What Is Edge Banding Hot Melt Adhesive?

Edge banding hot melt adhesive is a solid thermoplastic adhesive that melts when heated (typically 120°C–210°C) and forms a strong bond as it cools and solidifies. It’s designed specifically for bonding edge banding materials (PVC, ABS, veneer, melamine, fireproof board) to substrate panels (particleboard, MDF, plywood) in furniture manufacturing. Unlike solvent-based or water-based adhesives, hot melt variants offer instant curing, making them ideal for high-speed automatic edge banding machines— a staple in modern furniture factories.

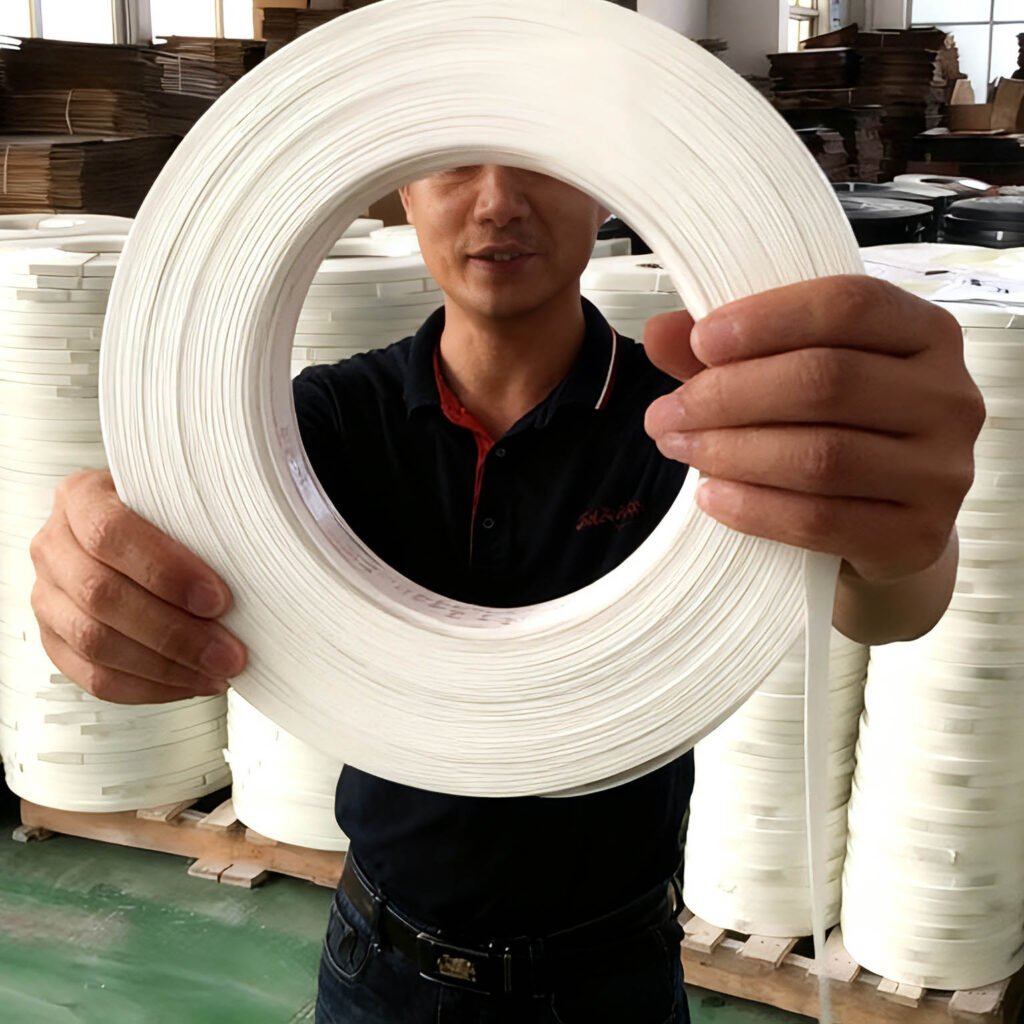

Luyao’s edge banding hot melt adhesive are formulated to address the core challenges of furniture production: consistent bonding, minimal glue lines, and long-term durability. We offer three primary types to match different substrate, material, and performance needs.

