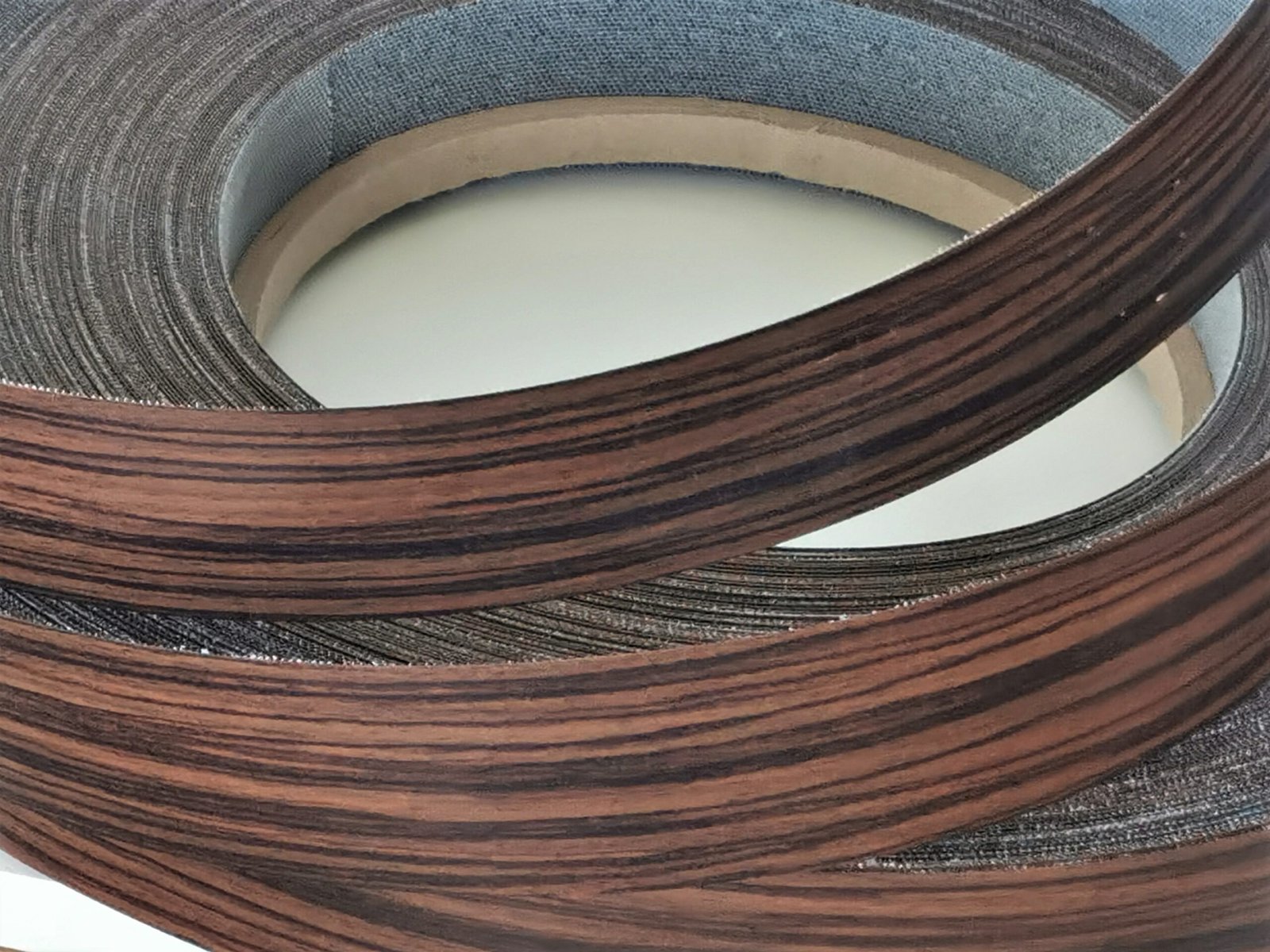

edge banding

Edge banding is an edge covering material for wooden products such as furniture, cabinets and doors. It can tightly wrap the edges and corners of furniture, providing multiple functions such as protection, decoration, moisture-proof and moth-proof. Using high-quality edge banding can significantly improve the durability, grade and overall aesthetics of furniture.

