Shanghai Luyao Creates a New Era of Seamless Bonding

PUR hot melt adhesive

Traditional bonding methods often leave noticeable gaps or glue lines between the edge banding strip and the board, affecting aesthetics and easily leading to cracking during use. However, Shanghai Luyao Industrial Co., Ltd.’s PUR hot melt adhesive, during application, achieves a tight bond with the edge banding strip and board, creating a near-perfect fusion effect. Products edge-sealed with PUR hot melt adhesive consistently maintain excellent performance, effectively preventing cracking.

PUR Hot Melt Glue Adhesive Manufacturer

Shanghai Luyao Industrial Co., Ltd., as a professional factory in China, possesses profound expertise and rich experience in the field of hot melt adhesive manufacturing. For many years, Luyao has been committed to the research and innovation of hot melt adhesive technology, continuously investing significant resources in R&D and production, solely to provide global customers with the highest quality PUR hot melt adhesive products.

The company boasts a research and development team composed of senior industry experts and professional technical personnel. They closely monitor international cutting-edge technologies, conduct in-depth research on market demands, and continuously optimize and improve the formulation and production process of PUR hot melt adhesives. From the rigorous selection of raw materials to precise control during the production process, and strict testing before product shipment, every step adheres to international standards and industry specifications, ensuring that every batch of PUR hot melt adhesive possesses superior performance and stable quality.

PUR hot Melt Glue Product Show

Take Action Now and Start Your Partnership!

If you are looking for a PUR hot melt adhesive product that achieves seamless finishes and eliminates edge cracking, and if you desire a long-term, stable partnership with a professional and reliable hot melt adhesive manufacturer, then Shanghai Luyao Industrial Co., Ltd. is undoubtedly your best choice! Click the contact button below and leave your detailed requirements. Our professional customer service team will contact you as soon as possible to provide you with comprehensive consultation services and professional solutions.

Your results are our top priority!

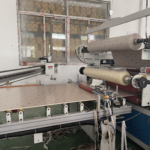

PUR Hot Melt Adhesive Production Showcase

In the raw material selection process, Luyao adheres to stringent standards, partnering only with top global raw material suppliers. All raw materials used in the production of PUR hot melt adhesive undergo rigorous sampling inspection by professional engineers before entering the factory, ensuring that each batch meets our extremely high quality requirements. Only raw materials that pass inspection are allowed to be used in subsequent production processes, providing a solid guarantee for product quality from the source.

Upon entering the production workshop, the first thing that catches the eye is the advanced high-temperature reactor. Here, raw materials, accurately weighed according to a carefully developed formula, are added and begin mixing. Under precise temperature and time control, the raw materials fully fuse, undergoing a series of complex and precise chemical reactions, gradually forming the initial product of PUR hot melt adhesive with unique properties. This process requires extremely high control over reaction conditions, and Luyao, with its years of accumulated production experience and professional technical team, ensures that every reaction achieves optimal results.

Our PUR hot melt adhesives are primarily packaged in aluminum foil bags. Aluminum foil offers excellent barrier properties, effectively preventing the intrusion of moisture, oxygen, and light. PUR hot melt adhesives are extremely sensitive to moisture; the moisture-proof properties of aluminum foil bags prevent premature reactions caused by the absorption of moisture from the air during storage and transportation, thus ensuring their performance. Simultaneously, the good oxygen barrier properties help prevent oxidative deterioration of the hot melt adhesive, extending its shelf life. Furthermore, the light barrier prevents changes in the performance of the hot melt adhesive due to light exposure, ensuring product quality stability.

Regarding packaging specifications, Luyao offers a variety of options to meet the needs of different customers. Common packaging sizes include 20kg packages, which are particularly suitable for manufacturing companies, facilitating transportation and storage and reducing the possibility of waste. For large-scale production companies, we also offer 2kg smaller packages for testing. In packaging design, we emphasize a combination of practicality and aesthetics. Each package clearly displays the product name, model, specifications, instructions for use, precautions, and other important information, allowing you to quickly understand the product characteristics and correct usage before use. Furthermore, we offer customized packaging services; the capacity, shape, and design of the packaging can all be tailored to your specific requirements, helping you enhance product recognition and brand image.

FAQ

Authorized

Real comments

Ahmed Fawzy

Before using Shanghai Luyao’s PUR hot melt adhesive, we were constantly troubled by edge banding cracking, which not only affected product quality but also increased after-sales costs. Since choosing Shanghai Luyao’s PUR hot melt adhesive, these problems have been solved. Luyao’s service team is very professional; they adjusted the adhesive formula according to the characteristics of our solid wood boards in the early stages, and provided regular on-site guidance for construction afterward.

Mallesha

As a food packaging company with extremely high environmental protection requirements, we had previously encountered obstacles due to hot melt adhesive solvent residue issues. Shanghai Luyao’s PUR hot melt adhesive perfectly solved this pain point, with 100% solids content and no volatile content, successfully passing food contact grade testing. Their technical team also specifically optimized the adhesive application parameters for us; their service was incredibly comprehensive.

Mohamad Hawari

Having been engaged in outdoor furniture production for over a decade, edge banding weather resistance has always been a challenge. Our outdoor leisure tables, made with PUR hot melt adhesive from Shanghai Luyao, remained intact and crack-free even after a year in frigid weather, leading to a significant increase in our order volume.

Get Pur Adhesive Sample

We welcome your sample requests. Simply click the “Submit” button at the bottom of the page, fill in your company name, contact information, detailed address, and sample requirements, and submit your application. We will contact you within 6 hours of receiving your application to confirm and arrange for sample shipment as soon as possible. You will receive 1-2 kg of PUR hot melt adhesive samples free of charge, sufficient for your initial testing and evaluation. (Shipping fees apply and can be deducted from the final order amount)