EVA Hot Melt Adhesive: The Versatile Bonding Solution for Modern Industries

From the moment you unbox a new gadget to the furniture that adorns your home, hot melt adhesives play an invisible yet pivotal role in holding our daily lives together. Among these, Ethylene-Vinyl Acetate (EVA) hot melt adhesive stands out as a cornerstone of modern bonding, thanks to its exceptional flexibility, durability, and adaptability. As a leading manufacturer, Shanghai Luyao Industry Co., Ltd specializes in crafting high-performance EVA hot melt adhesives tailored to diverse industrial demands—from packaging and woodworking to automotive and electronics. In this comprehensive guide, we’ll delve into the science, applications, and advantages of EVA hot melt adhesives, compare them with other types like PUR, and explore why Luyao’s formulations are trusted by businesses worldwide.

What Is EVA Hot Melt Adhesive?

EVA hot melt adhesive is a thermoplastic bonding agent composed of Ethylene-Vinyl Acetate (EVA) copolymer, a synthetic polymer renowned for its balanced blend of flexibility and toughness. Unlike solvent-based adhesives, EVA hot melts are solid at room temperature and activate (melt) when heated to 70°C–100°C (158°F–212°F). Once molten, they are applied to substrates, and as they cool to ambient temperature, they solidify rapidly to form strong, reliable bonds.

At Luyao, our EVA hot melt formulations are precision-engineered with key components to optimize performance:

- EVA Resin: The base polymer that determines core adhesion and flexibility. We adjust vinyl acetate (EVA) content (19%–28%) to tailor properties—higher VA for better flexibility and adhesion to polar substrates like paper and textiles.

- Tackifiers: Rosin esters or hydrocarbon resins that enhance initial stickiness (tack) and improve wetting of substrates.

- Waxes: Paraffin or microcrystalline waxes that modify viscosity and set time—critical for matching production line speeds.

- Additives: Antioxidants to prevent thermal degradation, plasticizers for low-temperature flexibility, and stabilizers for long-term durability.

Key Advantages of EVA Hot Melt Adhesive

EVA hot melt adhesives have maintained their popularity for decades due to their unmatched combination of performance and practicality. Here’s why they remain a top choice for manufacturers:

1. Fast Setting & High Efficiency

With set times as short as a few seconds, EVA hot melts eliminate the long curing waits associated with solvent or epoxy adhesives. This speed is a game-changer for high-volume production lines—such as carton sealing or furniture assembly—where throughput directly impacts profitability. Luyao’s fast-setting EVA formulations reduce work-in-process time and boost operational efficiency for our clients.

2. Solvent-Free & Eco-Friendly

EVA hot melts contain no volatile organic compounds (VOCs), making them safe for workers and the environment. They emit no harmful fumes during application, simplifying compliance with global safety regulations (e.g., REACH, FDA for food packaging). Luyao’s commitment to sustainability is reflected in our bio-based EVA formulations, which incorporate renewable materials to reduce carbon footprints.

3. Versatility Across Substrates & Applications

EVA hot melts bond effectively to a wide range of substrates, including paper, wood, fabric, foam, plastics, and metals (with proper surface preparation). This versatility makes them indispensable in multiple industries—a benefit Luyao leverages to create application-specific solutions, from craft glue sticks to industrial-grade pellets for automated dispensing.

4. Cost-Effective & Easy to Use

EVA hot melts offer an unbeatable price-performance ratio. They require minimal equipment (glue guns for small-scale use, bulk melters for industrial applications) and are easy to set up and clean—reducing maintenance costs. Luyao’s formulations are designed for consistent flow and minimal waste, further lowering total operational costs for our customers.

5. Non-Toxic & Safe for Consumer Goods

Their non-toxic nature makes EVA hot melts ideal for consumer goods like toys, food packaging, and footwear. Luyao’s food-safe EVA grades meet strict FDA standards, ensuring safety in applications where indirect food contact is possible.

EVA vs. PUR Hot Melt Adhesive: Which Is Right for You?