As a professional edge banding manufacturer, LUYAO has a cutting-edge automated production line and strict quality inspection process, and has strong technical strength. We are equipped with an experienced R&D team, focusing on the innovation of new materials and new processes. We are a comprehensive manufacturer integrating R&D, production and sales.

Edge Banding Technical Details

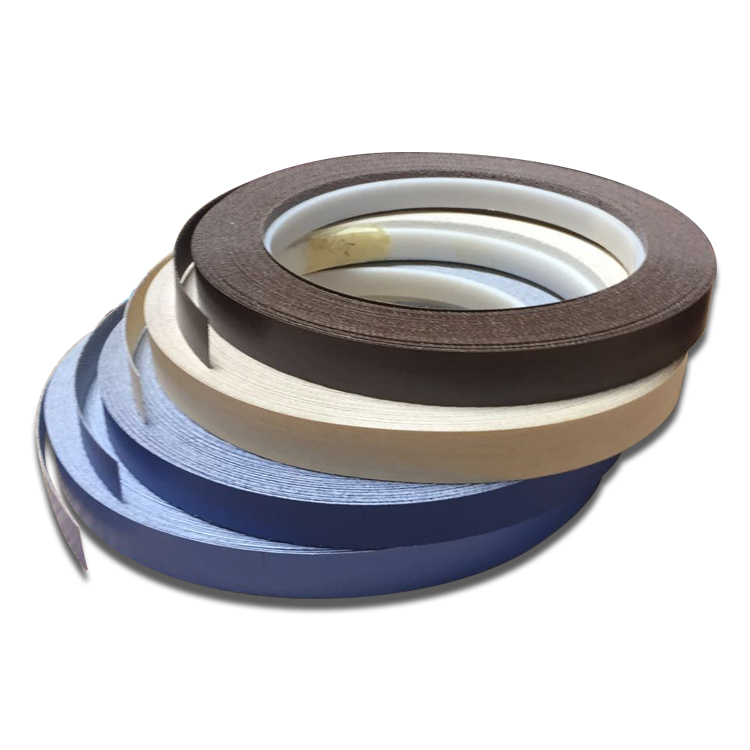

| Thickness | 0.4mm to 5mm, Or customers contact us for customization |

| Width | 9mm to 110mm, Or customers contact us for customization |

| Color | Wood Grain, Solid Color, Cloth Texture, Stone Grain etc |

| Finish | High Glossy, Matte, Super Matte |

| Application | Furniture edge,cabinet edge,drawer edge,table edge,etc. |

| Material | PVC/ABS/Acrylic/Melamine /environmentally friendly materials according to your requirement |

| Features | Featuring non-color variation after trimming, this product delivers superior durability and wear resistance coupled with excellent light stability. It ensures strong bonding strength while offering outstanding resistance to stains and chemicals. |

Manufacturing Complex

|

PVC Edge banding

In cabinets, furniture and various woodworking projects, exposed edges of boards (such as plywood, MDF or particleboard) are not only aesthetically pleasing, but also structurally weak points. This is where PVC edge banding (polyvinyl chloride edge banding) shines. Our PVC edge banding is ideal for edge banding machine sealing process in board/furniture manufacturing

Stable and reliable processing performance

One of the core advantages of Luyao PVC edge banding is its excellent processing adaptability. Its base material and special formula give it excellent physical properties, making it smooth and smooth when cutting, milling and bending, effectively avoiding edge collapse or breakage, and can be easily handled by both semi-automatic edge banding machines and high-speed automatic edge banding equipment. What is particularly critical is that the precision-treated surface of Luyao edge banding shows excellent compatibility with high-quality hot melt adhesive coating. It can form a strong and lasting bond with EVA and PUR=hot melt adhesive, effectively eliminating the common “opening glue” and “degumming” phenomena in later use, and ensuring the permanent firmness of the edge banding effect.

