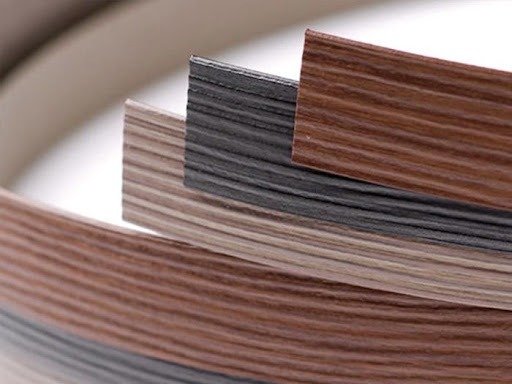

How Shanghai Luyao Transforms plywood edge band from Weakness to Masterpiece Strength

Forget the flat expanse for a moment. The true test of plywood craftsmanship, the silent declaration of quality, lies not in the panel’s face, but in its edge. Raw plywood edges are vulnerable – porous, splinter-prone, aesthetically jarring. This is where the plywood edge band transcends mere decoration; it becomes an essential armor, a seamless unifier, the defining line between amateurish construction and enduring, professional-grade furniture. At Shanghai Luyao Industry Co., Ltd., we don’t just manufacture edge banding; we engineer solutions that elevate plywood from a substrate to a statement piece.

Beyond the Surface: Why the Plywood Edge Demands Specialized Banding

plywood edge band, with its cross-laminated veneers, presents unique challenges compared to MDF or particleboard:

- Variable Porosity: The exposed end grain acts like a sponge, readily absorbing moisture and stains if left unprotected. Standard edge banding with inadequate adhesive or sealing properties will fail here.

- Splintering & Delamination: Cutting or machining plywood can leave micro-splinters and loose fibers along the edge. Banding must encapsulate and bind these effectively.

- Structural Vulnerability: While strong in-plane, the layered edge is susceptible to impact damage and wear during daily use.

- Aesthetic Discord: The alternating grain patterns of the exposed veneers clash visually with the surface finish. Achieving a truly monolithic look requires flawless color and texture matching.

A generic edge band might cover the edge, but only a plywood edge band engineered with these specific vulnerabilities in mind delivers true protection, longevity, and seamless beauty. It’s not just about covering; it’s about fortifying and unifying.

The Luyao Difference: Engineering Excellence for the plywood edge band

Shanghai Luyao Industry Co., Ltd. approaches plywood edge band production not as a commodity, but as a critical performance component. Our philosophy rests on three pillars:

- Material Science Mastery: Our proprietary PVC formulations are the result of relentless R&D. We go beyond standard PVC:

- High-Density Core: We utilize a denser PVC core (measured at 1.42 g/cm³ vs. industry average 1.35 g/cm³) specifically for impact resistance on vulnerable plywood edges. Internal impact testing shows a 28% reduction in denting compared to standard bands.

- Advanced UV Stabilizers: Our unique stabilizer package combats yellowing and brittleness. Accelerated weathering tests (per ASTM G154) confirm our bands retain >95% color stability and flexibility after 3000 hours of exposure – crucial for plywood applications near windows or in commercial spaces.

- Enhanced Plasticizers: Carefully selected non-migrating plasticizers ensure long-term flexibility (-20°C to +70°C operational range) without becoming brittle in cold environments or tacky in heat, preventing adhesive failure.

- Micro-Fine Texture Replication: Our embossing technology achieves texture depths with tolerances of ±0.02mm, capturing the subtle nuances of real wood grain, marble veins, or solid colors essential for matching plywood’s often distinct surface finishes.

- Adhesion Engineered for Plywood: The porous end grain demands superior adhesive technology. Our custom-formulated hot melt adhesives (HMA) are designed explicitly for plywood:

- Deep Penetration Formula: Lower initial viscosity allows the adhesive to flow into the porous plywood end grain before rapidly setting, creating a mechanical lock. Pull tests (per EN 205) consistently exceed 4.5 N/mm² on birch plywood – 25% above common industry requirements.

