Shanghai Luyao’s ultimate guide to 3 inch edge banding: PVC vs ABS vs PP performance data, manufacturing innovations & selection strategies.

I. Material Properties & Manufacturing Processes

- PVC Edge Banding

- Composition: PVC resin + plasticizers (e.g., DOP/DEHP) + stabilizers + colorants.

- Production: Extrusion molding (170–200°C) with embossed/laminated surfaces.

- Traits:

- Shore hardness: 60–95

- Weak acid/alkali resistance; corrodes in strong chemicals

- Contains halogens (56% chlorine); releases HCl/dioxins when burned

- ABS Edge Banding

- Composition: Acrylonitrile (chemical resistance) + Butadiene (impact strength) + Styrene (processability).

- Production: Co-extrusion (UV-resistant layer + substrate layer, 220–250°C).

- Traits:

- Elongation at break: ≥20%

- Heat deflection temperature: 85–100°C

- Halogen-free & RoHS compliant

- PP Edge Banding

- Composition: Homopolymer/Copolymer Polypropylene.

- Production: Biaxially Oriented (BOPP) with specialty adhesives.

- Traits:

- Resists acids/oils/disinfectants

- FDA food-grade certification

- Low melting point (160–170°C); poor thermal stability

II. Performance Benchmarking

| Parameter | PVC | ABS | PP |

|---|---|---|---|

| Eco-Friendliness | ❌ Phthalate plasticizers | ✔️ Halogen-free & recyclable | ✔️ Food-grade & low-toxicity |

| Weather Resistance | ❌ UV yellowing (ΔE>5 @500h) | ✔️ Color stable 5–8 years (ΔE<1) | ❌ Oxidative brittleness |

| Temp. Range | -10°C to 70°C | -30°C to 100°C | -20°C to 90°C |

| Bonding Method | EVA/PUR glue | Modified PUR adhesive | Plasma-treated surface |

III. Application-Specific Solutions

- Kitchens/Bathrooms:

Luyao ABS Solution: Anti-mold formula withstands 98% RH humidity. Avoid recycled ABS (black speck defects).

Data: 5,000h QUV test shows ΔE<0.8 vs. industry avg. ΔE>2.5. - Medical/Children’s Furniture:

Luyao PP Solution: Passes LFGB migration tests (heavy metals <0.01ppm).

Data: 84 disinfectant resistance >5,000 wipes. - Temporary Displays:

Luyao PVC Economy: $0.18/m (100% virgin material). *Reject recycled PVC (odor VOC>0.5mg/m³)*. - Luxury Cabinetry:

Luyao ABS + Laser Edging: Seamless finish via Homag 592. Verify laser wavelength: 10.6μm.

Luyao popular products

IV. Material Validation Protocols

- Burning Test:

- PVC: Green flame, black smoke, self-extinguishing

- ABS: Yellow flame, sooty smoke

- PP: Blue flame, no smoke, paraffin-like odor

- Solvent Test:

- ABS: Surface dissolves in acetone (swells in 15 sec)

- PVC/PP: No reaction

“Humidity? ABS. Labs? PP. Budget? PVC. Premium? ABS + Laser.”

V. Luyao’s 3 Inch Edge Banding Engineering Breakthroughs

1. Why 3 Inch? Solving Wide-Banding Failures

Global edge banding market grows at 5.8% CAGR (2024: $10.9B), yet >2-inch variants suffer:

- Industry Pain: 23% delamination (EN 14298 test)