Rich color texture

Luyao has made great efforts to create an extremely rich and trendy color texture system with about 2000+ colors. The product line includes classic and timeless pure color series, such as high-gloss white, elegant black, and warm beige; fashionable and popular colors, such as Morandi gray, metallic texture, and macaron color; and highly simulated wood grain series, with delicate and realistic textures, natural and vivid colors, and perfectly reproduce the natural texture of precious woods such as oak, walnut, and teak. Luyao’s diverse choices can seamlessly adapt to any furniture style and interior decoration theme from minimalist modern, light luxury style, to Nordic style, retro nostalgia, etc. We can also customize your needs, with a similarity of up to 99.8%, and come to sample customization

Strict quality testing, long-lasting durability

Luyao will verify each shipment through strict testing standards: 1. Trimming Test: Professional trimming tools are used to trim the edge-banded panels, and the luyao edge banding strips show excellent edge stability. After the test, the edges are smooth and clean, without any whitening, cracking or delamination, ensuring the exquisite beauty and long-term quality of the edge banding effect. 2. Folding Test: The edge banding strips are repeatedly bent with strong force to simulate the impact resistance and fatigue resistance under extreme use conditions. Even after more than 30 extreme bends, it remains intact without breaks or cracks. This fully demonstrates its extraordinary durability and impact resistance, and effectively copes with the challenges that furniture may face in daily use and transportation.

Luyao provides high-quality PVC edge banding. Whether it is a standard stock series that meets regular needs or customized production services for special designs or large-volume orders, we can respond flexibly. Luyao PVC edge banding has extremely rich optional specifications: covering a variety of popular colors, realistic wood grain and stone grain and other surface textures, as well as a variety of practical thicknesses and widths, ensuring that it can accurately match the unique needs of any furniture manufacturing or decoration project, providing you with a one-stop edge banding solution.

Choosing Luyao edge banding means choosing top quality, rich choices and reliable services backed by strong factory strength, giving your furniture lasting charm and solid protection.

|

ABS Edge banding

As a leader in edge banding solutions with more than 20 years of experience, Shanghai Luyao is committed to providing high-performance ABS edge banding. ABS (Acrylonitrile Butadiene Styrene) material stands out for its chlorine-free, fully recyclable and environmentally friendly characteristics, meeting the increasingly stringent global green manufacturing standards (such as RoHS), and no harmful gases are released when incinerated. Its core advantage lies in its excellent flexibility and impact resistance, which can perfectly fit various special-shaped curves (internal and external curvatures), providing seamless and durable edge protection for cabinets, bathroom cabinets, display cabinets and even car interiors. Luyao ABS edge banding has excellent resistance to moisture, heat and chemical corrosion, and is especially suitable for high-demand environments such as kitchens and bathrooms. We provide 10,000+ precise color matches worldwide (color difference ≤2%), and support flexible customization specifications (thickness 0.4-3.0mm, width 10-80mm).

Built Tough, Defying Daily Wear & Tear

Renowned for exceptional strength and resilience, PVC edge banding effectively shields against impacts, scratches, and the rigors of daily use. It acts as a durable “armor” for panel edges, ensuring they remain intact and resistant to chipping or cracking over time.

Superior Moisture Resistance

Thanks to PVC’s inherent water-repellent nature, this edge banding is ideal for humid environments like kitchens and bathrooms. It effectively blocks moisture ingress, preventing core swelling, warping, or decay caused by water absorption.

Endless Design Options

Boasting an extensive palette of colors, wood grains, stone effects, and solids, PVC edge banding seamlessly complements or creatively accents any substrate. Achieve a flawless match or a bold contrast to realize your unique design vision with ease.

