Furniture EdgeBanding tape: The Best Processes, Tips, and Materials

Furniture edgebanding is an essential technique in furniture and panel construction that not only provides a polished finish but also increases durability. As the edgebanding industry continues to grow (expected to grow at a CAGR of 7.41% from 2021 to 2026), it’s clear that no one wants furniture, cabinets, or panels with rough edges. In this guide, we’ll share valuable tips, techniques, and materials to help you achieve professional results on your next project.

What is furniture edgebanding?

Furniture edgebanding is a thin strip of material used to cover the raw edges of surfaces such as tables and countertops. Its main purpose is to enhance the visual and physical effects of an item and make it more durable. Common edgebanding materials include:

- ABS (Acrylonitrile Butadiene Styrene)

- Acrylic

- Melamine

- PVC (Polyvinyl Chloride)

Furniture edgebanding can match existing materials or provide contrasting colors and textures for a unique effect. This technique not only enhances the aesthetic, but also helps maintain the structural integrity of the furniture, reducing the likelihood of damage. For example, a table with veneer edgebanding strips will resist wear and tear more than a table with exposed edges.

How to Apply Edgebanding

Applying edgebanding is a simple process, especially when using “iron-on” edgebanding. Follow these steps for best results:

- Preparation: Make sure the edges are smooth and flat.

- Cutting the Strips: Trim the edgebanding slightly past the length of the edge you want to cover.

- Ironing: Place the strip adhesive side down on the edge and press with an iron until the glue melts and adheres.

- Flattening: Use a flat edge or block to keep the edgebanding flat while the glue hardens.

- Trimming: Trim excess edgebanding and use an edge trimmer to achieve a clean finish.

- Sanding: Finally, sand the edges for a smooth, polished look.

While this method works well for small projects, larger or more complex pieces may require industrial-grade techniques such as hot melt glue, hot air, or laser edgebanding to achieve a higher-quality finish.

Cutting the furniture edgebanding

Once the edgebanding is applied, accurate trimming is critical. The best tool for this task is a high-quality edgebander operated by a skilled professional to ensure a flat, smooth finish.

Edgebanding Materials

- PVC Edgebanding: The most popular choice, PVC is inexpensive and durable, making it suitable for bedroom and kitchen cabinets. However, it is not recyclable and cannot be refined once damaged. A width of 3 mm is recommended to avoid sharp corners.

- Oak Edgebanding: Oak has excellent durability, is recyclable, and is an environmentally friendly choice. It is strong and resistant to damage, and allows for a more reliable bond using wood glue than adhesive strips. Oak strips are ideal for thicker applications, typically between 8 mm and 10 mm.

- Wood Veneer Edgebanding: Commonly used on plywood and MDF, wood veneer has a solid oak look and great durability. However, it is not heat resistant and may not hold up well in high traffic areas such as kitchens.

- Acrylic Edgebanding: Acrylic edgebanding is known for its high durability and durability, making it ideal for active environments. It can create a 3D effect and is available in PMMA (polymethyl methacrylate), a lightweight, shatter-resistant glass alternative that is easy to shape and color.

How to install edge banding

Preparation: Clean the acrylic surface thoroughly to remove dust and grease. Measure the dimensions accurately to ensure proper coverage.

Gluing: Choose a suitable adhesive, such as hot melt glue or all-purpose glue. Apply evenly along the edge of the acrylic sheet to avoid excessive amounts that affect the appearance.

Installing edge banding: Align the edge banding with the edge of the acrylic sheet and gently press it into place. Use a pressure roller to ensure a strong bond and eliminate bubbles or gaps.

Note: Allow the glue to dry completely before using the sheet. Maintain a dry environment during installation to optimize bonding.

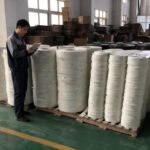

Why choose our edge banding service

If you are looking for the perfect finish, shanghai luyao industry co.ltd provides first-class edge banding services in china. Our team of experts can handle a variety of edge types and materials, including solid wood, veneer, aluminum, ABS and melamine, ensuring that raw edges are transformed into polished perfection.

With more than 20 years of industry experience, we guarantee excellent service at competitive prices. For more information about our edge banding services, please contact us today!

Leave a Reply