Manufacturer & Supplier

Factory-Direct Edge Banding Tape

Shanghai Luyao Industry Co., Ltd. is a professional manufacturer and global supplier of edge banding tape and hot melt adhesive solutions for furniture and interior applications. With factory-direct pricing and strict quality control, we help customers achieve durable, seamless, and cost-effective edge finishing.

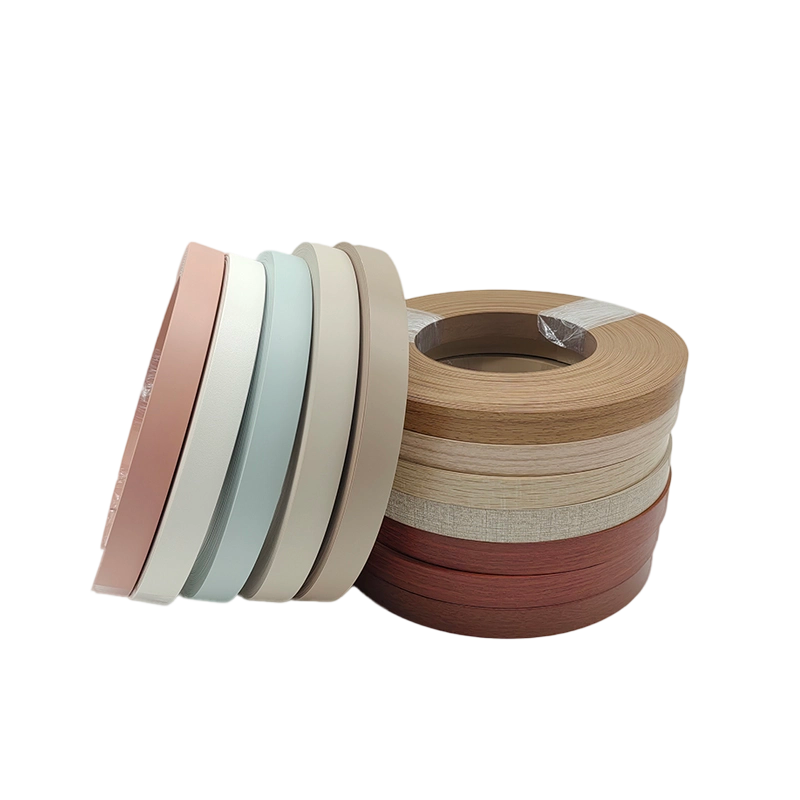

Our Core Products

PVC Edge Banding Tape | ABS Edge Banding Tape | Acrylic Edge Banding | Melamine Edge Banding | Wood Veneer Edge Banding | EVA & PUR Hot Melt Glue

PVC Edge Banding Tape

PVC edge banding tape is a flexible and cost-effective solution for furniture and plywood edge finishing. It provides excellent adhesion, impact resistance, and consistent color matching.

- High flexibility and durability

- Moisture-resistant

- Easy trimming

- Compatible with EVA & PUR glue

ABS Edge Banding Tape

ABS edge banding tape is an eco-friendly and high-performance alternative to PVC, widely used in premium furniture manufacturing.

- Formaldehyde-free

- High impact resistance

- Excellent heat stability

- Suitable for laser edging

Acrylic Edge Banding

Acrylic edge banding offers a high-gloss, mirror-like finish for modern furniture and decorative panels.

- Ultra-high gloss

- Scratch-resistant surface

- Seamless appearance

Melamine Edge Banding

Melamine edge banding is an economical decorative solution, ideal for matching laminated boards.