Composition of Edge Banding Hot Melt Adhesive (Luyao’s Formulation Expertise)

The performance of edge banding hot melt adhesive depends on its chemical composition and physical properties (density, viscosity). Luyao’s team of chemists optimizes each formulation to ensure compatibility with various materials and production conditions. Here’s a breakdown of key components and their roles:

1. Core Polymer Base

The polymer base determines the adhesive’s fundamental properties. Luyao offers three main polymer types for edge banding:

- EVA (Ethylene Vinyl Acetate): The most widely used option for general furniture manufacturing, thanks to its cost-effectiveness, good flexibility, and broad compatibility. EVA adhesives have a high solid content, preventing blistering, cracking, or edge curling after bonding. They don’t affect the wood’s moisture content— a key advantage for maintaining panel stability. Luyao’s EVA Edge Banding Hot Melt Adhesive are the top choice for mid-range furniture, office cabinets, and mass-produced items.

- PUR (Polyurethane Reactive): A high-performance option for demanding applications (kitchen cabinets, bathroom furniture, outdoor-use items). PUR reacts with atmospheric moisture to form a permanent, crosslinked bond, offering superior moisture and temperature resistance. Luyao’s PUR Edge Banding Hot Melt Adhesive are ideal for high-end furniture or environments with extreme conditions.

2. Key Additives

Luyao’s formulations include carefully selected additives to enhance performance:

- Tackifiers: Improve initial stickiness (tack) to ensure immediate adhesion between edge banding and substrate.

- Waxes: Adjust viscosity and set time— critical for matching the speed of automatic edge banding machines.

- Stabilizers/Antioxidants: Prevent thermal degradation during heating and extend the adhesive’s shelf life.

- Fillers: Increase density (typical range: 0.9–1.65g/cm³) and viscosity strength. Higher density adhesives with more fillers offer better bond durability for heavy-use furniture.

3. Viscosity: A Critical Factor for Bonding Success

Viscosity directly impacts wetting performance and bond strength. Luyao’s technical team helps customers select the right viscosity based on their substrate:

- High Viscosity: Better initial bond strength but lower wetting performance. Ideal for porous substrates like particleboard— the low fluidity prevents the Edge Banding Hot Melt Adhesive from seeping into the panel (which would cause surface glue insufficiency).

- Low Viscosity: Superior wetting performance, ensuring full coverage on smooth substrates like MDF or melamine. Perfect for non-porous edge banding materials (PVC, ABS) that require even adhesive distribution.

Requirements for Panels & Edge Banding Materials (Luyao’s Best Practices)

Even the highest-quality Edge Banding Hot Melt Adhesive will fail if the substrate and edge banding materials don’t meet basic requirements. Luyao recommends following these guidelines to ensure optimal bonding:

1. Substrate (Panel) Requirements

- Low Oil Content: Oily substrates reduce affinity between the panel and adhesive, preventing proper penetration and leading to long-term delamination. Ensure panels are free of grease, dust, or contaminants before edge banding.

- Optimal Temperature: Panel and edge banding temperatures must be above 10°C. In winter or cold workshops, pre-heat materials using hot air, heat lamps, or heated fences near the machine infeed. Cold materials cause false sticking or degumming.

- Controlled Humidity: Substrate moisture content should be 8–12%. Excess moisture causes premature adhesive curing, resulting in weak bonds. Too little moisture reduces adhesive penetration and bond strength.

- Surface Preparation: Sand panel edges to create a rough surface for better adhesive grip. For plywood, ensure edges are smooth and free of splinters.

2. Edge Banding Material Requirements

- Fireproof Board: Residual substances on the back of fireproof board hinder bonding. Pre-treat with all-purpose glue or appropriate solvent before applying Luyao’s edge banding adhesive.

- PVC/ABS/Veneer: Store rolls in closed cabinets (off cold concrete floors) to maintain temperature. Pre-warm rolls for optimal bond formation, especially in cold environments.

- Melamine: Ensure the back surface is clean and dry. Use Luyao’s medium-viscosity EVA or PUR Edge Banding Hot Melt Adhesive for best results.

Cold Weather Edge Banding: Troubleshooting & Solutions

Winter or cold workshops pose unique challenges for edge banding— adhesive thickens, materials are cold, and bond strength suffers. Luyao’s technical team has compiled proven solutions to maintain performance in low temperatures:

1. Machine Setup Adjustments

- Increase Adhesive Temperature: Operate Luyao’s hot melt adhesives at a slightly higher temperature (within the recommended range) to compensate for cold environments. Always refer to Luyao’s Technical Data Sheets (TDS) for temperature limits.

- Verify Glue Pot Temperature: Use an independent temperature probe to confirm the glue pot temperature matches the gauge reading— inaccuracies lead to underheated adhesive.

- Avoid Cold Draughts: Relocate machines away from open doors/windows. Drafts cool adhesive quickly, reducing wetting and bond strength.

2. Material & Environment Management

- Pre-Warm Materials: Use hot air, heat lamps, or machine-mounted heated fences to warm panels and edge banding before application.

