped by keys, bumped by chairs, spilled on by coffee or oil, and marked by pens or markers. Cheap edge banding gives up quickly under this abuse, but ours is built to resist it all. We use only the highest-quality materials—food-grade PVC, impact-resistant ABS, and high-density melamine—each chosen for its unique durability properties.

Let’s start with the numbers. Our PVC edge banding tape undergoes the Martindale abrasion test, a global standard for measuring wear resistance, and achieves ≥5000 wear cycles. That’s far more than the industry average, meaning it can handle years of daily use without showing signs of wear. It’s also incredibly hard—with a hardness rating of ≥65 Shore D—so it resists scratches from sharp objects like knives, scissors, or pet claws. For parents, that means no more panic when the kids drag toys across the dining table. For office managers, it means desks that stay looking professional even with heavy use.

Stains are another common problem, but our edge banding tape repels them like a shield. It resists common household and commercial stains, including coffee, oil, ink, wine, and sauce. And if a spill does happen? Our tape has a stain removal rate of up to 98%. A quick wipe with a damp cloth is all it takes to return it to its original condition—no harsh chemicals, no permanent marks, no hassle.

We also prioritize safety. Our food-grade PVC is non-toxic, making it perfect for kitchen cabinets, children’s furniture, and even restaurant tables. It meets strict EU REACH and US CARB Phase 2 standards, so you can feel confident using it in any space—whether it’s a home, a school, or a hospital.

3. Customizable Styles: Match Any Design Vision

Furniture is about style as much as function. A beautiful piece can be ruined by edge banding that doesn’t match the wood grain, color, or texture of the main surface. That’s why we offer an extensive range of customizable options—so you can get edge banding that complements your furniture, not clashes with it.

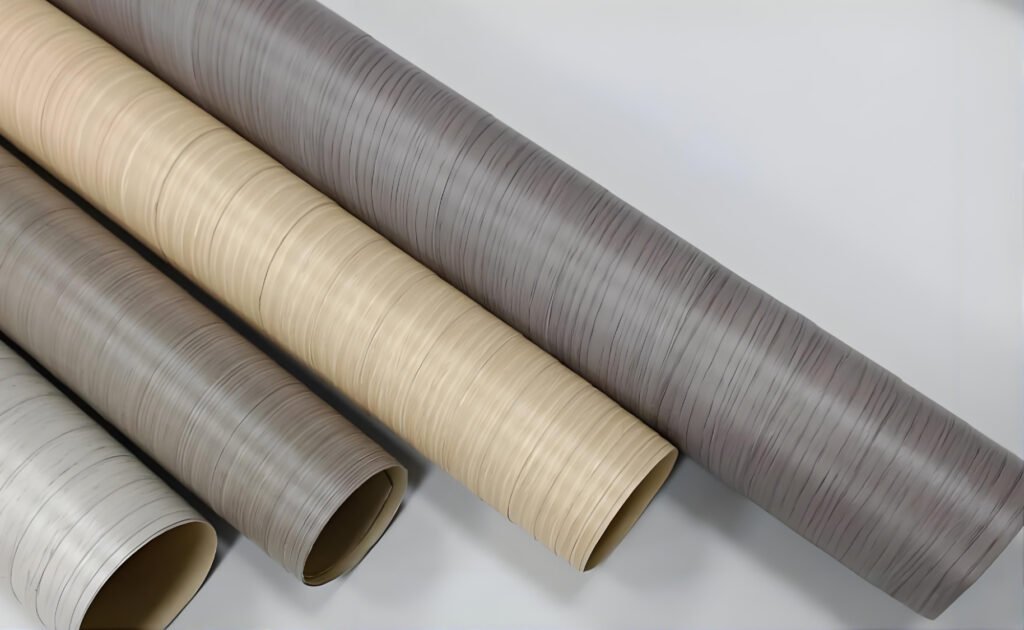

Let’s start with colors and textures. We offer 86 color options in total, including 42 realistic wood grain textures that perfectly match popular woods like oak, walnut, maple, cherry, and teak. Our wood grain prints are so detailed that even close up, it’s hard to tell the edge banding from the real wood. For modern or minimalist designs, we also offer solid colors, marble textures, and matte or glossy finishes. Whether you’re making a rustic oak bookshelf, a sleek black office desk, or a marble-inspired kitchen cabinet, we have a color and texture that fits.