In terms of environmental protection and performance, ABS edge banding is significantly better than PVC. Environmental protection and burden-free are the core genes of ABS: it does not contain chlorine, is 100% recyclable, and does not contain dioxins when incinerated (RoHS compliant), while PVC contains chlorine that is difficult to degrade and releases toxic gases when incinerated. In terms of physical properties, ABS exhibits three advantages: ① It is flexible and impact-resistant, and fits the curved surface design perfectly (solving the pain point of warping of curved-edge furniture); ② The density is 15% lower than PVC, which reduces the burden on the board; ③ It is resistant to high temperatures and does not deform, and the surrounding area of the kitchen stove is more stable-in contrast, PVC is only suitable for straight edges and is easy to soften at high temperatures. In long-term use, ABS is resistant to aging and yellowing, and its life is extended by 30%, while PVC is prone to brittle degumming and has higher hidden costs.

Although the price of ABS is 5%-8% higher than that of PVC, its quality upgrade brings long-term benefits. As a Chinese factory with 22 years of experience, Luyao uses a direct sales model to increase your efficiency

Act now and contact Luyao sales team to get exclusive quote + free color card

|

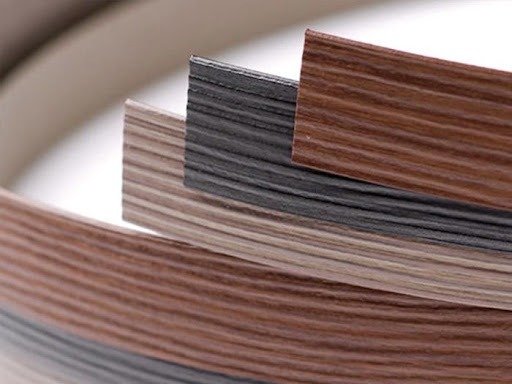

Melamine Edge banding

Melamine edge banding is based on resin-impregnated decorative paper, which is formed into a dense surface layer through high temperature and high pressure process, and is covered with a uniform pre-coated hot melt adhesive layer. Its unique texture and matte texture perfectly simulate natural materials.

Customized service

Luyao supports free width slitting and provides two packaging forms: roll or straight strip. The minimum order quantity is one container. Designers can match the texture with the samples you provide, and we can complete the sample proofing and send it out within 72 hours.

Quality Commitment

We have passed ISO 9001 quality system certification. Each roll of edge banding has been tested by:

① Colorimetric spectrometer test

② Peel strength test (ASTM D903 standard)

③ -30℃/80℃ hot and cold cycle aging

Ensure that the product maintains glue activity for ≥24 months during transportation and storage

|

Acrylic Edge banding

Acrylic edge banding (scientific name: polymethyl methacrylate PMMA) is a top-level edge banding solution based on optical grade polymer. Its light transmittance ≥ 92% and Mohs hardness 3-4 provide furniture edges with a glass-like texture and the strength of engineering plastics. It is particularly suitable for high-end cabinets, commercial spaces and luxury display furniture. Of course, its price is more expensive than other edge bandings.

Surface effect

The pattern layer is buried deep under the 0.5mm transparent PMMA protective layer, and the depth of field is 1.2mm when the light penetrates. Luyao’s high-gloss and matte matte models can enhance the user’s experience.

Physical protection

Abrasion resistance of 1500 revolutions (3 times that of PVC edge banding), impact resistance of 15kJ/m², and more resistant to chemical corrosion of pH3-11.

2000+ texture library

From single color to double color, from solid color to wood grain, cloth grain, marble grain, special pattern, we can give you the product that best suits your market and customize it for your project

Luyao’s competitiveness stems from the integration of Germany’s Battenfeld production line and Japan’s Mitutoyo testing system: raw materials are screened for impurities by gas chromatograph, and the extrusion thickness fluctuation is <±0.03mm; the two-color interface is laser-positioned and welded (error <0.05mm) to achieve “microscope-level seamlessness”; each batch is tested by -40℃ deep freezing/120h boiling water boiling to ensure five-year outdoor weather resistance.

Provide EXW/FOB/CIF or shanghai, click the button below to get a quote !!!

Customize

We offer ODM/OEM services – from design and production to sales and integration – tailored to your exact specifications

Dimensions & Material Thickness

Brand Colors & Logo Integration

Packaging & Graphic Design

Contact Lu Yao to start your quality purchasing journey!

Exclusive for first order for a limited time!

First order of container edge banding? Luyao will give you the best price! Must reply within 12 hours!