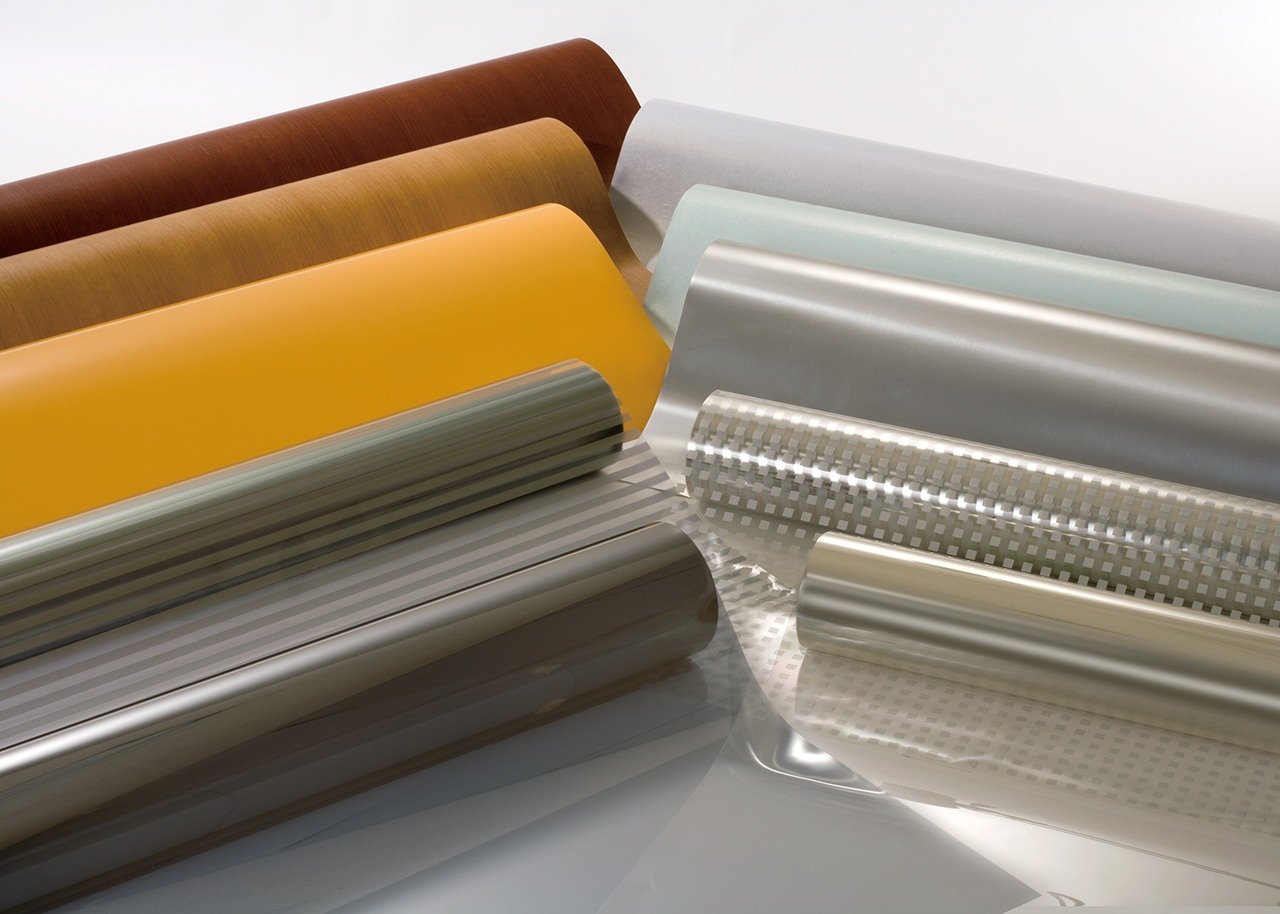

Global demand for sustainable surface solutions drives 22-year manufacturer Shanghai Luyao to pioneer next-generation PVC decorative film technologies.

As dawn breaks over our 100,000㎡ Shanghai production facility, robotic arms precisely calibrate co-extrusion machines for today’s run of anti-UV exterior-grade film – destined for high-rise windows in Dubai. This isn’t science fiction; it’s how modern PVC decorative film manufacturing meets tomorrow’s design challenges. At Shanghai Luyao Industry, we’ve witnessed the decorative surfaces revolution firsthand since 2002, supplying architectural-grade films to 100+ countries from Australia to UAE 3.

