Description

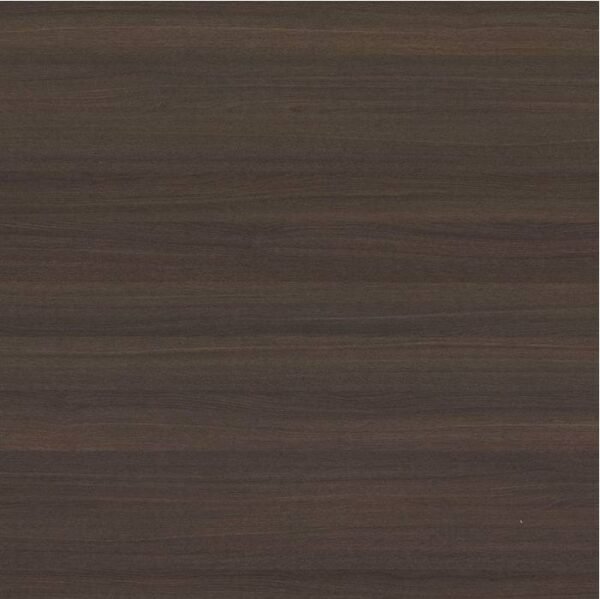

Nevamar 2mm edge banding tape F39

As a global leader in edge banding technology, Shanghai Luyao Industrial Co., Ltd. has been deeply involved in the industry for more than 20 years, focusing on the research and development and production of PVC, ABS, melamine and acrylic edge banding strips.

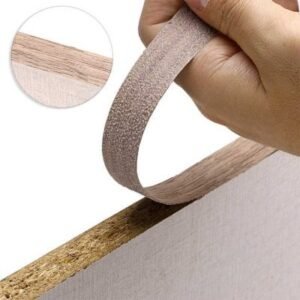

The product thickness covers 0.4-4mm (2mm is a best-selling engineering grade), width 9-120mm, and adopts a composite structure design of the same material to completely solve the problem of cutting white edges.

The wear resistance exceeds the industry standard by 30%, and has passed international environmental certifications such as REACH and CARB-NAF.

The company has a 100,000 square meter intelligent production base, equipped with German Coperion twin-screw extrusion line and Italian laser slitting system, with an annual production capacity of more than 250 million meters, 25 million meters of inventory, and supports 48-hour ultra-fast delivery of white products.

Specification adaptation and function expansion

Size coverage: thickness 0.4-4mm, width 9-120mm, support for special-shaped curved edge banding (T/U shape);

2mm edge banding tape Surface treatment technology

Matte/high gloss: gloss range 10-95GU, adapted to modern minimalist and light luxury style;

3D embossing: imitation wood grain depth up to 0.5mm, texture clarity exceeds the industry standard by 2 times;

Environmental protection and safety certification

Through REACH, CARB-NAF, FSC forest certification, formaldehyde emission ≤0.01mg/m³, heavy metal content meets EU EN71-3 standards;

Flame retardant grade reaches UL94 V-0, smoke density index ≤50, suitable for fire protection requirements in public places.

Comprehensive strength of the enterprise and production guarantee system

Four major production bases: with a total area of over 100,000 square meters, equipped with German KEMPOPLE fully automatic extrusion line and Italian BIESSE CNC slitting system, with an annual production capacity of over 250 million meters311;

Smart warehousing: WMS smart warehousing system achieves 25 million meters of standing inventory, white products are shipped in 48 hours, and customized orders are delivered in 15 days312.

National laboratory: with 60+ testing equipment such as spectrometer and xenon lamp aging box, color difference control ΔE≤1.5 (industry standard ΔE≤3);

Customized services and solutions

1. Color matching system

Cloud color matching: supports instant matching of color numbers of global mainstream board brands (Arborite, Formica, etc.), with color difference ≤2%;

Regional design package: develops six major theme colors such as Asian wood grain, Middle Eastern marble, and Nordic minimalism, and provides scenario-based design proposals312.

2. Functional customization module

- Pur hot melt glue

- EVA hot melt glue

EVA is cheaper than PUR, but PUR has better quality and better cost performance, but it needs to be matched with a suitable 2mm edge banding tape machine. If you need to purchase hot melt glue, please click the link to contact us

Full process production process decryption

1. Raw material pretreatment

Use Swiss BUSS kneading machine for polymer material blending, temperature control accuracy ±1℃, to ensure that the melt flow index (MFI) is stable at 12g/10min.

2. Precision extrusion molding

German Coperion twin-screw extrusion line, die temperature zone control (160-190℃), thickness tolerance ±0.03mm, speed up to 25m/min.

3. Surface modification process

UV curing coating: energy density 800mJ/cm², hardness increased to 3H;

Nano-imprinting: 0.2μm texture accuracy is achieved through silicone transfer roller.

4. Intelligent slitting and packaging

Italian DURIT laser slitting machine, width error ±0.1mm, automatic labeling system to identify batch information;

Industry application scenarios and cases

High-end custom furniture: 2mm edge banding tape is used in the same cabinet system of Italian Poliform, achieving seamless splicing at 45° bevel;

Medical clean engineering: antibacterial edge banding is used in operating room instrument cabinets, and has passed ISO 14644-1 cleanliness certification;

Outdoor landscape facilities: weather-resistant 2mm edge banding tape is used in Dubai beachfront projects and has withstood 2000 hours of salt spray test without corrosion.

Reviews

There are no reviews yet.