20 Years of Expertise

china edge banding factory

China’s High-Quality Edge Banding Source Factory, Customized Solutions for Global Furniture Enterprises

Trusted High-Quality Custom Supplier for Global Buyers

Factory Direct Supply to 50+ Countries Worldwide

Factory Direct Price + Flexible MOQ: 5000m MOQ for standard products, small-batch trial orders for customized products, cut out middlemen to save 30% cost.

Comprehensive Customization Capability: Matching 1000+ Pantone colors, 1:1 reproduction of wood/marble textures, dimensional tolerance accurate to ±0.03mm.

Strict Quality Control + On-Time Delivery: 12 inspection items passed for each batch, 7-15 days delivery for standard products, 15-30 day for customized products.

One-Stop Foreign Trade Service: Dedicated personnel follow up the whole process from sample confirmation, production tracking to customs clearance and logistics, multi-language team responds.

Shanghai luyao industry co.ltd

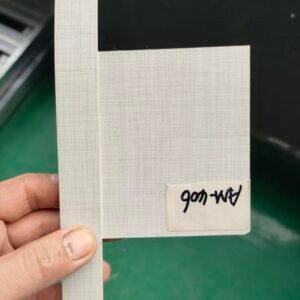

China custom edge banding factory

Our Factory Introduction

Our factory specializes in the research and production of edge banding tapes. We have established 14 intelligent production lines, covering five major series: PVC, ABS, melamine, wood veneer, and acrylic. Our annual production capacity reaches 80 million meters, meeting the bulk purchasing needs of various-sized buyers. We have a total of 200 employees, including an 8-person professional R&D team that invests 8% of our annual revenue in technological upgrades and new product development. A 3-person quality control team monitors the entire production process, and a 20-person foreign trade service team provides multilingual support in English, German, Spanish, and Japanese.

- Raw Material Selection (Displaying test reports for high-purity PVC resin and environmentally friendly additives)

- Mixing and Extrusion (Operating scene of a German KraussMaffei extruder)

- Surface Treatment (Close-up of embossing/printing/lamination processes)

- Quality Inspection (Operation of laser measuring instrument and peel testing equipment)

- Packaging and Warehousing (Moisture-proof film + export-specific carton packaging process)

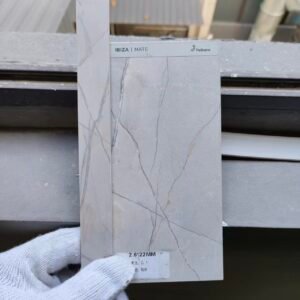

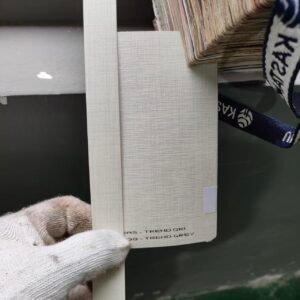

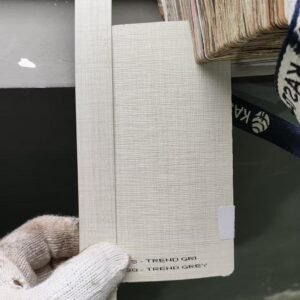

Product Series

Customizable Elements

Accurately Meet Your Needs

- Color: Supports accurate matching of Pantone color card (Pantone C/U), and can also reproduce colors according to customer-provided samples (boards/color cards), color difference ≤ΔE2;

- Texture: 1:1 reproduction of wood grain, cloth grain, metal grain and other textures provided by customers, texture clarity ≥300dpi;

- Size: Thickness 0.3-5.0mm, width 10-120mm, length customizable on demand;

- Function: Can add flame-retardant, antibacterial, high-temperature resistant and other functions according to needs;

- Logo Printing: Supports screen printing, gold and silver hot stamping processes, with high logo clarity and wear resistance without fading.

Custom Process:

Consultation & Communication (clarify needs) → Free Sampling (3-5 working days) → Sample Confirmation (customer acceptance) → Contract Signing → Mass Production → Quality Inspection → Packaging & Delivery.

Solve Pain Points

Edge banding is a critical accessory for furniture manufacturing, cabinetry, and interior decoration, directly affecting product durability, aesthetics, and cost. For overseas buyers, selecting the right edge banding from diverse materials—PVC, ABS, acrylic, wood veneer, and melamine—often faces pain points such as unclear material adaptation, quality inconsistency, high procurement costs, and logistics risks.

Contact Information

Mail: emily.gu@asiaedgebanding.com

Whatsapp:+86-15618525178

- Payment Methods: T/T (Telegraphic Transfer), L/C (Letter of Credit), Western Union (with icons)

- Shipping Terms: FOB, CIF, DDU, DDP (with icons, click to view detailed terms and conditions)