While EVA is versatile, some applications demand the unique properties of Polyurethane Reactive (PUR) hot melt adhesives. Understanding the differences helps you choose the optimal solution—Luyao offers both EVA and PUR formulations to cover all industrial needs. Here’s a detailed comparison:

EVA Hot Melt Adhesive (Luyao’s Strength)

Think of EVA as the “extrovert” of hot melts—versatile, accessible, and adaptable to open dispensing systems. Luyao’s EVA products are available in various forms: glue sticks, beads, pellets, chips, and color options (white, yellow, colorless). Key traits include:

- Open dispensing systems (no need for sealed equipment).

- Longer shelf life (no moisture sensitivity).

- Lower start-up costs (compatible with standard hot melt equipment).

- Fast cure time (seconds) for high-speed production.

- Easy cleanup and rework (reheatable).

- Ideal for: packaging, bookbinding (perfect binding), woodworking (interior parts), crafts, and light assembly.

PUR Hot Melt Adhesive

PUR is the “introvert”—reactive, moisture-cured, and requires sealed dispensing systems to avoid premature curing. It excels in demanding applications where extreme durability is needed:

- Closed dispensing systems (moisture-sensitive before application).

- Forms permanent, crosslinked bonds when exposed to atmospheric moisture (full cure in 2 days).

- Superior bond strength to difficult substrates (low-energy plastics, recycled papers).

- Excellent resistance to extreme temperatures, moisture, and print oils.

- Ideal for: bookbinding (lay-flat books), furniture edgebanding, automotive trim, and outdoor applications.

Luyao’s Expert Tip

Choose EVA if you prioritize speed, cost-effectiveness, and versatility for standard applications. Opt for PUR when you need maximum durability, temperature resistance, or bonding to challenging substrates. Our team can help you select the right type based on your production process and performance requirements.

Applications of EVA Hot Melt Adhesive

EVA hot melt adhesives are the workhorses of countless industries. Shanghai Luyao Industry Co., Ltd supplies tailored formulations to the following key sectors:

1. Packaging & Paper Converting

The packaging industry relies on EVA hot melts for carton sealing, tray forming, envelope sealing, labeling, and paper converting. Luyao’s packaging-grade EVA adhesives offer fast set times and strong adhesion to coated/uncoated paper, waxed stocks, and aqueous coatings—ideal for high-speed packaging lines.

2. Woodworking & Furniture

For veneering, drawer assembly, and interior fixture bonding, EVA hot melts provide reliable performance at moderate temperatures. Luyao’s woodworking formulations ensure tight bonds without damaging wood surfaces, making them a favorite among furniture manufacturers.

3. Textiles & Footwear

Shoe makers use EVA hot melts for liner attachment, insole bonding, and component assembly. The adhesive’s flexibility accommodates the bending and stretching of footwear, while fast set times match high-speed production rhythms. Luyao’s textile-specific EVA grades bond fabric, foam, and leather seamlessly.

4. Electronics & Automotive

In electronics, EVA hot melts secure wire tacking and component assembly, thanks to their non-toxic nature and fast curing. For automotive interiors, Luyao’s low-odor EVA formulations attach fabrics, foams, and trim—safe for cabin environments and resistant to normal temperature fluctuations.

5. Crafts & DIY

Consumer-grade EVA glue sticks (the most common type of hot glue) are perfect for crafts, minor repairs, and prototypes. Luyao’s craft EVA adhesives are easy to use, bond porous/non-porous materials, and are reversible with heat—ideal for hobbyists and DIY enthusiasts.

The Science Behind Luyao’s EVA Hot Melt Production

Producing high-quality EVA hot melt adhesive requires precision at every step. At Shanghai Luyao Industry Co., Ltd, we follow a rigorous 5-step process to ensure consistency and performance:

1. Raw Material Selection & Pre-Mixing

We source premium EVA resins, tackifiers, waxes, and additives from trusted suppliers. Each component is weighed accurately and pre-mixed to ensure uniform distribution—critical for consistent bonding properties.

2. Melting & Mixing

The pre-mixed blend is fed into a heated reactor (120°C–180°C) with an agitator. We melt wax first to create a liquid base, then gradually add EVA resin (to avoid clumping) and incorporate tackifiers/additives. Our state-of-the-art mixing equipment ensures thorough dispersion of all components.

3. Homogenization & Degassing

The molten adhesive is homogenized to eliminate inconsistencies. We use vacuum degassing to remove air bubbles, which enhances bond strength and prevents defects in the final product.