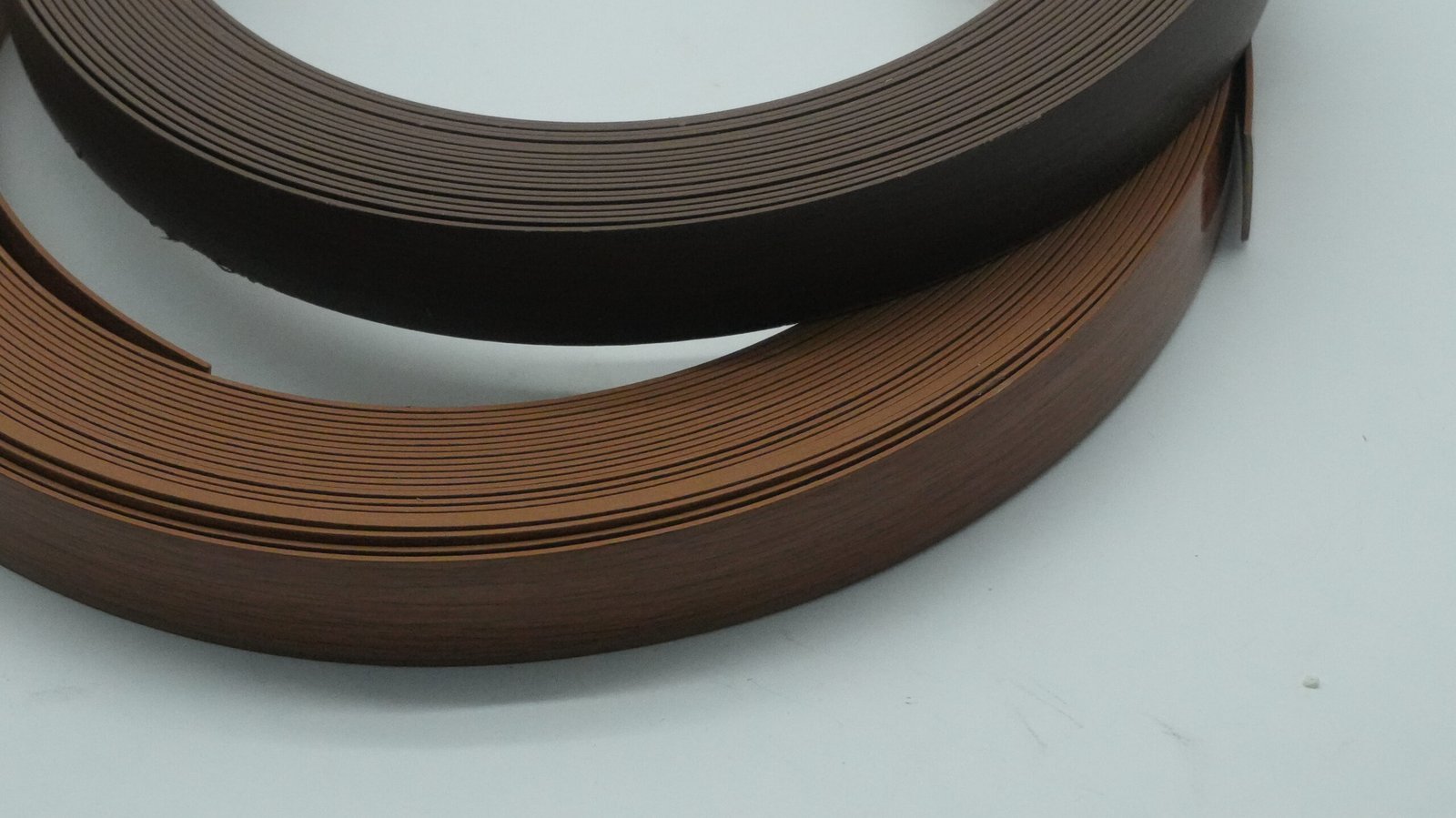

Width is another key customization factor. We offer 12 standard widths, ranging from 10mm to 50mm, with a precision of ±0.1mm—so you get a perfect fit every time. But we don’t stop at standard sizes. We also support custom widths from 8mm to 60mm, so you can get exactly what you need for your specific project. Need a unique pattern or logo printed on the edge banding? We do that too. Whether you’re a furniture brand looking to add your logo to custom pieces or a business wanting branded office furniture, our custom printing service has you covered.

