Top Tips for Selecting the Ideal

Furniture PVC Edge Banding

PVC edge banding serves as an essential finishing solution in contemporary furniture production, delivering durable and visually refined edges for panel components. As a critical element in manufacturing workflows, this material offers furniture producers and woodworking professionals a high-performance edge treatment that meets commercial quality standards. The technical advantages of PVC edge banding – including its dimensional stability, wear resistance, and finishing consistency – make it indispensable for achieving production-grade results in volume manufacturing environments.

WHY CHOOSE US

What Is Furniture PVC Edge Banding?

Furniture PVC edge banding is a thin strip of polyvinyl chloride (PVC) material used to cover the raw edges of plywood, MDF, particleboard, and other engineered wood panels. It enhances durability, prevents moisture damage, and improves the overall appearance of furniture.

PVC edge banding offers a durable and long-lasting solution, resistant to wear, impact, and daily use, while its moisture-resistant properties make it ideal for kitchens, bathrooms, and high-humidity areas. Available in a wide range of colors and finishes, it seamlessly matches various wood grains, solid colors, and glossy or matte textures. Additionally, its ease of application allows for installation using either heat-activated adhesives or self-adhesive backing, ensuring versatility and convenience.

Luyao Group

Advantages of PVC Edge Banding Over Other Materials

When comparing furniture PVC edge banding to alternatives like ABS, melamine, or wood veneer, PVC stands out for several reasons

Better Moisture Resistance

Unlike wood veneer or paper-based edge banding, which can absorb moisture and lead to swelling, warping, or delamination, PVC edge banding remains completely stable when exposed to water. This superior moisture resistance makes it an ideal choice for bathroom vanities, kitchen cabinets, countertops, and other high-humidity environments where traditional materials fail.

Cost-Effective Solution

PVC edge banding provides an unbeatable balance of affordability and aesthetics. Unlike solid wood trims, which can be costly and require extensive finishing work, PVC edge banding delivers a high-end appearance at a fraction of the price. This makes it an ideal choice for budget-friendly yet sophisticated furniture manufacturing, cabinetry.

Versatile Aesthetic Options

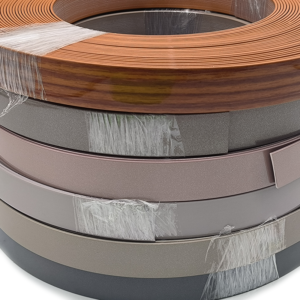

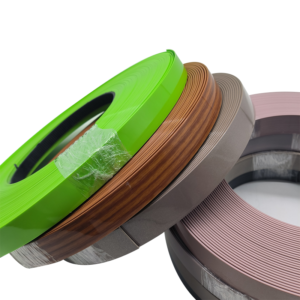

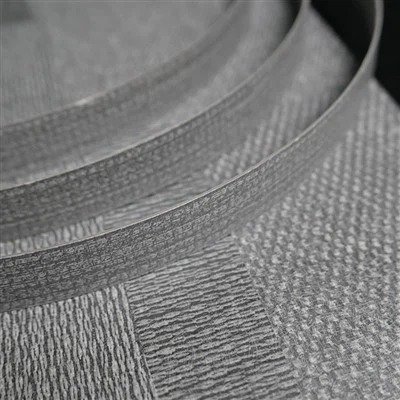

PVC edge banding offers unmatched design versatility, available in realistic woodgrain patterns, vibrant solid colors, sleek metallic finishes, and premium high-gloss effects. Whether replicating natural oak, creating bold contemporary looks, or achieving luxurious reflective surfaces, it seamlessly complements any furniture style—from classic to modern.

Maintenance & Care for PVC Edge Banding

Furniture PVC edge banding is the ideal solution for durable, moisture-resistant, and aesthetically pleasing edges. Whether you’re manufacturing cabinets, office furniture, or custom woodwork, PVC edge banding ensures a professional finish at an affordable cost.

By selecting the right type and applying it correctly, you can enhance the longevity and appearance of your furniture projects.

Gentle Cleaning

For optimal preservation, clean surfaces weekly using a pH-neutral cleaner and non-abrasive textile.

Chemical Protection

Avoid bleach, ammonia, or abrasive cleaners that can cause discoloration or surface degradation.

Edge Inspection

Periodically check for lifting edges; use a household iron (low heat) with a protective cloth to reactivate adhesive if needed.

How to Choose the Right PVC Edge Banding for Furniture?

When selecting PVC edge banding for furniture, it’s essential to consider material, thickness, color, bonding method,

and application scenarios to ensure both aesthetic appeal and durability. Here are the key selection criteria:

Thickness & Width

Thickness (0.4mm~3mm):

Thin (0.4~1mm): Best for flat-panel furniture like bookshelves and wardrobes.

Thick (2~3mm): Impact-resistant, ideal for tabletops and countertops prone to bumps.

Width: Should match panel thickness (typically 15~45mm), with 1~2mm extra for trimming.

Material Selection

PVC Edge Banding: Waterproof, wear-resistant, and cost-effective, ideal for humid environments like kitchens and bathrooms.

ABS Edge Banding: Eco-friendly, odorless, and flexible, suitable for high-end furniture or children’s products.

Solid Wood Edge Banding: Natural texture, but more expensive and requires regular maintenance.

Color & Texture

Wood Grain Patterns (oak, walnut, etc.): Blends seamlessly with solid wood furniture.

Solid Colors (white, black, gray, etc.): Perfect for modern minimalist styles.

Glossy/Matte Finishes: Glossy for a sleek look, matte for better stain resistance.

Bonding Method

Hot-Melt Adhesive: Requires an edge banding machine; strong bond, ideal for mass production.

Thermally activated edge banding with factory-applied adhesive requires only controlled heat application for professional-grade bonding.

Environmental Considerations

Prioritize formaldehyde-free certified products (e.g., EU E1 standard), especially for children’s furniture or bedrooms.

By balancing material, thickness, and aesthetics based on furniture usage, environment, and budget, you can select the most suitable PVC edge banding. Request samples before purchase to test the fit!

Application Scenarios

Kitchen/Bathroom: Choose waterproof PVC with ≥2mm thickness.

Office Furniture: Durable ABS or PVC with a matte finish.

Curved Edges: Use flexible PVC edge banding to prevent cracking.

How Can I Help You

Benefits of Choosing PVC Edge Banding for Furniture

For furniture manufacturers and designers, PVC edge banding delivers an optimal balance of performance, visual appeal, and cost-efficiency

—

establishing it as the premier solution for high-quality furniture production.