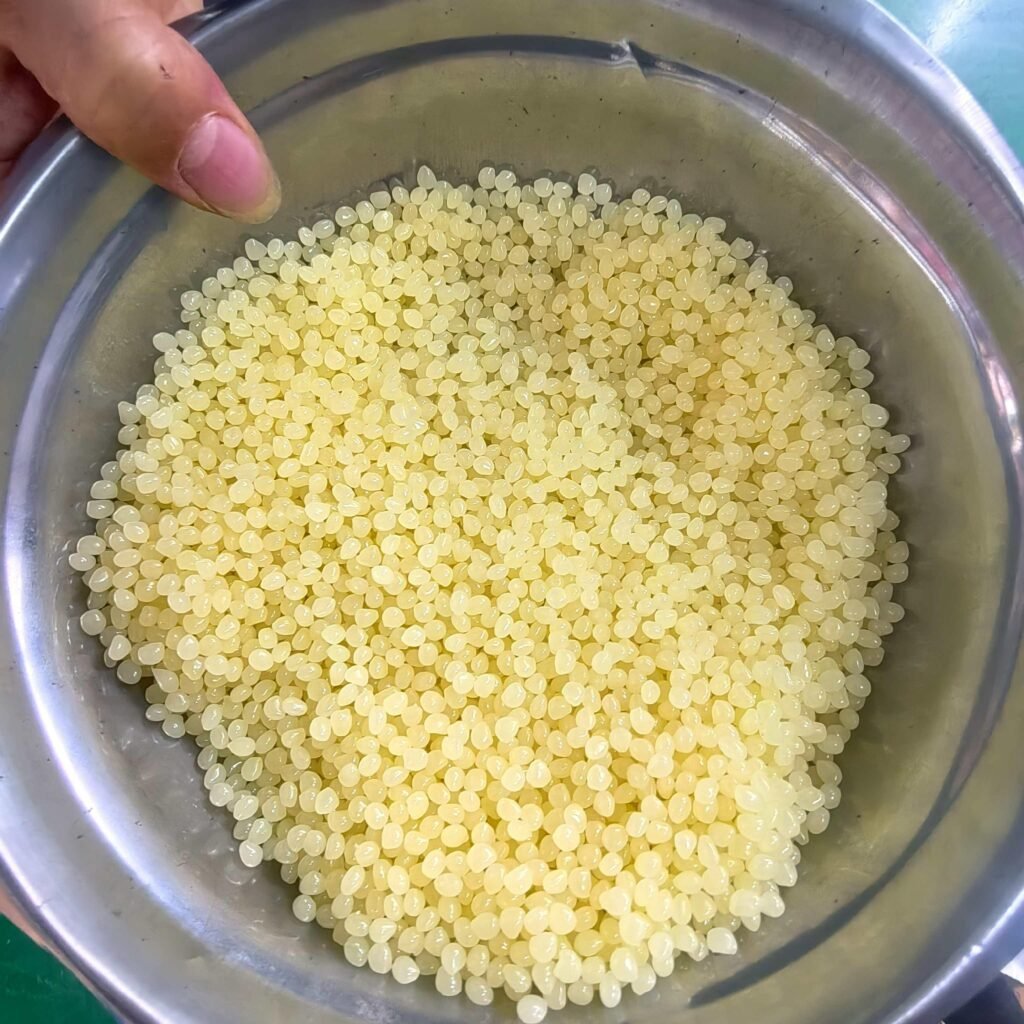

4. Filtration & Extrusion

The adhesive is filtered to remove impurities, then extruded into customer-specific forms: glue sticks (for DIY/craft), pellets (for industrial applicators), or blocks (for large-scale melting tanks).

5. Cooling & Packaging

Extruded adhesives are cooled rapidly (via air or water) to maintain stability, then cut and packaged in moisture-resistant materials to preserve shelf life. Luyao’s packaging is designed to prevent contamination and ensure easy storage.

Latest Trends in EVA Hot Melt Adhesives

As industries evolve toward sustainability and automation, Luyao is at the forefront of innovating EVA hot melt formulations. Key trends shaping the market include:

- Bio-Based Formulations: We’re developing EVA adhesives using renewable feedstocks to reduce environmental impact and meet global sustainability goals.