We understand that customization can be a concern for small orders, but we’ve made it accessible. Our minimum custom order quantity is just 500 rolls, and we offer 7-day sample delivery—so you can test the color, texture, and fit before placing a full order. No more guessing or settling for second-best—get exactly what you want, when you want it.

4. Easy to Apply: Save Time, Labor, and Money

Whether you’re a large furniture factory with automated machinery or a DIYer working from home, our edge banding tape is designed to be easy to apply. We’ve streamlined the process with a pre-glued design that reduces application steps by 40% compared to traditional tape. That means less time spent on each piece, lower labor costs, and faster project completion.

For professional manufacturers, our tape is fully compatible with automatic edge banding machines, which can apply the tape at a production efficiency of up to 30 meters per minute. That’s a game-changer for high-volume orders—you can increase output without sacrificing quality. For smaller workshops or DIYers, we offer two simple manual options: hot air guns (with an optimal temperature range of 160-180℃) or even household irons. No fancy equipment needed—just a few basic tools and a little know-how.

The pre-glued design also means less waste. Traditional edge banding often requires separate glue application, which can lead to uneven coverage, mess, and wasted materials. Our tape has a consistent layer of hot-melt glue that melts evenly and bonds quickly, so you get a perfect application every time. For factories, this translates to a 15% annual reduction in labor costs—money that can be reinvested in other areas of your business.

Furniture Edge Banding Tape Color

From a Focus on Quality to a Vision for Innovation

Most Chinese edge banding tape manufacturers in the 2002s prioritized quantity over quality, leaving global furniture makers with two bad options—overpriced European tape or cheap, unreliable Chinese tape.

By 2015, our annual production capacity had grown to 28 million meters, and we expanded our factory to 12,000 square meters in Shanghai’s jiading Industrial Park—strategically located near the Port of Shanghai for fast, cost-effective global shipping.

A great product starts with great production. At Shanghai Luyao, we’ve built a manufacturing ecosystem that balances cutting-edge technology with rigorous human oversight. Here’s a behind-the-scenes look at how we make our furniture edge banding tape:

- Raw Material Sourcing: The Foundation of Durability

We believe that “quality begins at the source.” That’s why we only work with 5 carefully vetted suppliers for our core materials—all of whom meet international standards for safety and sustainability:

PVC:

We use food-grade PVC resin from Taiwan Formosa Plastics—free from heavy metals (lead, cadmium) and phthalates. This resin has a melt flow rate (MFR) of 1.8-2.2 g/10min, ensuring consistent texture and durability in our tape.

ABS:

For our premium ABS edge banding, we source impact-resistant ABS resin from LG Chem (South Korea). This resin has a Izod impact strength of 18 kJ/m²—2x stronger than standard ABS, making it ideal for high-traffic furniture like office desks and school tables.

Hot Melt Adhesive:

Our proprietary hot-melt adhesive is developed in-house by our R&D team. It’s a blend of ethylene-vinyl acetate (EVA) and thermoplastic rubber (TPR), engineered to withstand high temperatures (up to 180℃) and low temperatures (down to -20℃)—making it suitable for use in kitchens, saunas, and cold storage facilities.

Color Pigments:

We use UV-stable pigments from BASF (Germany) that resist fading even after 10,000 hours of exposure to simulated sunlight (ASTM D4329 standard). This means our edge banding tape won’t fade on outdoor patio furniture or windowsill cabinets.

Every batch of raw material undergoes a 3-step inspection before entering our factory: (1) Certificate of Analysis (CoA) verification from the supplier; (2) in-house testing for purity and consistency; (3) sample production to ensure the material performs as expected. Any batch that fails even one step is rejected—no exceptions.

Other products

Start Your Custom Solution Now

Whether you need edge banding samples, want to discuss custom color schemes, or have any questions about bulk pricing, filling out the form below is the fastest way to contact our team. Our experts will respond to your inquiry within 24 business hours and provide personalized support tailored to your project needs.

After submitting the form, our sales representative will contact you within 6 hours. You can also contact us directly for immediate assistance through the following channels:

- Email: emily.gu@asiaedgebanding.com

- Phone: +86 15618525178