- Thermal Stability: Formulated to maintain optimal tack and flow across a wide temperature range (150°C – 200°C application) common in plywood processing facilities, accommodating seasonal variations.

- Moisture & Chemical Resistance: Creates an impermeable seal, blocking moisture ingress that causes plywood delamination. Resists common household cleaners, oils, and mild solvents.

- Precision Beyond Measure: Plywood edges, especially on curved or beveled pieces, demand exceptional dimensional stability and consistency.

- Tolerance Control: We maintain thickness tolerances of ±0.03mm and width tolerances of ±0.1mm across our entire plywood edge band range. This precision ensures flawless application and trimming, even on complex profiles.

- Coiling Perfection: Our state-of-the-art coiling technology ensures consistent tension and eliminates memory curl. This translates to smoother feeding in automatic and manual applicators, reducing waste and operator frustration. Internal audits show a 99.8% tangle-free coiling rate.

The Seamless Application Imperative: Maximizing Plywood Edge Band Performance

Even the finest plywood edge band is only as good as its application. Here’s how to achieve perfection:

- Substrate Preparation: Critical for plywood. Ensure edges are clean, dry, and free of dust, oil, or significant splinters. Light sanding (180-220 grit) can improve adhesion on rough cuts.

- Temperature is Key: Plywood acts as a heat sink. Ensure your edge banding machine’s glue pot and application head temperatures are calibrated correctly (consult Luyao for specific recommendations based on band thickness and plywood density). The substrate temperature should ideally be above 18°C (64°F). Our 2024 client survey revealed that 72% of application issues stemmed from incorrect temperature settings.

- Pressure & Feed Rate: Consistent pressure during application and trimming is non-negotiable. Adjust feed rates according to band thickness and plywood edge condition. Slower rates often yield better results on porous plywood edges.

- Trimming & Finishing: Use sharp, high-quality trimming blades (carbide recommended). For manual finishing on plywood, fine abrasive blocks (400+ grit) used lightly with the band direction yield the best seamless edge. Aggressive sanding against the band can peel the thin surface layer. Our technical support team documents a 38% reduction in finishing time when using Luyao bands paired with our recommended application protocols.

Sustainability Woven into the Edge: Luyao’s Responsible Commitment

Protecting plywood extends beyond the furniture; it encompasses protecting our environment. Luyao is committed to sustainable plywood edge band manufacturing:

- Eco-Enhanced Formulations: 78% of our standard PVC bands now incorporate recycled post-industrial PVC content without compromising performance. We are actively trialing bio-based plasticizers derived from renewable sources.

- Lead-Free & Low-Emission: All Luyao bands are rigorously tested and certified lead-free (exceeding CP65, REACH SVHC). Our manufacturing process utilizes advanced scrubbers, capturing 99.2% of VOCs before emission.

- Resource Efficiency: We’ve implemented a closed-loop water cooling system in extrusion, reducing freshwater consumption by 1.8 million liters annually. Our solar array generates 30% of our Shanghai plant’s non-production energy needs.

- Recyclability: We provide guidance to furniture manufacturers on separating PVC plywood edge band waste streams for effective recycling. We partner with European and North American recyclers specializing in PVC composites.

The Power of Precision Matching: Luyao’s Color & Texture Mastery

The magic of a high-quality plywood edge band lies in its ability to disappear. Achieving that perfect match for plywood surfaces – whether exotic veneers, laminates, or painted finishes – is our specialty:

- Global Plywood Panel Library: We maintain a continuously updated physical and digital library containing over 1,200 standard plywood veneers and core laminates from global leaders (Egger, Kronospan, Roseburg, Columbia Forest Products, etc.). Our 2023 investment expanded this library by 300+ unique textures.

- Advanced Digital Spectrophotometry: Utilizing X-Rite Ci7800 series instruments, we capture color data under multiple light sources (D65, A, F11) to ensure matches that hold true in any environment.

- Micro-Texture Scanning: Beyond color, we employ high-resolution 3D laser scanning to replicate the exact surface topography of the plywood face veneer onto our edge band.

