Durable, Aesthetic & Custom-Made for Your Projects

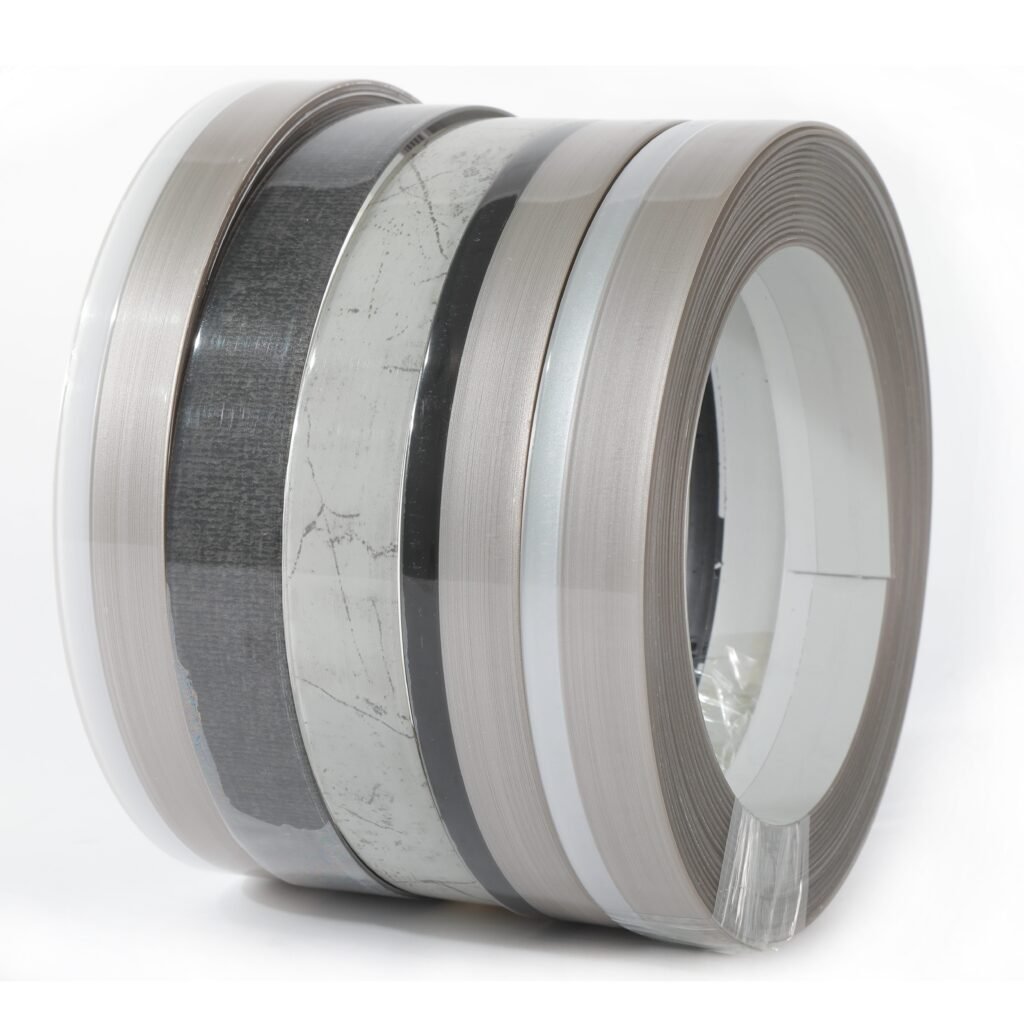

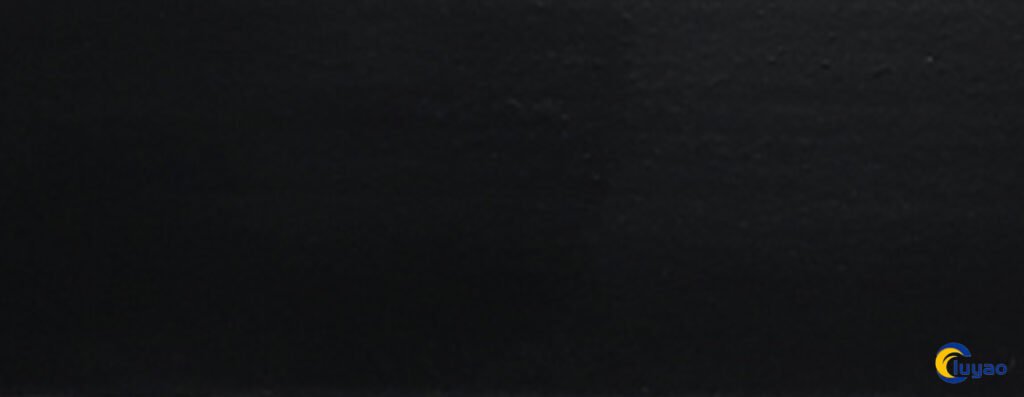

Black Edge Banding Tape Supplier

Looking for reliable, high-performance black edge banding tape to perfect your woodworking or furniture projects? Shanghai Luyao Industry Co., Ltd., a professional manufacturer in China, delivers top-tier black edge banding solutions that combine durability, sleek aesthetics, and precise fitting.

Black Edge Banding Tape Features

Our black edge banding tape is engineered to meet the rigorous demands of both residential and commercial applications. Crafted with high-quality base materials and advanced coating technology, it features a uniform black finish that complements various wood grains, laminates, and solid surfaces. Available in multiple thicknesses, widths, and textures (including matte, glossy, and wood-grain embossed), it seamlessly integrates with your panels to create a polished, professional look.

- Vibrant, fade-resistant black color that retains its appearance over time

- Excellent adhesion when paired with compatible glues (offered by us)

