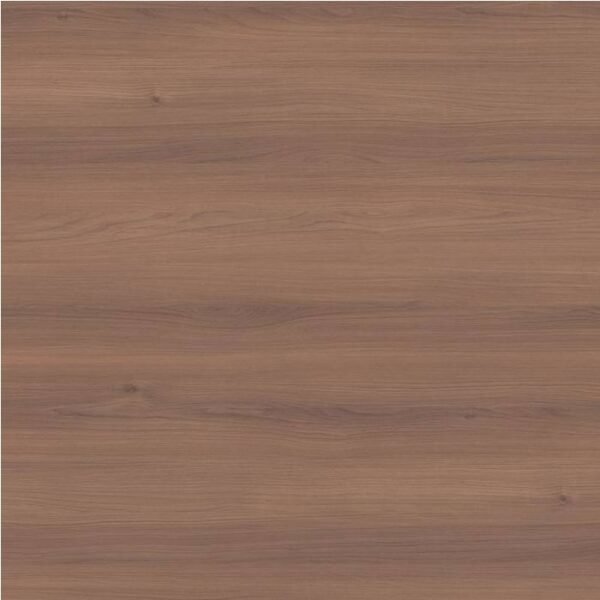

Description

Nevamar mdf edge banding tape F28

MDF edge banding standards

In view of the characteristics of medium-density fiberboard (MDF) that is easy to absorb moisture and deform, our edge banding adopts five-layer composite technology:

- Core layer: high-density PVC substrate (hardness Shore D 82±3), bending strength reaches 120MPa, effectively offsetting the thermal expansion and contraction stress of MDF

- Adhesive layer: Nano-scale hot melt adhesive pre-coating technology (activation temperature 160-200℃), deeply combined with MDF fiber pores, peel strength ≥5N/mm², far exceeding the industry average 3N/mm² standard

- Functional layer: Optional moisture-proof film (water absorption rate <0.1%) or antibacterial coating (antibacterial rate 99.9%), suitable for high humidity environments such as kitchens and bathrooms

- Decorative layer: 3D digital printing technology achieves 0.02mm precision wood grain reproduction, color difference ΔE≤1.5, perfectly matching the MDF facing paper texture

Protective layer: UV-cured wear-resistant coating (scratch resistance level 9H), service life extended to more than 10 years

Engineering-level solution

As the golden specification for mdf edge banding tape, 2mm thick edge banding has unique advantages:

- Structural stability: The thickened design can cover the MDF cutting burrs, and the edge flatness error is ≤0.1mm, avoiding the problem of edge collapse

- Functional expansion: The integrated micro-water guide design effectively guides liquid penetration and protects the MDF core material

- Processing adaptability: Compatible with linear mdf edge banding tape machines (feeding speed 20m/min) and handheld curved edge banding tools, supporting 45° bevel seamless splicing

Environmental performance breakthrough

Passed zero formaldehyde certification (CARB-NAF standard, formaldehyde emission ≤0.005mg/m³), which is 10 times stricter than the E0 standard

Using 30% recycled PVC raw materials, obtained UL ECVP 2799 recycled material certification, carbon footprint reduced by 42%

Full-process quality control system

- Raw material testing: XRF spectrometer is used to screen heavy metals to ensure compliance with EU EN71-3 standards;

- Online monitoring: laser thickness gauge (accuracy ±0.01mm) visual inspection system (defect recognition rate 99.98%) is used during production;

- Laboratory verification: 72-hour salt spray test, 5,000 wear cycle test, -40℃~120℃ extreme temperature change test

The world’s largest design resource library

- Texture database: 1,000+ original textures covering all There are decorative styles including 27 kinds of rare wood species bionic design;

- Color system: 2000+ color numbers instant matching, support 3D rendering effect preview, color difference control ΔE≤1.229;

Sample service upgrade

- 48-hour ultra-fast proofing: 3 candidate samples (length 2 meters) are provided free of charge, and DHL/FedEx global direct delivery is supported;

- Technical adaptation test: adjust the glue layer formula according to customer equipment parameters (such as mdf edge banding tape machine model, rubber roller temperature) to ensure mass production consistency

Factory direct supply price

- Basic white mdf edge banding tape: $0.018/meter (MOQ 5000 meters)

- Other colors contact us for more

Cooperation incentives

Annual purchases of $500,000 will be given exclusive color card service, and enjoy regional protection and price lock

Reviews

There are no reviews yet.