- Schedule Production Wisely: Process edge banding later in the day when ambient temperatures are higher.

- Control Workshop Humidity: Low winter humidity can affect PUR adhesive curing. Use humidifiers if necessary (refer to Luyao’s PUR TDS for optimal humidity ranges).

3. Common Cold Weather Issues & Fixes

| Issue | Root Cause | Luyao’s Solution |

|---|---|---|

| Edging easily removed by hand; adhesive transfers to board but not edging | Cold ambient temperature, draughts, cold edging, or underheated adhesive | Check and adjust glue pot/panel/edging temperatures; block draughts; verify feed speed matches adhesive type |

| Edging pulls off; adhesive remains on board (smooth surface, no grid pattern) | Cold board/edging or incorrect primer | Pre-warm materials to room temperature; use Luyao-recommended primer for difficult substrates |

| Edging pulls off; most adhesive on edging | Excess residual board heat or overheated adhesive (low viscosity soaks into board) | Reduce glue pot temperature; use Luyao’s higher heat-resistant adhesive grade |

| No bonding at board front end or splintered edging | Misaligned adhesive application roll or strong roll springback | Adjust roller alignment and associated settings; ensure even adhesive coverage at leading edge |

Hot Melt vs. Water-Based Glue for Edge Banding

Choosing between hot melt and water-based (cold) glue depends on your machinery, production volume, and application type. Luyao offers hot melt solutions for automated lines and collaborates with trusted partners for water-based options when needed. Here’s a detailed comparison:

Edge Banding Hot Melt Adhesive

Best for automatic edge banding machines and high-volume production. Luyao’s EVA and PUR Edge Banding Hot Melt Adhesive are solid granules that melt in a glue pot (180°C–210°C) and cure in seconds as they cool. Key benefits:

- Instant Curing: No waiting for water evaporation— enables immediate trimming and finishing, boosting production speed.

- High Efficiency: Ideal for mass-produced furniture (office cabinets, wardrobes) where throughput is critical.

- Clean Finish: Minimal glue lines when applied correctly; compatible with PVC, ABS, veneer, and melamine.

- Low Maintenance: Solvent-free, so no ventilation requirements; easy to clean from machines.

Water-Based Glue

Best for manual application, curved surfaces, or small-scale workshops without heating equipment. Water-based glues are liquid emulsions that cure by evaporation. Key benefits:

- Long Open Time: Allows adjustments to edge banding position before bonding sets— ideal for curved profiles or manual repairs.

- Deep Penetration: Bonds with wood fibers chemically, offering strong long-term adhesion for custom furniture.

- No Heating Required: Ready to use from the bucket; low upfront equipment cost.

- Higher Heat Resistance: Cured water-based glue often performs better in extreme heat than standard EVA hot melts.

Luyao’s Recommendation

Choose Luyao’s hot melt adhesives (EVA for standard applications, PUR for high-performance needs) if you have automatic edge banding machines and prioritize speed. Opt for water-based glue for manual work, curved edges, or small-batch custom projects.

Hot Melt Adhesive vs. Laser Edge Banding: Which Is Right for You?

Furniture manufacturers often debate between traditional hot melt edge banding (glue-based) and laser edge banding (glue-free). The choice depends on your product positioning, budget, and quality expectations. Luyao’s hot melt solutions are ideal for most mid-range to high-volume production, while laser is suited for premium, seamless finishes.

Hot Melt Edge Banding (Luyao’s Specialty)

Traditional method where Luyao’s hot melt adhesive is applied to edge banding tape, pressed onto the panel, then trimmed. Key traits:

- Pros: Low upfront investment (machines: $5,000–$20,000), easy setup, compatible with most materials, easy to repair/rework, cost-effective for bulk production.

- Cons: Visible glue lines (especially on dark boards), moderate durability (EVA), requires glue management and machine cleaning.

- Ideal For: Small to medium workshops, mass-produced mid-range furniture, office cabinets, and projects where cost efficiency is key.

Laser Edge Banding

Glue-free method using laser/hot air to melt a pre-applied polymer layer on edge banding tape, bonding it directly to the panel. Key traits:

- Pros: Seamless finish (no glue lines), high durability (resists moisture/heat), minimal maintenance (no glue tank), premium aesthetic for high-end markets.

- Cons: High upfront investment (machines: $50,000+), expensive specialty edge banding tape, requires trained operators.

- Ideal For: Premium furniture producers, exporters to EU/US markets, kitchen/bathroom furniture, and brands prioritizing flawless aesthetics.