- Resistant to moisture, heat, and daily wear for long-lasting performance

- Flexible design for easy application on curved or irregular edges

- Eco-friendly materials that meet international environmental standards

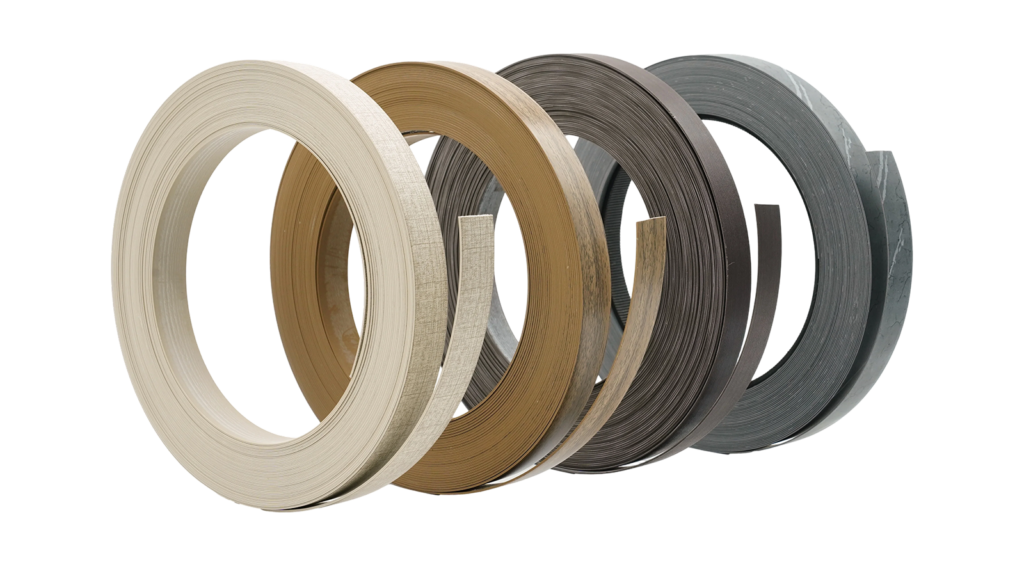

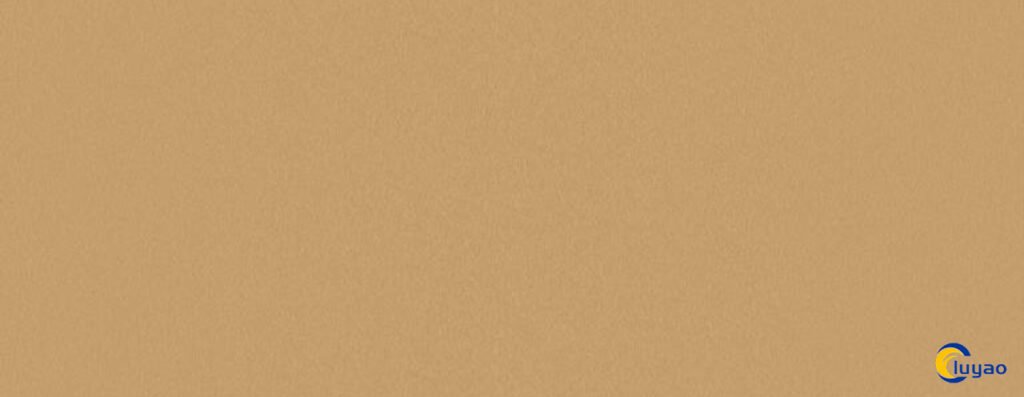

Thousands of color options

Edge banding strips of different materials

About Shanghai Luyao Industry Co., Ltd.

Founded in 2002, Shanghai Luyao Industry Co., Ltd. is a leading professional manufacturer of edge banding tapes in China, with over 20years of experience in R&D, production, and global sales. We specialize in edge banding tape,hot melt glue,PVC film,PVC skirting board, along with a full range of colored and wood-grain edge banding solutions, serving clients in Europe, North America, Southeast Asia, and beyond.

Why Choose Luyao Edge Banding ?

- Professional Factory: 10,000+ sqm production base with 20+ advanced production lines

- Quality Assurance: ISO 9001 certified, with strict quality control from raw materials to finished products

- R&D Capability: In-house R&D team that develops new materials and finishes to meet market trends

- Global Service: Multilingual sales team provides 24/7 support, with fast delivery via Shanghai Port

- Eco-Friendly Commitment: All products comply with EU REACH and US CARB standards

Production Process

- Raw Material Selection: Choose high-purity PVC/ABS pellets and eco-friendly colorants

