When you touch the mirror-like custom cabinet doors in the showroom, do you notice the tiny details of the edge banding? PVC/ABS/solid wood/aluminum edge banding technology, this often overlooked invisible guardian, directly determines the life, beauty and environmental protection index of furniture. Today we will deeply analyze the secrets of edge banding technology to help you make a wise choice!

Edge banding technology

The core mission of edge banding

Edge banding is not only the “edge decoration” of the board, but also a key process to put on protective clothing for the cut surface of the artificial board through mechanical bonding technology (edge banding machine + adhesive + edge banding strip). Imagine a wardrobe side panel without edge banding – the base material is exposed, formaldehyde is released wantonly, the edges are rough and easy to get wet, and the service life is greatly reduced.

The four core values of edge banding

Visual magician: The edge banding strips of the same color make the cabinet side and the door panel seamless, hide the internal structure of the board (such as moisture-proof aluminum foil), and create a minimalist seamless aesthetic

Durable guardian: effectively resist daily bumps and wear, prevent corners from cracking, and extend the service life of furniture by more than 30%

Moisture-proof barrier: In southern cities where the return of the south wind is rampant, high-quality edge banding can reduce the moisture absorption rate of the board and avoid expansion and deformation (actual moisture-proof edge banding reduces the expansion rate of the board by 67%)

Formaldehyde sealing technique: Strict edge sealing can reduce the formaldehyde release rate by 40%-60%, which is the last line of defense for environmental protection standards

In-depth evaluation of four major edge banding materials

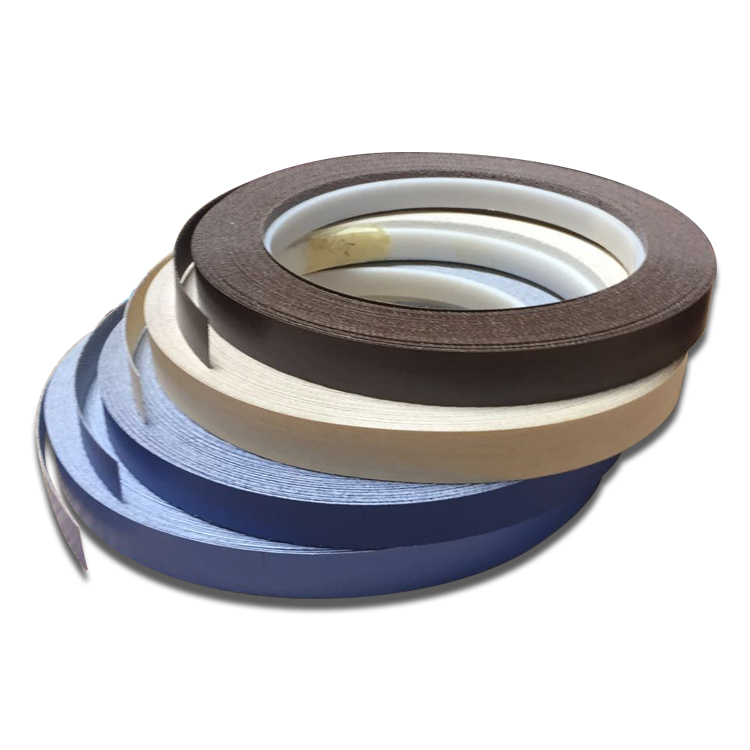

PVC edge banding

Material truth: PVC base material + decorative layer, imitation wood grain accuracy of more than 95%

Performance decoding:

Advantages: cost only 0.3-0.8 yuan per meter, convenient processing, more than 200 color options

Pain points: easy to yellow under sunlight (2-year color difference ΔE>3), low temperature embrittlement (-5℃ impact strength decreased by 40%)

Applicable scenarios: budget project cabinet edge banding, non-sunlight direct area

ABS edge banding

Material revolution: made of terpolymer, 0 heavy metal addition, passed EU REACH certification

Performance breakthrough:

Advantages: mirror effect after trimming (gloss ≥95GU), flame retardant grade B1, recycling rate 100%

Cost: The price is twice that of PVC (1.5-2.5 yuan/meter)

Classic case: A high-end custom brand used A in children’s rooms BS edge banding has been tested for over 5,000 bite resistance times

Solid wood veneer edge banding

Craftsmanship: 0.6mm natural veneer + non-woven backing, more than 20 textures such as oak/walnut

Use warning:

Advantages: Seamless connection with the texture of solid wood cabinet doors, can be curved with the board

Taboo: The expansion rate of the bathroom reaches 3.2% after 6 months of use, and the risk of cracking in the northern floor heating environment increases by 45%

Applicable scenarios: solid wood composite doors, light luxury style display cabinets

