hIGH QUALITY EDGE BANDING FOR EDGE BANDING MACHINE

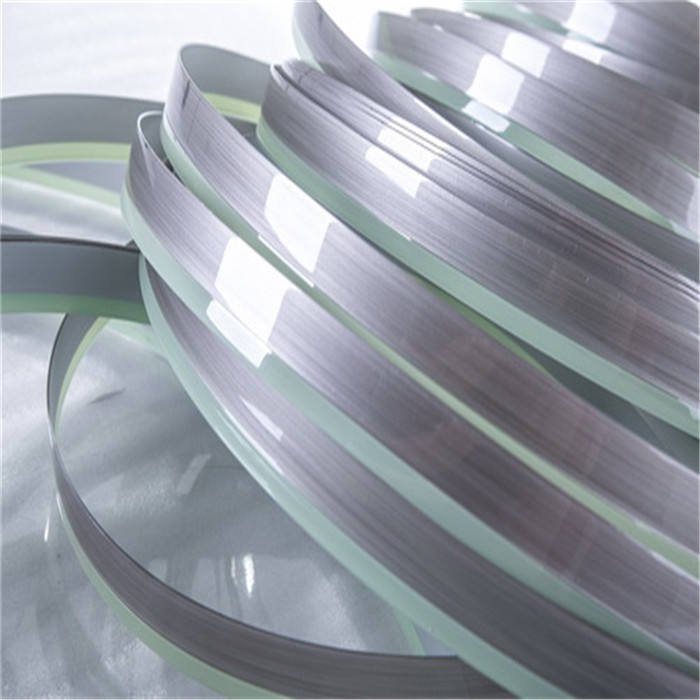

edge banding

At Shanghai Luyao Industry Co., Ltd., we specialize in providing high-quality edge banding solutions that combine aesthetics and functionality.

Our edge banding products are designed to enhance the beauty of your furniture while ensuring durability and ease of use.

The Advantages of Our Edge Banding

- Customized Color Matching: Our edge banding offers precise color matching, ensuring a seamless look between the band and the board.

- Diverse Patterns: Available in a range of finishes, from wood grain to modern metallics, our edge banding caters to various design preferences.

- Durable and Resilient: Our edge banding is made from high-quality materials, providing an extremely durable bond that is resistant to heat and moisture.

- Long-Lasting Finish: With a permanent bond, our edge banding withstands daily wear and tear without losing its appeal.

- Efficient Installation: Designed for use with standard edge banding machines, our products can be applied quickly and efficiently, minimizing downtime.

- Low Maintenance: Our edge banding requires minimal upkeep, making it a cost-effective choice for busy manufacturing environments.

Explore Our Range of Edge Banding Products

Our solid color edge banding is perfect for achieving a uniform look across your furniture pieces. With over 800 color options in stock, you can easily find the perfect match for your project.

Unleash your creativity with our decorative edge banding options. From fine wood grains to striking stone effects, our diverse range allows for endless design possibilities.

They are engineered to resist scratches and fingerprints, ensuring a pristine look over time.

Our special edge banding offers a stunning visual appeal while being lighter and more durable than traditional matel.

Get in Touch

Ready to elevate your woodworking projects with our edge banding solutions? Contact Shanghai Luyao Industry Co., Ltd. today for inquiries and pricing. Let us help you achieve the perfect finish for your furniture and cabinetry!

Edge Banding Type

PVC Edge Banding Strips

PVC edge banding is a popular choice for furniture manufacturing due to its durability and aesthetic appeal. Made from polyvinyl chloride, this edge banding is available in various colors and wood grain patterns, allowing for seamless integration with different surface finishes.

Advantages:

Variety of Thicknesses: Common thicknesses range from 0.5mm to 3mm, with options for custom thickness to suit specific applications.

Moisture and Heat Resistant: PVC edge banding can withstand varying environmental conditions, making it ideal for kitchens and bathrooms.