- Fast-Setting Technologies: Our advanced formulations shorten cycle times further, ideal for automated production lines requiring ultra-high throughput.

- Enhanced Thermal Stability: New additives improve resistance to repeated heating, extending the lifespan of adhesives in high-temperature applications.

- Low-Melt Variants: Formulated to melt at 100°C–130°C, these protect temperature-sensitive substrates like foam, delicate fabrics, and certain plastics.

How to Ensure Effective Bonding with EVA Hot Melt Adhesive

To maximize the performance of EVA hot melt adhesives, follow these best practices—recommended by Luyao’s technical experts:

- Surface Preparation: Ensure substrates are clean, dry, and free of dust, oil, or contaminants. For non-porous surfaces (e.g., plastics), light sanding may improve adhesion.

- Choose the Right Formulation: Match EVA grade to your substrate and application. Luyao’s team can help select the correct VA content, melt flow index (MFI), and set time.

- Control Application Temperature: Maintain consistent heating (325°F–375°F / 160°C–190°C for most Luyao EVA products). Too low, and the adhesive won’t flow properly; too high, and it may degrade.

- Optimize Application Method: Use roll coating for large flat surfaces, spray application for irregular designs, or slot die coating for high-speed, precise dispensing. Luyao’s adhesives are compatible with all standard application equipment.

- Allow Proper Cooling: Ensure bonded substrates remain undisturbed until the adhesive fully sets (seconds to minutes, depending on formulation).

Why Choose Luyao (Shanghai Luyao Industry Co., Ltd) for EVA Hot Melt Adhesives?

With decades of experience in adhesive formulation and manufacturing, Luyao stands out as a trusted partner for businesses worldwide. Here’s what sets us apart:

- Customization: We tailor EVA hot melt formulations to your specific application, substrate, and production needs—no one-size-fits-all solutions.

- Quality Assurance: Our strict quality control processes (from raw material testing to final product inspection) ensure consistent performance batch after batch.

- Sustainability Commitment: We prioritize eco-friendly ingredients and processes, offering bio-based and low-VOC formulations to support your green goals.

- Technical Expertise: Our team of adhesive specialists provides personalized support—from product selection to application optimization and troubleshooting.

- Global Reach: We supply EVA hot melt adhesives to clients across Asia, Europe, North America, and beyond, with reliable logistics and timely delivery.

Frequently Asked Questions (FAQ) About EVA Hot Melt Adhesives

Q1: What is the temperature range for EVA hot melt adhesive?

Most EVA hot melts melt at 70°C–100°C (158°F–212°F) and are applied at 160°C–190°C (325°F–375°F). Luyao’s low-melt variants melt at 100°C–130°C for temperature-sensitive substrates. Service temperature (after curing) ranges from -40°F (-40°C) to 160°F (71°C).

Q2: Is EVA hot melt adhesive waterproof?

EVA hot melts are water-resistant—they perform well in standard humidity and incidental moisture. For continuous water immersion or high-temperature wet conditions, Luyao recommends PUR or specialty adhesives.

Q3: Can EVA hot melt be used for food packaging?

Yes—Luyao offers FDA-compliant EVA formulations specifically designed for food packaging. These are non-toxic and safe for indirect food contact.

Q4: What’s the difference between EVA and PVA glue?

EVA is a thermoplastic hot melt (solid at room temp, melts when heated), while PVA is a water-based liquid adhesive. EVA offers faster setting, better water resistance, and flexibility; PVA is ideal for paper crafts and woodworking where slow drying and clarity are preferred.

Q5: How long is the shelf life of Luyao’s EVA hot melt adhesive?

When stored in a cool, dry, moisture-free environment, Luyao’s EVA hot melts have a shelf life of 12–24 months.

Conclusion

EVA hot melt adhesive is a timeless, versatile bonding solution that powers modern manufacturing. Its fast setting, eco-friendly nature, and adaptability make it indispensable across industries—from packaging to automotive. As a leading manufacturer, Shanghai Luyao Industry Co., Ltd (Luyao) combines technical expertise, customization, and quality to deliver EVA hot melt adhesives that meet the unique needs of businesses worldwide. Whether you’re looking for a cost-effective solution for high-volume packaging or a tailored formulation for delicate electronics, Luyao has you covered.