What is Edge Banding and Its Uses?

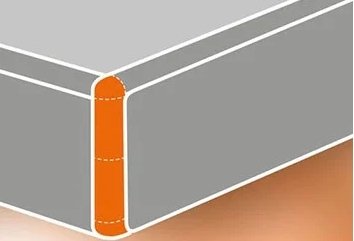

Edge banding is the process of sealing the raw, exposed edges of wood panels with a protective strip known as lipping. This technique plays a vital role in furniture making, as it not only enhances the durability of the product but also contributes to its overall aesthetic appeal. In carpentry, edge banding is often the final step in creating a polished, high-quality finish, ensuring that rough edges are neatly tidied up.

Understanding Edge Banding Basics

If you’ve ever observed furniture being crafted, you might have noticed that cut wood panels often have raw, exposed edges. These unprotected edges can lead to significant issues, as they allow moisture to seep in, causing the wood to warp, swell, or become uneven. This not only shortens the lifespan of the furniture but also detracts from its visual appeal.

Edge banding addresses these problems effectively. By applying a protective layer, edge banding shields wooden panels from moisture, thereby mitigating the effects of humidity and liquid spills. This simple yet effective solution greatly enhances the durability and longevity of your furniture.

What is Lipping or Edge Band?

Lipping, or edge banding, typically consists of a thin strip of impermeable material, such as PVC, acrylic, or ABS, cut to fit the size of wood-based panels like plywood, particleboard, or MDF. This strip is then adhered to the exposed edge using a strong adhesive. In commercial settings, edge banding is often completed using specialized machines known as edge banders, which apply hot-melt adhesives for a secure bond.

Lipping can be sourced in rolls of 200 meters, with thicknesses varying according to customer requirements. At Meru Timber, we offer edge banding in a range of thicknesses from 0.45mm to 1mm and beyond. Thicker lipping is especially beneficial in high-traffic areas, providing greater resilience and impact resistance. For instance, drawer fronts and doors may require a thicker 1mm PVC lipping for maximum durability.

How Does Edge Banding Protect Furniture?

Modular furniture is primarily constructed using wood-based panels, which, despite treatments to enhance moisture resistance, still have a natural tendency to absorb water. Edge banding plays a crucial role in protecting these panels. By sealing the edges, lipping reduces the effects of atmospheric humidity and liquid spills, thereby enhancing the strength and durability of the wood. So, the next time you accidentally spill a drink on your table, you can thank the edge banding for safeguarding the wood.

Edge banding serves both functional and aesthetic purposes. Functionally, it prevents moisture infiltration, acting as a seal on the core material’s edge. It also adds strength and shock protection, while aesthetically, it covers unsightly rough edges and creates a glossy finish that complements the overall design. Additionally, edge banding allows for the creation of rounded edges, softening sharp angles.

Different Types of Lipping for Various Materials

There are several edge banding materials available in the market, including PVC, ABS, acrylic, PP, PMMA, PET, and wood veneer. However, two of the most commonly used materials are PVC and ABS.

PVC Edge Banding

PVC (polyvinyl chloride) lipping materials are made from thermoplastic gum, offering both softness and durability. PVC edge banding is widely used in the construction of laminated and melamine cabinets and furniture. Known for its extensive range of color options that match laminate and melamine boards, PVC lipping is particularly popular for its glossy finishes and vibrant hues.

The advantages of PVC edge banding include:

- Affordability: It is cost-effective, making it accessible for various projects.

- Durability: PVC is long-lasting and resistant to wear.

- No Finishing Required: It does not need additional finishing processes.

However, there are some drawbacks to consider:

- Non-recyclable: PVC cannot be recycled.

- Non-biodegradable: It does not decompose naturally.

- Limited Refinishing Options: Once damaged, it cannot be refinished.

ABS Edge Banding

ABS (acrylonitrile butadiene styrene) edge bands share many characteristics with PVC, but they are lower in density and free from chlorine. ABS lipping is eco-friendly, recyclable, and thermally resilient, making it safe for incineration. This material is available in a variety of colors, finishes, and textures, providing versatility for various design needs.

Finding the Perfect Edge Banding

Whether you are a professional or a DIY hobbyist, sourcing quality edge banding is crucial for achieving the desired look and value of your furniture. It’s advisable to consult experts who can guide you in selecting the right width, thickness, and color.

At Meru Timber, we offer a wide selection of lipping tapes, including pre-glued options and 3D acrylic tapes, available in various thicknesses from 0.45mm to 3mm and a range of board thicknesses. Our materials include solid colors and wood grain designs, such as African Wenge, Esperanza Oak, and Cherry.

Edge Banding at Meru Timber

At Meru Timber, we are dedicated to helping you make informed decisions. We stock high-quality, commercially available lipping in over 90 colors, with a diverse range of finishes and patterns to choose from. Our PVC lipping materials are designed to match popular melamine boards like Timsales, Comply, PG Bison, and Rai plywood. We aim to be your one-stop shop for all edge banding needs.

Cost Considerations

When budget is a primary concern, we recommend PVC lipping due to its lower production costs. However, this material does not compromise on quality. For best results, we suggest using 1mm lipping, which ensures cleaner, faster application with superior adhesion, leading to a smooth, professional finish.

Pro Tips

In general, we advise against using 0.45mm edging for high-traffic areas, as the corners can be too sharp. This thinner lipping is more suitable for drawer boxes and light-use applications. For areas that experience heavy use, such as kitchen countertops, we recommend 1mm or even 3mm lipping for added protection.

Edge Banding with Hot Melt Adhesive

Using the right adhesive is crucial for a successful edge banding application. At Meru Timber, we utilize hot melt glue, which is user-friendly and provides an excellent seal. The primary options for hot melt adhesives are EVA (Ethylene Vinyl Acetate) and PUR (Polyurethane), each with its own advantages.

- EVA Adhesive: This multipurpose hot melt glue is suitable for various materials, including PVC, Melamine, ABS, and acrylic. It is affordable and easy to work with, though it offers standard resistance to heat and moisture.

- PUR Adhesive: This glue hardens once dry and creates a strong bond quickly, allowing for minimal mistakes. However, it requires fast application, as it sets rapidly.

Machinery Used in Edge Banding

Edge banding is performed using specialized machines called edge banders, which apply the lipping to the raw edges of wood panels with hot-melt glue. These machines can handle lipping up to 3mm thick and 50mm wide, ensuring a precise and seamless finish.

At Meru Timber, we use state-of-the-art machinery, including Casadei and European industrial edge banding machines, which can groove and round corners. Additionally, our cutting optimization software calculates the exact amount of lipping required for your project.

Conclusion

We hope this article has provided valuable insights into the edge banding process and its benefits. If you have any further questions or need assistance, feel free to leave a comment. Our team at Meru Timber is here to help you with all your edge banding needs!

Leave a Reply