Easy Installation: It can be applied using standard edge banding machines, providing a quick and efficient bonding process.

ABS Edge Banding Tape

ABS (Acrylonitrile Butadiene Styrene) edge banding is recognized for its superior impact resistance and flexibility. This material is ideal for high-traffic areas and furniture that requires durability.

Advantages:

Variety of Finishes: Available in matte, gloss, and textured finishes, allowing for diverse design options.

High Impact Resistance: ABS edge banding can withstand significant physical stress, making it less prone to chipping and cracking.

Eco-Friendly: Being recyclable, ABS edge banding is a more sustainable choice for environmentally conscious manufacturers.

Melamine Edgebanding

Melamine edge banding is crafted from melamine resin, providing a decorative finish that complements melamine-faced boards. This type of edge banding is known for its vibrant colors and easy maintenance.

Advantages:

Wide Range of Designs: Available in numerous colors and patterns, allowing for customization to match various interior designs.

Scratch and Wear Resistant: Melamine surface coating offers excellent protection against daily wear and tear.

Cost-Effective: It provides a budget-friendly solution for achieving a polished look without the expense of solid wood.

Veneer Edge Banding

Wood veneer edge banding offers the authentic look of real wood, making it a favorite among designers and manufacturers who want to achieve a natural aesthetic. This edge banding is made from thin slices of natural wood adhered to a backing material.

Advantages:

Sustainability: Utilizing thin layers of wood reduces the amount of lumber needed, making it a more sustainable choice compared to solid wood.

Real Wood Appearance: Provides a genuine wood look and feel, enhancing the overall aesthetic of furniture.

Customizable Thickness: Available in various thicknesses, typically ranging from 0.6mm to 1.0mm, allowing for flexibility in application.

Acrylic Edge banding

Acrylic edge banding is known for its high gloss finish and modern appearance. This type of edge banding is made from acrylic materials, providing a sleek, contemporary look for furniture.

Advantages:

Easy to Clean: The smooth surface allows for easy maintenance, making it suitable for both residential and commercial applications.

High Gloss Finish: Acrylic edge banding offers an exceptional reflective quality, adding elegance to any furniture piece.

Durable and Scratch-Resistant: It is highly resistant to scratches and impacts, ensuring a long-lasting finish.

Production Process of Edge Banding

Raw Material Preparation

The first step in producing edge banding is selecting high-quality raw materials. We use various materials such as PVC, ABS, wood veneer, and acrylic to ensure the durability and aesthetic appeal of the products.

Material Mixing

Based on the specific requirements of the products, the raw materials are accurately proportioned and mixed. This stage ensures consistency in the physical and chemical properties of the edge banding.

Extrusion Molding

The mixed materials are processed through an extruder to form the initial shape of the edge banding. This process allows for adjustments in thickness and width to meet customer specifications.

Cooling and Cutting

After extrusion, the edge banding is cooled and then cut. Precision in cutting is crucial to ensure that each piece of edge banding has uniform length and neat edges.

Surface Treatment

To enhance the appearance and durability of the edge banding, we perform surface treatments. This includes coating, spraying, and printing processes that provide better visual effects and scratch resistance.

Quality Testing

Once production is complete, all edge banding undergoes rigorous quality testing. We pay special attention to the following aspects:

Chemical Resistance: Our edge banding is specially treated to effectively resist various chemical agents.

Soaking Test: Samples are soaked in specific liquids for 48 hours to ensure they do not delaminate in humid environments, guaranteeing durability.

Physical Performance Testing: This includes tensile strength, impact resistance, and abrasion resistance to ensure the product’s performance in actual use.

Packaging and Shipping

Edge banding that passes quality testing is packed and prepared for shipment. We emphasize the safety of packaging to prevent damage during transportation.

Through this meticulous production process and strict quality control, we ensure that every piece of edge banding meets industry standards and customer expectations. Our goal is to provide customers with high-quality, high-performance edge banding solutions.