- Mixing & Melting: Uniformly mix materials and melt at precise temperatures

- Extrusion: Form the base tape through professional extrusion equipment

- Coating: Apply black color coating and protective layer for durability

- Embossing (Optional): Create desired texture (matte, glossy, or wood-grain)

- Cooling & Shaping: Rapid cooling to maintain tape shape and stability

- Cutting & Rolling: Cut to standard lengths and roll with protective packaging

- Quality Inspection: Test adhesion, color fastness, and dimensions before shipment

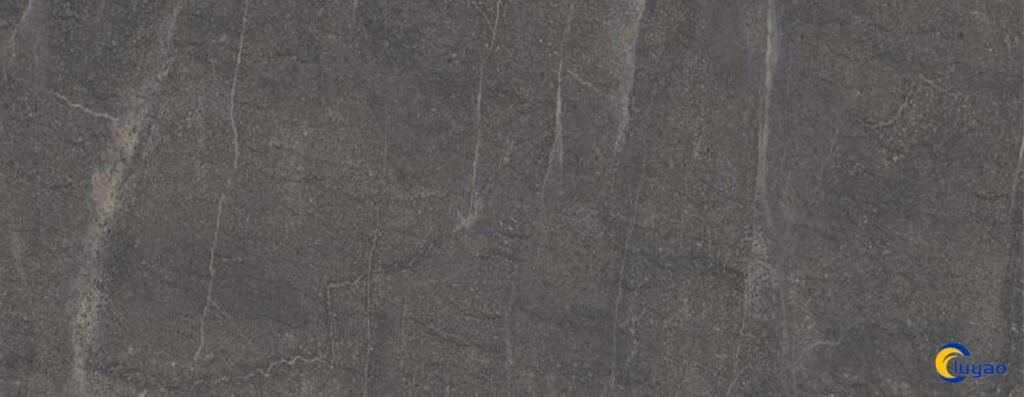

- Sample Display: Experience Our Quality First

Common Questions About Edge Banding Tape

Ready to enhance your projects with our premium black edge banding tape? Fill out the form below, and our professional sales team will contact you within 6 hours to provide a detailed quotation and customized solution.

From Our Blog Posts

High-Quality Edge Banding Tape Manufacturer

Edge banding tape is a critical component in furniture manufacturing, cabinetry, and interior design, serving […]

B2B Edge Banding Selection & Matching Guide – Luyao Expert Solutions

For B2B clients such as furniture manufacturers, cabinet factories, and woodworking enterprises, selecting the right […]

Edge Banding Hot Melt Adhesives – Equipment Compatibility & Industry Solutions

In furniture manufacturing and woodworking processes, the matching degree between hot melt adhesives and edge […]