When designing or renovating kitchens, kitchen cabinet edge banding plays a pivotal role in both aesthetics and functionality. This comprehensive guide explores cutting-edge materials, eco-friendly innovations, and expert recommendations to help you make informed decisions for durable and visually appealing cabinetry.

Core Materials for Kitchen Cabinet Edge Banding

Selecting the right material ensures longevity and style alignment with your kitchen design:

Key Advantages of Quality Edge Banding

Beyond aesthetics, edge banding addresses critical functional needs:

- Moisture & Mold Resistance

Sealed edges prevent water ingress, protecting particleboard cores from swelling—a common issue in humid kitchens. - Formaldehyde Containment

Laser-edge banding (e.g., Wenxin’s €400K Homag machines) eliminates glue, sealing toxic formaldehyde within boards. This innovation aligns with EU E1 standards (≤1.5mg/L emissions), enhancing indoor air quality. - Enhanced Durability

ABS and PVC resist chipping and scratches, even with heavy utensil use. Thicker banding (2–3mm) provides added protection for cabinet corners.

Cutting-Edge Technologies Shaping the Industry

Stay ahead with these advancements:

- Laser-Fused Edge Banding

Pioneered by brands like LUYAO, this method uses laser-activated polymers for glue-free adhesion. Benefits include zero visible seams, rounded edges for safety, and 15+ years of color retention. - Pre-Glued & Thermal Options

Pre-glued PVC strips simplify DIY installation, requiring only heat activation. Luyao Group’s thermal-bonded edges ensure 98% color matching and rapid production cycles (7–14 days). - Eco-Certified Solutions

Brands like Shanghai Yutong offer SGS-certified, ROHS-compliant banding made from recycled PVC/ABS, reducing environmental impact.

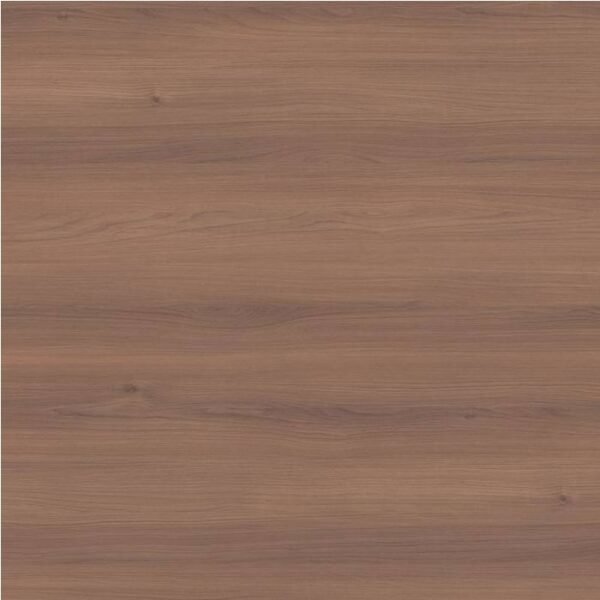

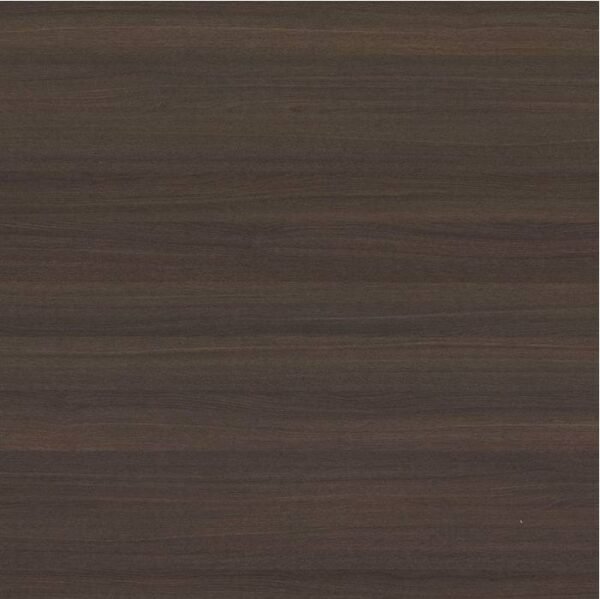

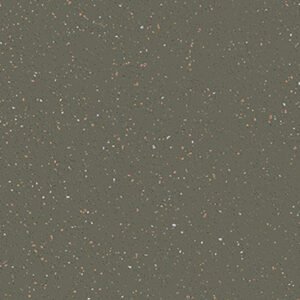

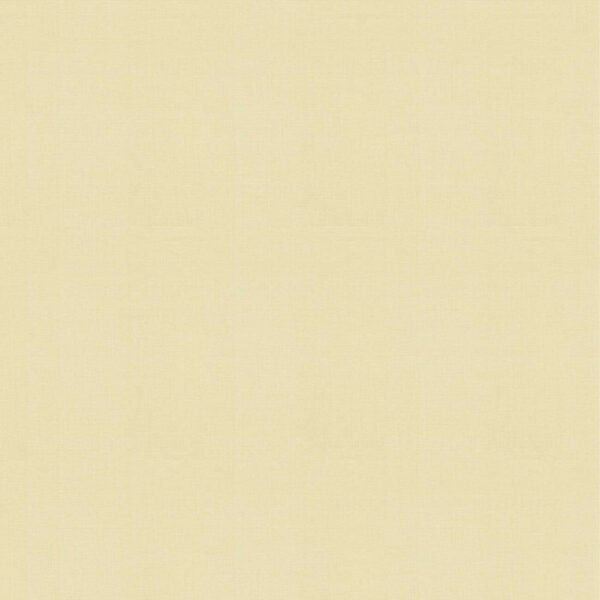

Color design

How to Choose the Perfect Edge Banding

Follow these guidelines for optimal results:

- Match Material to Usage

- High Humidity: Opt for 2mm PVC with PUR adhesive.

- Heavy Use: ABS or 3mm acrylic for impact resistance.

- Outdoor Kitchens: UV-resistant PP banding.

- Prioritize Aesthetic Consistency

Request Pantone/RAL color samples to align with cabinet finishes. - Verify Certifications

Ensure compliance with CARB Phase II, FSC, or E0 standards for low-VOC products.

Maintenance & Longevity Tips

- Clean with pH-neutral cleaners to avoid gloss degradation.

- Inspect seams annually; reapply heat to loose pre-glued edges.

- Avoid abrasive pads to maintain scratch-resistant surfaces.

Edge Banding Manufacturer In China

Contact Luyao Group

Investing in high-quality kitchen cabinet edge banding elevates both form and function. From laser-fused ABS to customizable PVC, innovations ensure durability and style. Partner with certified suppliers like LUYAO Group for eco-conscious, precision-engineered solutions.

Leave a Reply