Painting PVC Edgebanding

In woodworking, Painting PVC Edgebanding proves invaluable, especially when custom colors are needed. Once painted, it can be applied just like standard banding, ensuring a professional finish. We hope this guide has been helpful, and we wish you the best of luck with your projects!

If you need to paint standard PVC edge banding, scuffing and priming is essential. This can be done before or after applying the edgebanding to your panels.

Priming PVC Edgebanding:

- Use 220-400 grit sandpaper to lightly scuff the entire length of the banding. A palm sander is particularly effective for this task, as it avoids visible striations.

- Apply a primer formulated for plastics using a roller, brush, or sprayer. Once dry, your PVC edgebanding will be ready for painting.

Painting Techniques:

- Pre-Painting: Some woodworkers create custom tubular rolls to paint their edgebanding before application. The edgebanding is fed from its roll onto a rotating tube, allowing a long length to be spray-painted at once.

- Stack and Paint: Others prefer to paint the edgebanding after it has been applied. By stacking panels with edges flush, they achieve a uniform finish by painting them together.

- Get Creative: There are many solutions to woodworking challenges. Feel free to innovate and try something new!

What is Painting PVC Edgebanding?

Paintable PVC edgebanding is specially prepared for painting; it has been scuffed and primed, allowing immediate painting straight from the roll. This saves time for cabinet makers working with custom colors or needing to make repairs. Although manufacturers produce a wide variety of color-matched PVC edgebanding, maintaining a roll of paintable PVC is a smart practice for any woodworker.

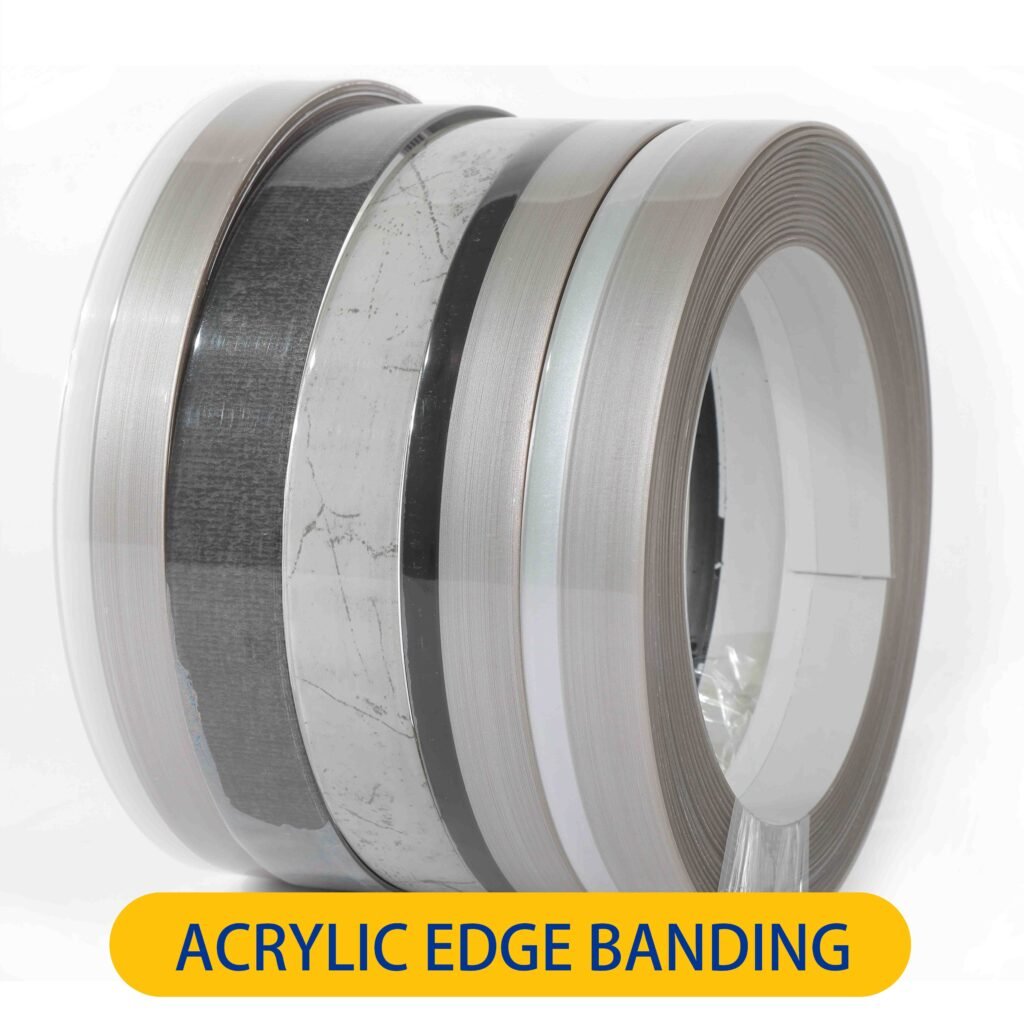

Advantages of Acrylic Edge Banding

Acrylic edge banding, made from high-grade thermoplastic (also known as 3D Acrylic or PMMA), offers several benefits:

- Modern Elegance: Its smooth surface enhances the visual appeal of furniture, cabinets, and panels.

- Enhanced Protection: It shields surfaces from impacts and wear, maintaining a polished look even in high-traffic areas.

- Easy Application: With a reliable adhesive backing, achieving a secure connection is straightforward, ensuring professional results without complicated tools.

- Versatile Style: Suitable for both contemporary and traditional designs, it adds sophistication to any environment.

- Lasting Appeal: Made from high-quality materials, it resists fading, ensuring your project remains attractive for years.

What Is Acrylic Edge Banding?

Acrylic edge banding is a durable, versatile edging solution perfect for high-wear areas. Its crystal clear appearance and unique 3D effect enhance the aesthetics of any application.

3D Edgebanding Features

3D Edgebanding is ultra-transparent acrylic with a special surface print on the reverse side, creating a three-dimensional effect. Key features include:

- Scratch Resistance: The unique finish remains intact even after milling, eliminating unattractive frame effects.

- Easy Repair: Physical damage such as scratches can be easily remedied by buffing.

- Hygienic and Impact Resistant: It withstands normal humidity and is easy to clean.

3D Edgebanding Applications

3D Edgebanding is versatile, suitable for various applications, including facings on kitchen and living room furniture, office desks, and shop fittings.

2-in-1 Edgebanding

Combining brushed aluminum with color-matched strips, 2-in-1 Edgebanding offers a high-gloss finish that resembles glass without the added cost and fragility. It’s ideal for modern kitchens and baths, providing a unique and sophisticated look.

3D Wave: Award-Winning Innovation

The 3D Wave range provides a remarkable depth impression through co-extrusion, featuring deeply embedded grain and a high-gloss surface. Available in fashionable colors, it enhances the appearance of spaces while being easy to clean.

Leave a Reply