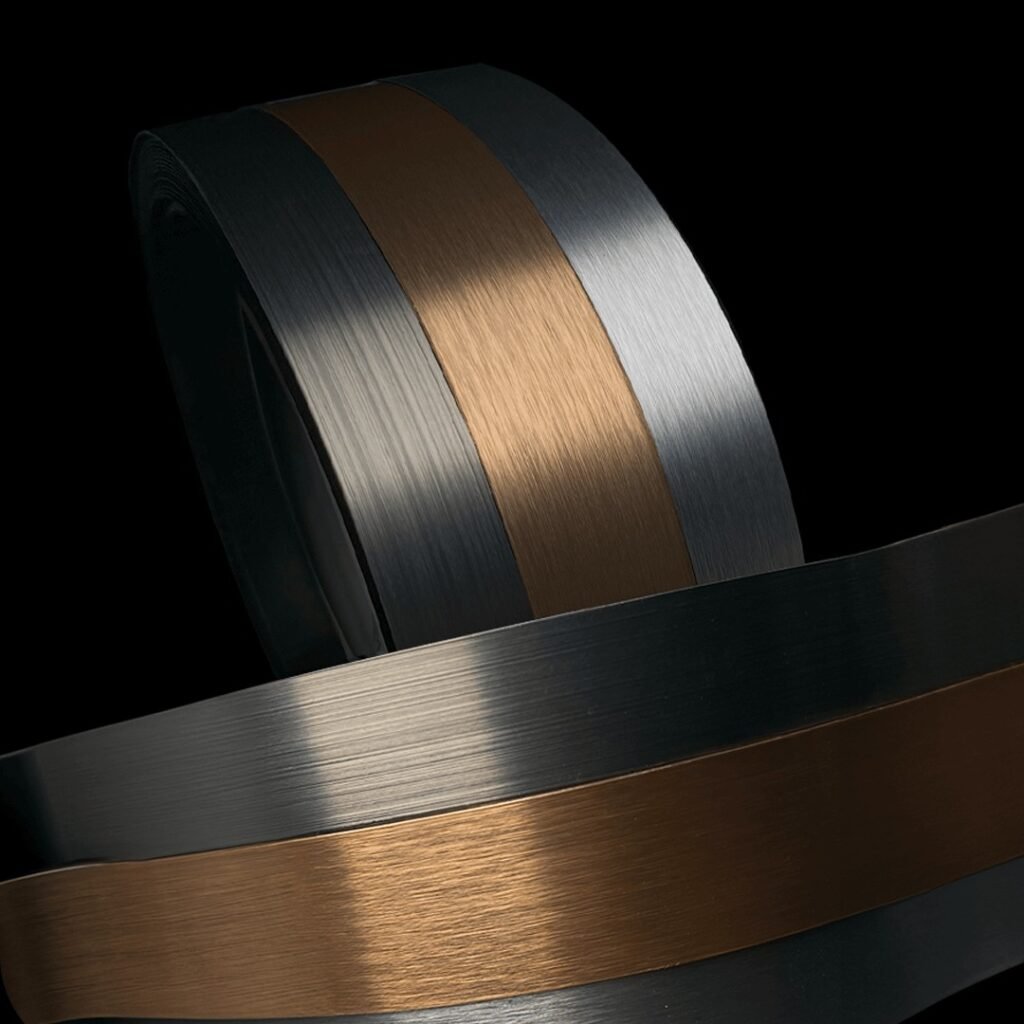

Aluminum alloy edge banding

Metal technology: 6063-T5 aluminum alloy anodized, hardness above HW12

Performance benchmark:

Advantages: 0 rust spots in 10-year corrosion resistance test, impact strength exceeds plastic edge banding by 300%

Limitations: Only suitable for modern style, use with caution on wood grain cabinets (color matching <60%)

Innovative application: A brand of cabinets implants LED light strips with aluminum edge banding at the corners, which is both practical and aesthetic

Three major bonding processes revealed

EVA edge banding: the basic choice

Technology truth: physically cured hot melt adhesive, adhesive layer thickness 0.4-0.6mm

Fatal flaws:

Obvious glue line (width>0.3mm), white cabinets have “black lines” after 1 year

Heat resistance is only 70℃, and the debonding rate in the kitchen environment is 25%

Identification tips: waxy glue overflows on the edge, and white powder can be scraped out by fingernails

PUR edge banding: performance benchmark

Chemical revolution: moisture curing forms an irreversible mesh structure

Shocking data:

Glue line as thin as 0.1mm, no debonding after 72 hours of boiling water immersion

Peel strength reaches 45N/cm, 3 times that of EVA

Avoidance guide: 2023 market sampling shows that 38% of the so-called PUR is actually improved EVA glue

Laser edge banding: the pinnacle of technology

Black technology principle: laser activates the functional layer of edge banding to achieve molecular-level fusion

Actual performance:

Edge banding strength exceeds the substrate itself, and the destructive test occurs inside the board

Zero glue pollution, formaldehyde emission is close to solid wood

Industry status: Only German Homag and other equipment manufacturers have mastered the technology in the world, and the investment in a single machine exceeds 3 million yuan

Leave a Reply