Why the Market is Shifting to Advanced PVC Films

- The Sustainability Imperative

Global furniture brands face unprecedented pressure: 73% of consumers now prioritize eco-materials (McKinsey 2024). Our water-based PVC decorative film solves this crisis by eliminating formaldehyde and heavy metals – a claim verified by ISO 14001, REACH, and SGS certifications 1. When a Canadian client switched from traditional laminates to our 0.18mm eco-film series, their VOC emissions dropped 68% while achieving 10-year fade resistance – critical for LEED-certified projects. - The Customization Revolution

Standardization is dead. Last quarter, 45% of our orders required region-specific designs:- Middle Eastern clients requested golden oak films with PMMA coating for desert UV resistance 8

- Scandinavian brands ordered matte white films with Shore D 79±4 hardness for scratch-resistant cabinetry 2

Our digital printing system achieves 98% color matching accuracy – a game-changer when replicating rare marble veins or heritage woodgrains 2.

Technical Breakthroughs Redefining Performance

1. Multi-Layer Co-Extrusion Technology

Our patented 5-layer PVC decorative film structure (developed with German raw materials) creates self-healing surfaces:

- Outer PMMA Shield: 0.1mm UV-absorbing layer passes EN ISO 4892-2 weathering tests

- Air-Slot Adhesive Matrix: Bubble-free application even on curved profiles 8

- Thermal Stability: Withstands -20°C to 80°C thermal shock without delamination 8

2. Functional Surface Engineering

Beyond aesthetics, today’s PVC decorative film must perform:

- Hospitality Grade: Anti-microbial films reduce bacterial growth by 99.3% (ISO 22196)

- Acoustic Films: 0.35mm textured variants absorb 22dB of sound

- Thermoformable Series: 300% elongation capacity for 3D furniture components

Application Intelligence: Where Films Outperform Traditional Materials

Case Study: High-Traffic Office Furniture

A Spanish contract furniture manufacturer replaced laminate with our 0.25mm PVC decorative film series:

- Durability: Taber abrasion resistance of 3,000 cycles (ASTM D4060)

- Cost Impact: 17% material savings vs. solid wood veneers

- Design Flexibility: 1260mm width accommodated oversized conference tables 6

Emerging Applications

- SPC Flooring Wrapping: 0.12mm films withstand 15,000+ footfalls daily

- Outdoor Profiles: PVDF-topcoated films maintain ΔE<3 color shift after 5-year Florida exposure 8

- Marine Interiors: Halogen-free films meet IMO FTP Code for cruise ships

The Sustainable Advantage

Critics question plastics – we’ve responded with circular solutions:

- Bio-Based PVC: 38% plant-derived content (certified by USDA BioPreferred)

- Closed-Loop Recycling: Post-industrial waste recycled into backing layers

- End-of-Life Recovery: Partnering with TerraCycle for film reclamation

“Our accelerated aging tests prove it: properly formulated PVC decorative film lasts longer than the substrates it protects – reducing replacement waste by 60%.”

– Luyao R&D Director, Dr. Wei Zhang

Why Smart Manufacturers Choose Luyao

1. Regionalized Design Intelligence

Our PVC decorative film library isn’t generic. We’ve decoded global preferences:

- South America: Warm teak grains with high gloss

- Asia: Minimalist cement textures

- Middle East: Metallics with embossed patterns 2

2. Agile Production Ecosystem

- Rapid Sampling: 72-hour custom sample turnaround

- Hyper-Customization: Widths from 630mm–1400mm; thicknesses 0.12–0.45mm 6

- Stock Depth: 25 million meters of fast-ship inventory 2

The Future Surface: Where We’re Headed

At our Suzhou innovation hub, engineers are testing:

- Self-Healing Films: Microcapsules repair scratches at 25°C+

- Smart Surface Films: E-textiles integration for capacitive touch

- Phase-Change Films: Thermal-regulating layers reducing HVAC loads

The surface isn’t just the exterior – it’s the experience.

For 22 years, Shanghai Luyao has empowered brands to transform ordinary surfaces into extraordinary interfaces. Our PVC decorative film solutions blend art, science, and responsibility – because in today’s market, beautiful surfaces must also tell a story of innovation and stewardship.

Ready to Engineer Your Surface Revolution?

[Request Custom Samples] | [Download Technical Dossier] | [Schedule Factory Tour]

Leave a Reply