- Lightweight and cost-effective

- Wide color and pattern options

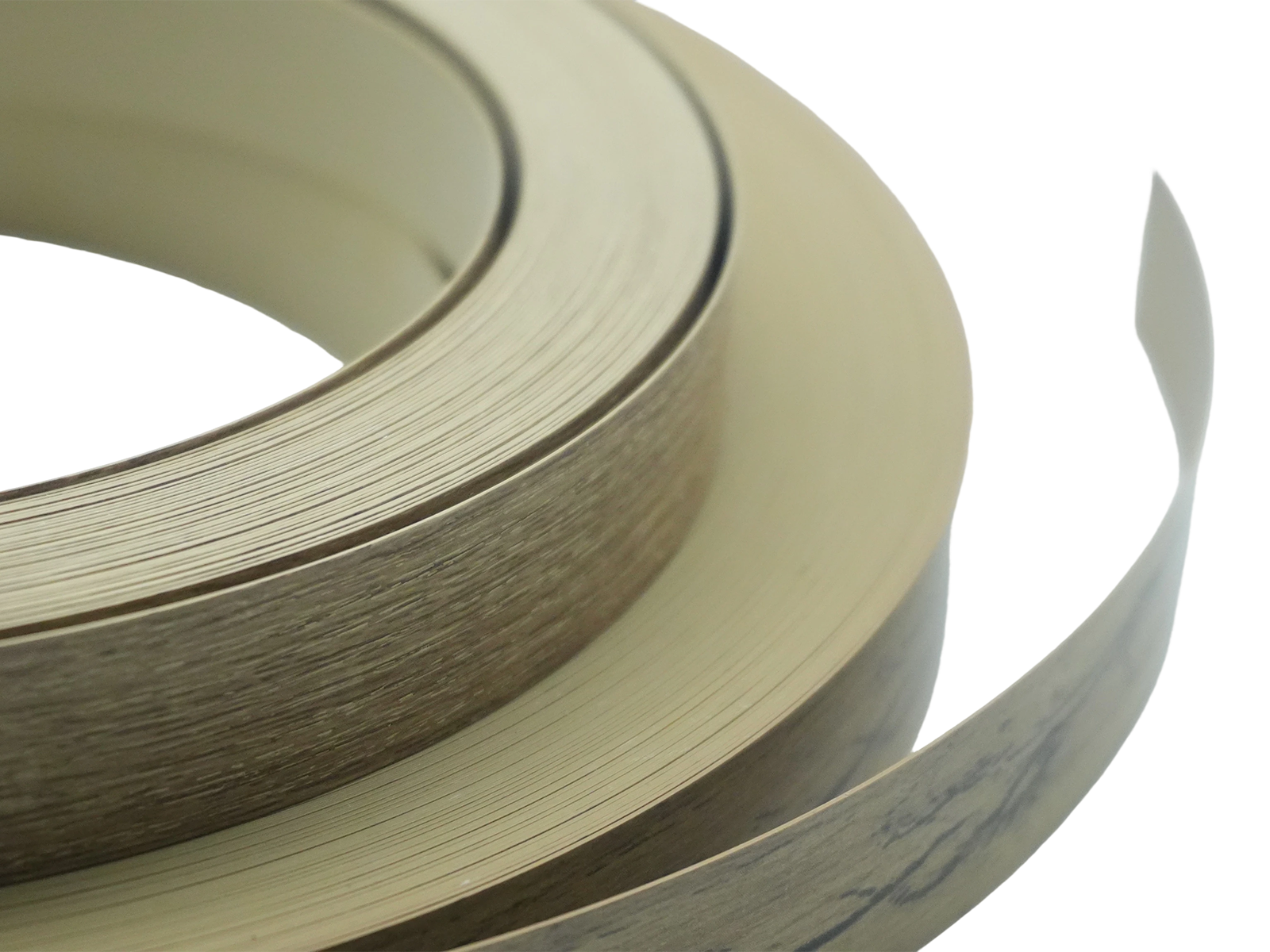

Wood Veneer Edge Banding

Wood veneer edge banding provides a natural wood appearance, perfectly matching solid wood and veneer panels.

- Natural wood grain

- Dense structure, durable and anti-deformation

- Eco-friendly & traceable

- Easy to process & customizable

Get complete plywood edge banding solutions from Luyao.

Glue Recommendation

EVA Hot Melt Glue for Edge Banding

- Cost-effective

- Easy operation

- Strong initial adhesion

PUR Hot Melt Glue for Edge Banding

- Extremely strong bonding

- Excellent moisture and heat resistance

FACTORY & QUALITY

Edge Banding Manufacturing Process

- Raw material selection

- Extrusion & calendering

- Surface finishing

- Backside primer treatment

- Slitting & packaging

Quality Control & Testing

- Thickness & width tolerance

- Adhesion strength

- Heat & moisture resistance

- Color fastness

Tailored Solutions from Luyao

OEM & Custom Edge Banding Manufacturer

As a professional edge banding manufacturer, Shanghai Luyao Industry Co., Ltd. provides comprehensive OEM and custom edge banding solutions for furniture factories, cabinet manufacturers, and interior projects worldwide.

Custom Sizes & Dimensions

recise sizing is critical for smooth trimming and edge durability. Luyao provides:

- Thickness: 0.3mm – 3.0mm

- Width: 15mm – 80mm

- Tight tolerance control for automatic edge banding machines

Custom dimensions are available based on your panel thickness and processing requirements.

Custom Colors & Color Matching

We support professional color matching to ensure seamless integration with your boards:

- Solid colors (RAL, Pantone references accepted)

- Wood grain and decorative patterns

- High consistency across different production batches

Our color matching process helps eliminate visible seams and color deviation in finished furniture.

Custom Surface Finishes

To meet different design and performance needs, we offer multiple surface finishing options:

- Matte and super-matte

- Gloss and high-gloss

- Embossed and wood texture

- Scratch- and heat-resistant coatings

These finishes enhance both aesthetics and durability.

Custom Packaging & Branding

We provide flexible packaging solutions for OEM and private label customers:

- Neutral packaging or branded packaging

- Custom carton labels and barcodes

- Export-ready packaging for long-distance shipping

This allows you to build your own brand while maintaining stable supply.

Get Factory Price from Luyao

Looking for high-quality edge banding tape at factory-direct prices?

👉 Contact Luyao now for samples, technical support, and quotations.