Complete Guide for Furniture & Cabinet Manufacturing

Edge Banding Tape Sizes

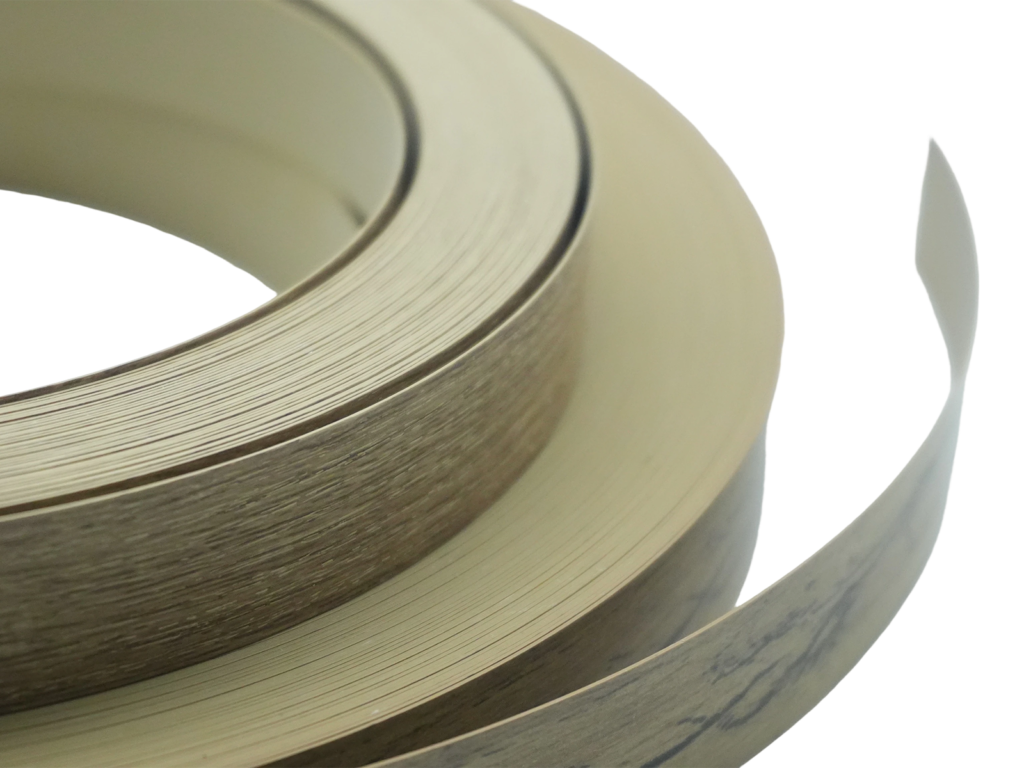

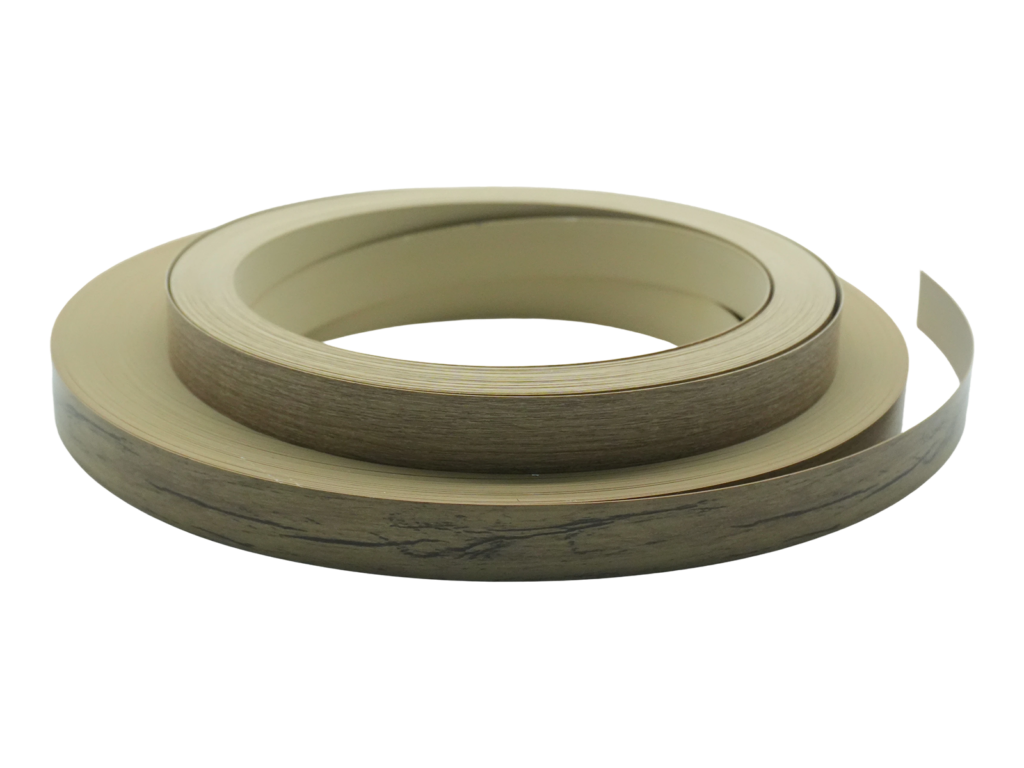

Edge banding tape sizes play a critical role in achieving clean, durable, and professional finishes for furniture panels. Choosing the correct width and thickness ensures proper coverage, strong adhesion, and long-term performance across different applications such as cabinets, wardrobes, and office furniture.

Standard Edge Banding Tape Sizes

Edge banding tape is available in a wide range of sizes to match various panel thicknesses and design requirements.

Common Width Options

- 15mm – Suitable for 12–14mm boards

- 18mm – Ideal for 16–17mm panels

- 22mm – Designed for 18mm boards

- 25mm – 30mm – For thicker panels or extra trimming allowance

- 35mm – 80mm – Used for countertops and specialty applications

Common Thickness Options

- 2.0mm – 3.0mm – Heavy-duty commercial and high-end furniture

- 0.4mm – Light-duty furniture, cost-effective solution

- 0.8mm – Standard cabinet and wardrobe use

- 1.0mm – 1.2mm – Enhanced durability and impact resistance

How to Choose the Right Edge Banding Tape Size

Panel Thickness & Trimming Allowance

Always select an edge banding width 2–3mm wider than the panel to allow precise trimming and a seamless finish.

Furniture Usage Environment

Residential furniture: 0.4–1.0mm thickness Commercial furniture: 1.0–2.0mm thickness High-impact areas: 2.0mm or thicker

Edge Banding Method

Pre-glued tape works best with thinner sizes Hot-melt or laser edging supports thicker and wider tapes

Call to Action

Need help selecting the right edge banding tape sizes for your project?

👉 Contact us now for expert advice, samples, or a customized quotation.

Available Materials & Size Customization

We offer edge banding tape sizes in multiple materials:

PVC Edge Banding Tape

Flexible, cost-effective

ABS Edge Banding Tape

Eco-friendly, durable

Acrylic Edge Banding Tape

High-gloss finish

Melamine Edge Banding

Decorative paper-based

Custom sizes are available upon request, including non-standard widths, thicknesses, and lengths.

Professional Manufacturer of Edge Banding Solutions

Shanghai Luyao Industry Co., Ltd.