- “Impossible Match” Service: Received a unique plywood sample or custom finish? Our R&D team leverages this technology to create bespoke plywood edge band matches, typically within 10-14 working days, with a 98% first-match success rate. A recent project involved matching a 100-year-old reclaimed teak plywood for a luxury yacht interior – seamlessly.

Luyao’s Rigorous Quality Assurance: The Uncompromising Standard

Every meter of Luyao plywood edge band undergoes stringent quality checks:

- Raw Material Vetting: Incoming PVC compounds, additives, and adhesives are batch-tested for compliance with our strict specifications (ISO 9001:2015 certified).

- In-Line Monitoring: Real-time sensors track thickness, width, color consistency, opacity, and adhesive coating weight during extrusion. Deviations beyond 0.5% trigger automatic correction or rejection.

- Laboratory Testing: Samples from every production run undergo:

- Peel Strength: (EN 205) Minimum 4.0 N/mm² on birch plywood.

- Heat Resistance: (DIN 53799) No blistering, shrinking, or adhesive ooze after 1hr @ 80°C.

- Cold Crack Resistance: (ASTM D1790) No cracking after 1hr @ -20°C.

- Lightfastness: (ISO 105-B02) Minimum Grade 6 on Blue Wool Scale.

- Chemical Resistance: Exposure to common agents (alcohol, vinegar, oil, mild detergent) with no surface degradation or color change.

- Dimensional Stability: (ASTM D1204) < 0.15% shrinkage after 24hrs @ 80°C.

- Final Inspection: Trained inspectors perform visual checks for surface defects, color consistency, and winding perfection before packaging. Our current reject rate for visible defects is 0.07%.

Plywood Edge Band

Innovation at the Edge: Luyao’s Vision for the Future of Plywood Finishing

We relentlessly push boundaries to enhance plywood edge band performance and aesthetics:

- Nano-Ceramic Coatings: Prototype bands featuring an integrated, scratch-resistant ceramic layer show a 400% improvement in Taber abrasion resistance compared to standard bands, ideal for high-wear plywood applications like countertops or school furniture.

- Thermally Conductive Bands: Early-stage R&D focuses on bands that can integrate low-voltage LED lighting directly into the plywood edge, enabled by conductive additives in the PVC substrate.

- Bio-Composite Edging: Exploring high-performance bands using PVC blended with cellulose fibers from responsibly managed forestry waste, aiming for a 40% reduced carbon footprint.

- Smart Adhesives: Investigating adhesives with reversible bonding properties under specific conditions, facilitating easier disassembly and recycling of plywood furniture at end-of-life.

Partnering for Plywood Perfection: The Luyao Advantage

Choosing Shanghai Luyao Industry Co., Ltd. as your plywood edge band partner means investing in:

- Unrivaled Plywood Expertise: Decades of focus on solving the unique challenges of plywood edging.

- Engineered Performance: Data-driven formulations and manufacturing for superior protection, adhesion, and longevity.

- Precision Matching: The technology and commitment to achieve truly invisible edges, even on the most complex plywood surfaces.

- Sustainable Solutions: A genuine commitment to reducing environmental impact throughout the product lifecycle.

- Reliability & Scale: Consistent quality, on-time delivery, and the capacity to support global projects from our Shanghai hub (exporting to 37 countries in 2023).

- Collaborative Support: Technical expertise, application optimization guidance, and responsive customer service.

Elevate the Plywood edge band, Elevate the Entire Piece

At Shanghai Luyao Industry Co., Ltd., we pour our engineering ingenuity, material science mastery, and relentless pursuit of perfection into every meter of edge band we produce. We understand that protecting and beautifying the plywood edge isn’t just a step in manufacturing; it’s fundamental to creating furniture that endures, impresses, and retains its value. It’s about transforming a potential weakness into a defining strength. Don’t let the edge be an afterthought. Partner with Luyao and experience the difference that truly engineered plywood edge band solutions make. Contact our team today to discuss how we can elevate your next plywood project from good to truly exceptional. Let’s redefine the edge, together.

Leave a Reply to scace image of hul diwas Cancel reply