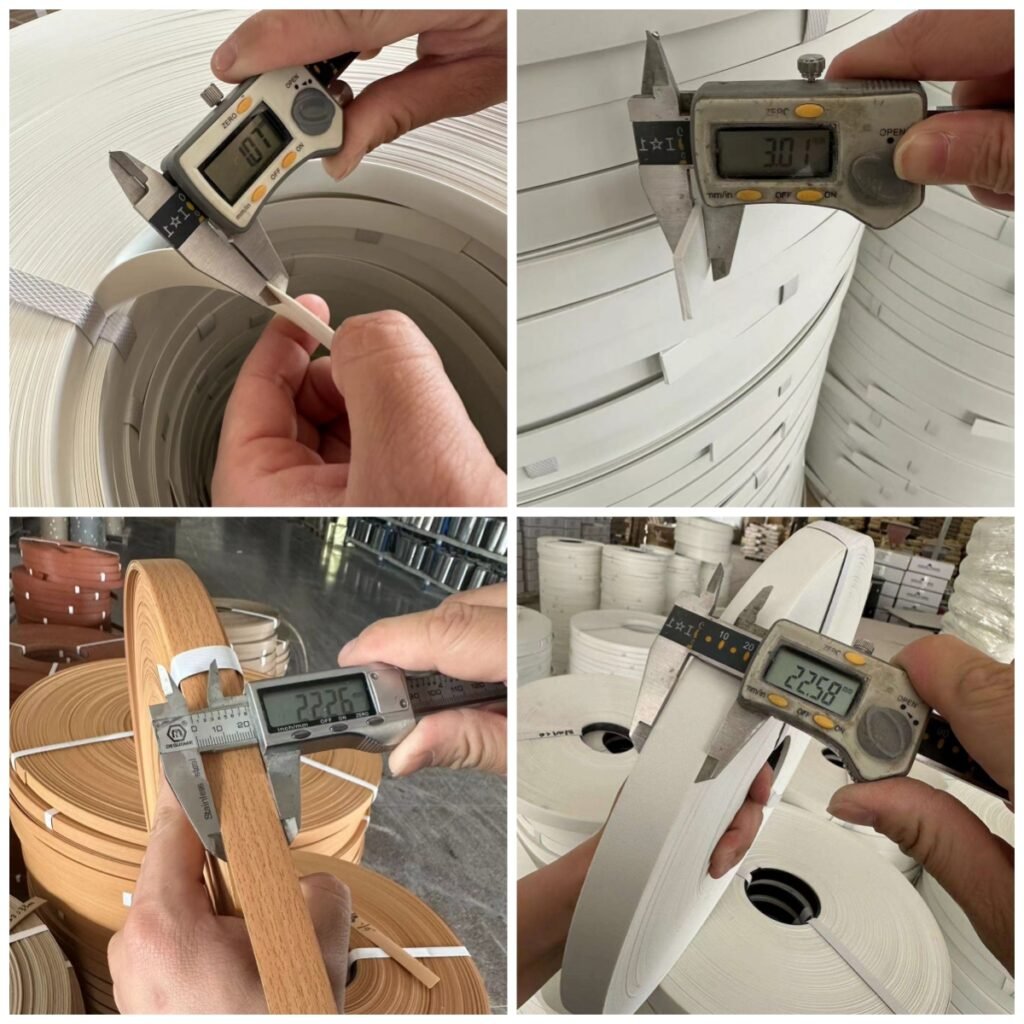

- Luyao Fix: Dual-screw extruder (SJSZ-65/132) achieves ±0.1mm thickness tolerance across 3 inch edge banding.

2. Material Science Innovations

- PVC: Nano-silica additives reduce plasticizer migration – 2-year hardness loss: 8% (vs. 30% industry standard).

- ABS: Butadiene increased to 25% – Impact resistance: 50cm drop height (ISO 6603-2) vs. 30cm standard.

- PP: Co-extruded barrier layer – Chemical resistance 4× baseline.

3. Manufacturing Excellence

| Tech | Industry Standard | Luyao Advantage |

|---|---|---|

| Extrusion Die Design | ±0.3mm thickness deviation | CFD-optimized melt flow: ±0.1mm |

| Surface Finishing | Post-process texturing | In-line gravure printing ($0.15/m saved) |

4. Sustainability Leadership

- Recyclability: Luyao ABS banding = 100% monomer recovery (vs. PVC’s dioxin risk).

- Carbon Footprint: PP banding (0.9g/cm³) reduces shipping emissions by 22% vs. PVC (1.3g/cm³).

5. Future-Proof Solutions

- Biopolymers: Sugarcane-derived PP (2025 launch) – Carbon-negative footprint.

- Smart Banding: RFID-embedded 3 inch edge banding tracks furniture lifecycle (IKEA pilot).

VI. Technical Support & Customization

Luyao’s 3 Inch Edge Banding Toolkit:

- Adhesive Matrix:

- PVC: Standard EVA (peel strength: 4.2 N/mm)

- ABS/PP: Custom PUR formulations (6.8 N/mm)

- Color Matching:

- RAL/Pantone libraries ±0.5 ΔE

- Certifications:

认证:- FDA 21 CFR, REACH, CARB Phase II

Leave a Reply