Shanghai Luyao Industry Co., Ltd. is a specialized manufacturer and exporter of high-quality edge banding products for the furniture and interior decoration industry. With years of production experience and a strong focus on innovation, Luyao Industry supplies reliable edge banding solutions to customers across Asia, Europe, the Middle East, and the Americas.

Our core products include PVC edge banding, ABS edge banding, acrylic edge banding,wood veneer edge banding and customized decorative edge banding, designed to meet the demands of modern furniture manufacturing. By combining advanced production technology with strict quality control, we help our customers achieve durable, visually seamless, and cost-effective furniture finishes.

Our Manufacturing Process for Edge Banding

At Shanghai Luyao Industry, every roll of edge banding is produced under a standardized and traceable manufacturing process to ensure consistent quality and performance.

1. Raw Material Selection

We use carefully selected virgin PVC, ABS, and acrylic materials with stable physical properties. All raw materials are tested for color consistency, flexibility, and environmental compliance before entering production.

2. Extrusion & Calendering

The materials are melted and extruded through high-precision extrusion lines. During this stage:

- Thickness and width are accurately controlled

- Surface smoothness and gloss level are adjusted

- Color matching is strictly monitored

3. Surface Finishing

Depending on customer requirements, edge banding may undergo:

- Gloss or matte finishing

- Embossing or wood grain texturing

- Protective coating for scratch resistance

This step ensures a natural and uniform appearance that matches furniture panels perfectly.

4. Slitting & Cutting

Large sheets are slit into precise widths and cut into standard or customized lengths. Automated equipment ensures:

- Clean edges

- Accurate dimensions

- Minimal tolerance deviation

5. Inspection & Packaging

Each batch is visually inspected before being securely packed to prevent deformation, moisture exposure, or color variation during transportation.

Looking for a trusted edge banding manufacturer in China?

Contact Shanghai Luyao Industry Co., Ltd. today to discuss your project requirements or request samples.