Cost-Benefit Comparison

| Cost Area | Hot Melt (Luyao) | Laser Edge Banding |

|---|---|---|

| Machine Price | Low to medium ($5k–$20k) | High ($50k+) |

| Operating Cost | Ongoing glue costs, minimal waste | No glue, but expensive specialty tape |

| Maintenance | Regular glue tank cleaning | Minimal |

| Product Value | Mid-range, competitive pricing | Premium, 20–30% higher resale value |

| ROI | 6–12 months | 12–24 months (higher margins) |

Optimal Temperature Range for Edge Banding Hot Melt Adhesive

Temperature control is critical for hot melt adhesive performance. Luyao’s adhesives are formulated with specific temperature ranges to ensure consistent bonding. The optimal range depends on the adhesive type, edge banding material, and substrate:

Luyao’s Recommended Temperature Ranges

- EVA Adhesives: 120°C–140°C. Ideal for PVC, ABS, and veneer edge banding on MDF/particleboard. This range ensures fast melting, even flow, and strong bonding without substrate damage.

- PUR Adhesives: 140°C–160°C. Enables moisture reaction for permanent bonding; suitable for melamine, fireproof board, and high-moisture environments (kitchens, bathrooms).

- Polyamide (PA) Adhesives: 160°C–180°C. For high-temperature applications and premium materials (real wood veneer, acrylic); delivers exceptional heat resistance and bond strength.

Temperature Tips from Luyao

- Always follow Luyao’s TDS for specific adhesive temperature guidelines— never exceed maximum limits (risk of adhesive degradation).

- In cold weather, increase temperature slightly (within TDS range) to compensate for material cooling.

- Use an independent temperature probe to verify glue pot temperature— gauge inaccuracies are common.

- Match temperature to machine speed: faster lines require higher temperatures for proper adhesive flow.

Why Choose Luyao (Shanghai Luyao Industry Co., Ltd) for Edge Banding Hot Melt Adhesives?

As a trusted Chinese manufacturer with global reach, Luyao combines technical expertise, customized formulations, and reliable service to meet the unique needs of furniture manufacturers. Here’s what sets us apart:

- Application-Specific Formulations: We tailor EVA, PUR, and PA adhesives to your substrate (particleboard/MDF/plywood), edge banding material (PVC/ABS/veneer), and production conditions (cold weather, high-speed lines).

- Strict Quality Control: Every batch of Luyao adhesive undergoes rigorous testing for viscosity, bond strength, and thermal stability— ensuring consistent performance across production runs.

- Technical Support: Our team provides on-site troubleshooting, cold weather solutions, and machine setup guidance to maximize adhesive performance and minimize waste.

- Cost-Effectiveness: Luyao’s EVA adhesives offer unbeatable value for mass production, while our PUR/PA grades deliver premium performance at competitive prices.

- Global Logistics: We supply to furniture manufacturers worldwide, with timely delivery and flexible packaging options (granules, pellets) to suit your production needs.

Frequently Asked Questions (FAQ) About Edge Banding Hot Melt Adhesives

Q1: What type of Luyao adhesive should I use for particleboard edge banding?

Use Luyao’s high-viscosity EVA adhesive. Its low fluidity prevents seepage into the porous particleboard, ensuring sufficient surface glue and strong bonding.

Q2: Can Luyao’s adhesives be used for curved edge banding?

For curved edges (manual application), we recommend water-based glue. For automated curved edge banding, use Luyao’s low-viscosity EVA adhesive with extended open time.

Q3: How do I store Luyao’s edge banding hot melt adhesives?

Store in a cool, dry, moisture-free environment (15°C–30°C). Keep EVA/PUR/PA adhesives sealed to prevent contamination; shelf life is 12–24 months when stored properly.

Q4: Does Luyao offer food-safe adhesives for kitchen furniture?

Yes— our PUR adhesives meet FDA standards for indirect food contact, making them ideal for kitchen cabinets and food storage furniture.

Q5: How can I reduce glue lines with Luyao’s hot melt adhesives?

Ensure proper temperature control, use the correct viscosity for your material, and adjust machine pressure/feed speed to ensure even adhesive application. Luyao’s low-bleed formulations also minimize glue lines.

Conclusion

Edge banding hot melt adhesive is a cornerstone of successful furniture manufacturing— and choosing the right product can make or break your production efficiency and product quality. Luyao (Shanghai Luyao Industry Co., Ltd) offers a comprehensive range of EVA, PUR adhesives tailored to diverse needs, from mass-produced office furniture to premium kitchen cabinets. With our technical expertise, cold weather solutions, and commitment to quality, we’re your trusted partner for consistent, durable edge banding results.