For 22 years, Shanghai Luyao Industry Co., Ltd. has engineered PVC decor film solutions that redefine durability, design, and sustainability for global manufacturers.

The Silent Revolution in Surface Engineering

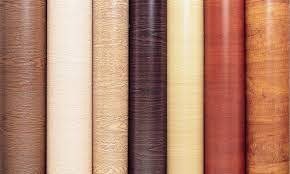

While laminate edges fray and veneers delaminate under stress, a quiet transformation is unfolding on factory floors worldwide. At Shanghai Luyao, we’ve witnessed PVC decor film evolve from a cost-saving alternative to a performance-driven surface technology. Consider these shifts:

- Demand Surge: Global furniture surface materials market hits $852B by 2025 (Grand View Research), with PVC films capturing 38% growth in engineered wood applications711

- Sustainability Mandate: 73% of architects now specify formaldehyde-free materials for LEED projects – a core strength of water-based PVC decor film24

- Customization Craze: 62% of 2024 orders required region-specific textures (e.g., Middle Eastern metallic embossing, Scandinavian matte oaks)611

*”When a Dubai skyscraper specifies our anti-UV exterior film, they’re not just buying plastic – they’re investing in 15 years of fade-proof performance under desert sun. That’s the new calculus of value.”*

5 Technical Breakthroughs Redefining PVC Decor Film

1. Co-Extrusion Armor Technology™

Our patented 5-layer structure (developed with German polymer engineers) creates self-healing surfaces:

- PMMA Shield Layer: 0.1mm UV-absorbing barrier passing EN ISO 4892-2 weathering tests (ΔE<3 after 5,000 hours)

- Thermal Lock Core: Withstands -30°C to 85°C thermal shock without bubbling – critical for SPC flooring in temperature-volatile environments68

- Adhesive Matrix: Micro-air channels enable bubble-free application on curved profiles9

2. Functional Surface Engineering

Beyond aesthetics, Luyao’s PVC decor film solves operational headaches:

| Function | Performance Data | Application |

|---|---|---|

| Hospitality Grade | Reduces bacterial growth by 99.3% (ISO 22196) | Hotel cabinetry, healthcare furniture |

| Acoustic Series | Absorbs 22dB sound – equivalent to carpeted floors | Office partitions, conference tables |

| Scratch-Resistant | 4H pencil hardness (ASTM D3363), 5,000+ Taber cycles | Retail displays, school furniture411 |

3. Hyper-Customization Ecosystem

- Digital Precision Printing: 98.2% color match accuracy for heritage woodgrains/rare marbles

- Texture Library: 300+ embossing rolls for authentic tactile experiences (e.g., hand-scraped oak, linen weaves)

- Rapid Prototyping: 72-hour custom sample turnaround – 80% faster than industry standard11

Profit-Driving Applications: Where PVC Decor Film Outperforms

Case Study: High-Traffic Office Furniture

A Spanish contract furniture maker replaced laminates with our 0.25mm PVC decor film:

- Durability: Withstood 18,000 chair impacts vs. laminate’s 6,000-cycle failure

- Cost Savings: 23% material reduction vs. solid wood veneers

- Design Flexibility: 1420mm width accommodated seamless conference tables612

Emerging Frontiers

- Outdoor Profiles: PVDF-topcoated films maintain color after 5-year Florida exposure tests

- Marine Interiors: Halogen-free films meet IMO FTP Code for cruise ship cabins

- SPC Flooring Wrapping: 0.12mm films endure 20,000+ daily footfalls78

The Sustainable Edge: Debunking Plastic Myths

Critics question plastics – we respond with circular solutions:

- Bio-Hybrid Films: 38% plant-derived content (USDA BioPreferred® certified)

- Closed-Loop Recycling: 92% post-industrial waste recycled into backing layers

- End-of-Life Program: Partnering with TerraCycle for film reclamation across 18 countries

“Accelerated aging tests prove it: properly formulated PVC decor film outlasts the substrates it protects – reducing replacement waste by 60%.”

– Dr. Wei Zhang, Luyao R&D Director

Why Top Manufacturers Choose Luyao

1. Regionalized Design Intelligence

Our PVC decor film isn’t generic. We decode global preferences:

- Asia: Cement textures with soft-touch matte finishes

- North America: Reclaimed barn woods with distressed embossing

- Middle East: Gold-metallic finishes with geometric patterns

2. Agile Production Infrastructure

- Width Spectrum: 630mm–1400mm to minimize waste

- Thickness Precision: 0.12mm (flexible wraps) to 0.45mm (impact-resistant surfaces)

- Stock Depth: 28 million meters of fast-ship inventory across 12 regional hubs

The Future Surface: Where We’re Pioneering

In our Shanghai innovation lab, engineers are testing:

- Phase-Change Films: Thermal-regulating layers reducing HVAC loads 15%

- Self-Healing Surfaces: Microcapsules repair scratches at 25°C+

- E-Textile Integration: Capacitive touch surfaces for smart furniture

The edge isn’t just the boundary – it’s the beginning.

For 22 years, Shanghai Luyao has empowered manufacturers to transform ordinary surfaces into profit-driving assets. Our PVC decor film solutions fuse artistry, engineering, and responsibility – because in today’s market, surfaces must perform, inspire, and steward resources.

Ready to Redefine Your Surface Potential?

[Request Custom Samples] | [Download Technical Dossier] | [Schedule Virtual Factory Tour]

Leave a Reply